Method for controlling automatic lifting of gyro-theodolite sensitive part

An automatic lifting and theodolite technology, which is applied in theodolite, gyroscope/steering sensing equipment, gyro effect for speed measurement and other directions, can solve the problems affecting the accuracy and speed of orientation, and achieve the effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples.

