Chain transmission device

一种链传动、链轮的技术,应用在传动装置、卷扬装置、便携式提升装置等方向,能够解决振动以及噪音变大、振动噪音变大、制造成本增加等问题,达到降低制造成本、振动以及噪音降低、噪音降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

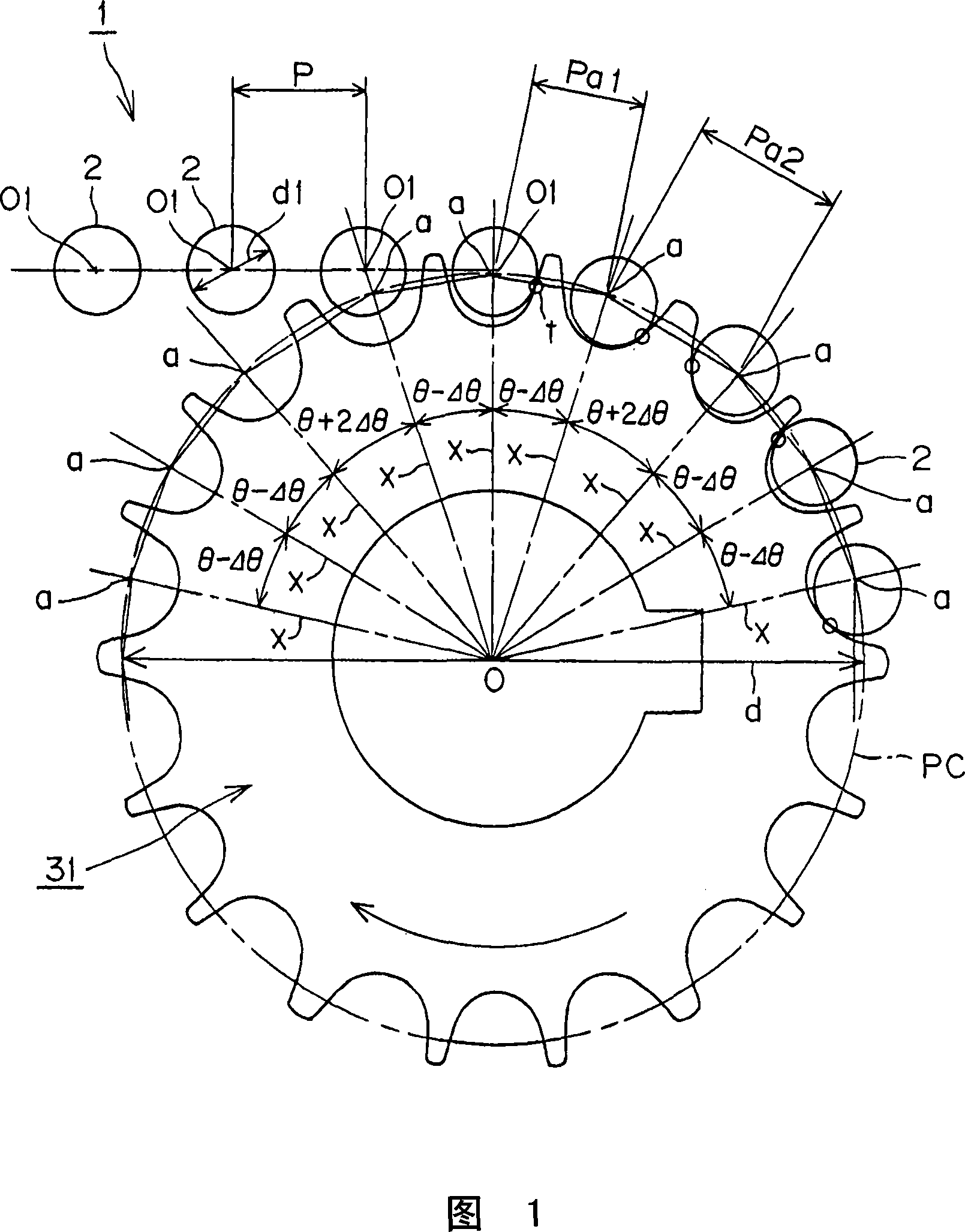

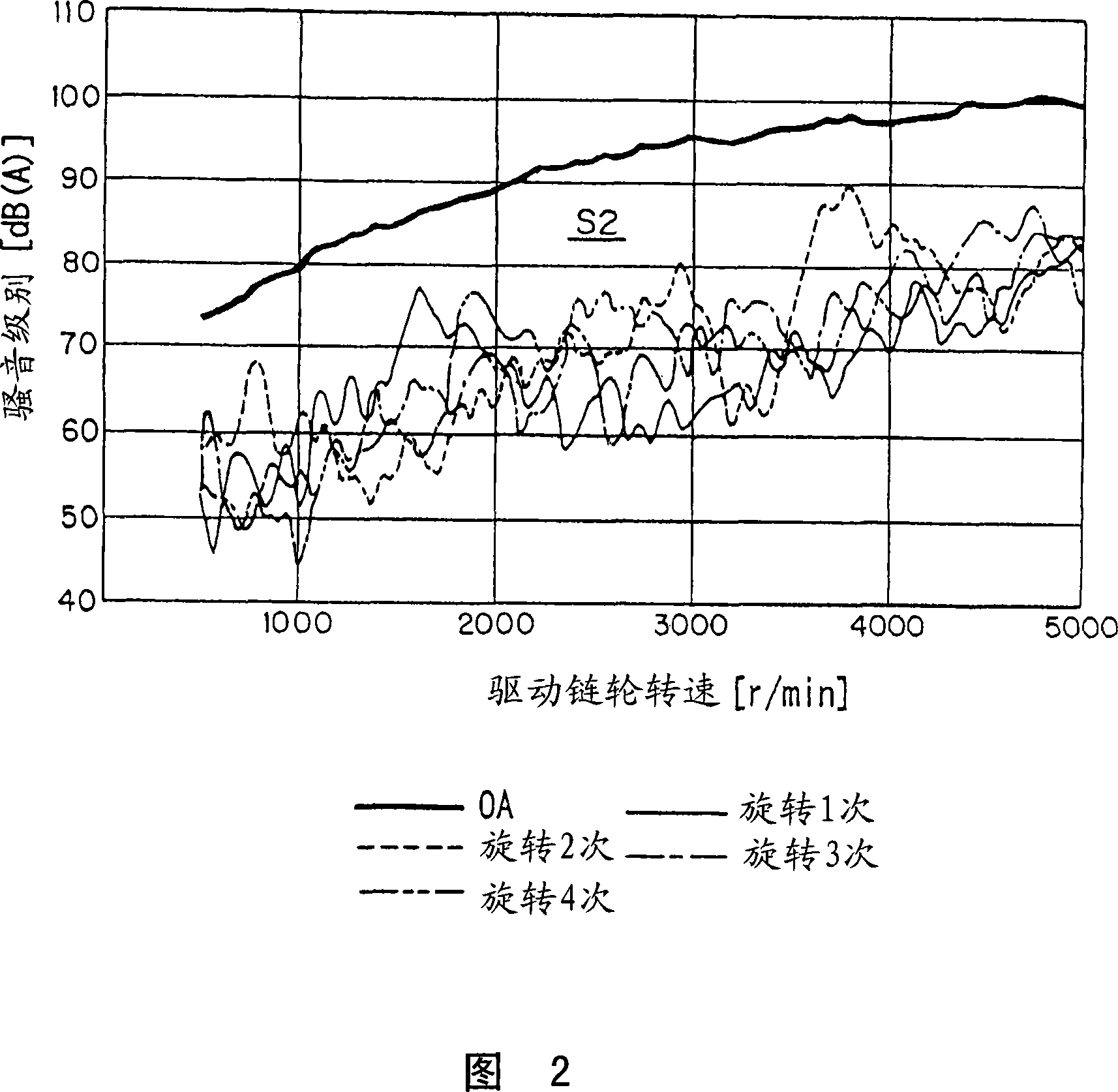

[0054] Next, the chain transmission device according to Embodiment 1 of the present invention will be described with reference to FIG. 1 and FIG. 2 . Fig. 1 is a front view showing a part of a meshing state of a standard roller chain and a sprocket of a chain transmission according to Embodiment 1 of the present invention. Fig. 2 is a graph showing the results of noise measurement of the chain transmission according to Example 1 of the present invention.

[0055] As shown in FIG. 1 , the chain transmission according to Embodiment 1 of the present invention includes a standard roller chain 1 and a sprocket 31 in which the rollers 2 of the standard roller chain 1 mesh with teeth.

[0056] As mentioned above, the standard roller chain 1 has: an inner chain link, the two ends of the two sleeves are respectively pressed into the sleeve holes of a pair of inner plates, and the roller 2 with an outer diameter of d1 is rotatably nested in the sleeve. On the outer circumference of the...

Embodiment 2

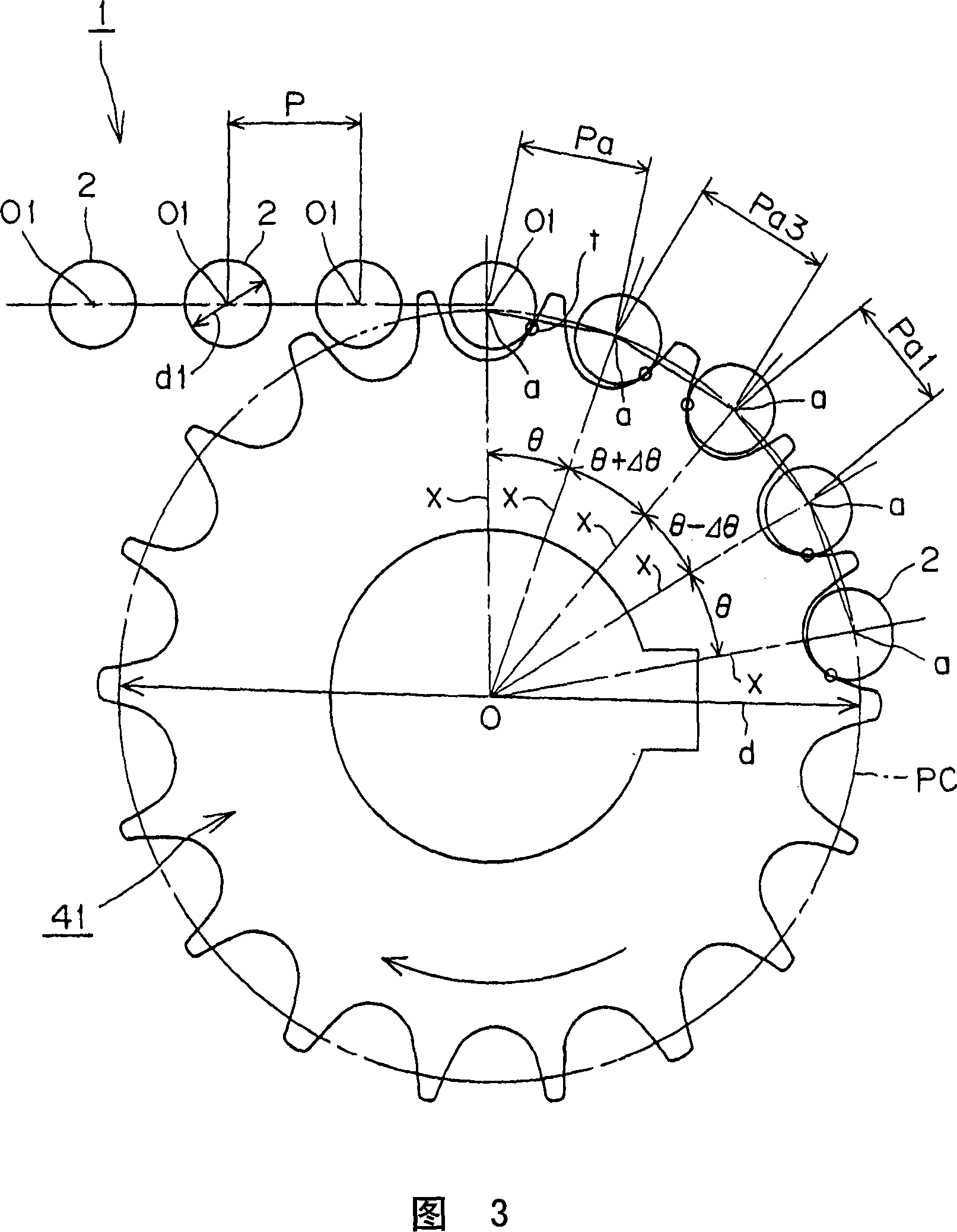

[0067] Next, a chain transmission device according to Embodiment 2 of the present invention will be described with reference to FIG. 3 . 3 is a front view showing a part of the meshing state of the standard roller chain and the sprockets of the chain transmission according to Embodiment 2 of the present invention.

[0068] As shown in FIG. 3 , the chain transmission according to Embodiment 2 of the present invention includes a standard roller chain 1 and a sprocket 41 in which the rollers 2 of the standard roller chain 1 mesh with teeth.

[0069] The standard roller chain 1 is as described in Embodiment 1 of the present invention, and thus its description is omitted.

[0070] The sprocket 41 differs only in that it has three different tooth pitch angles from the first embodiment of the present invention having two different pitches θ-Δθ and θ+2Δθ. As described above, for the convenience of the following description, the pitch angle θ of the teeth determined by the formula θ=3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com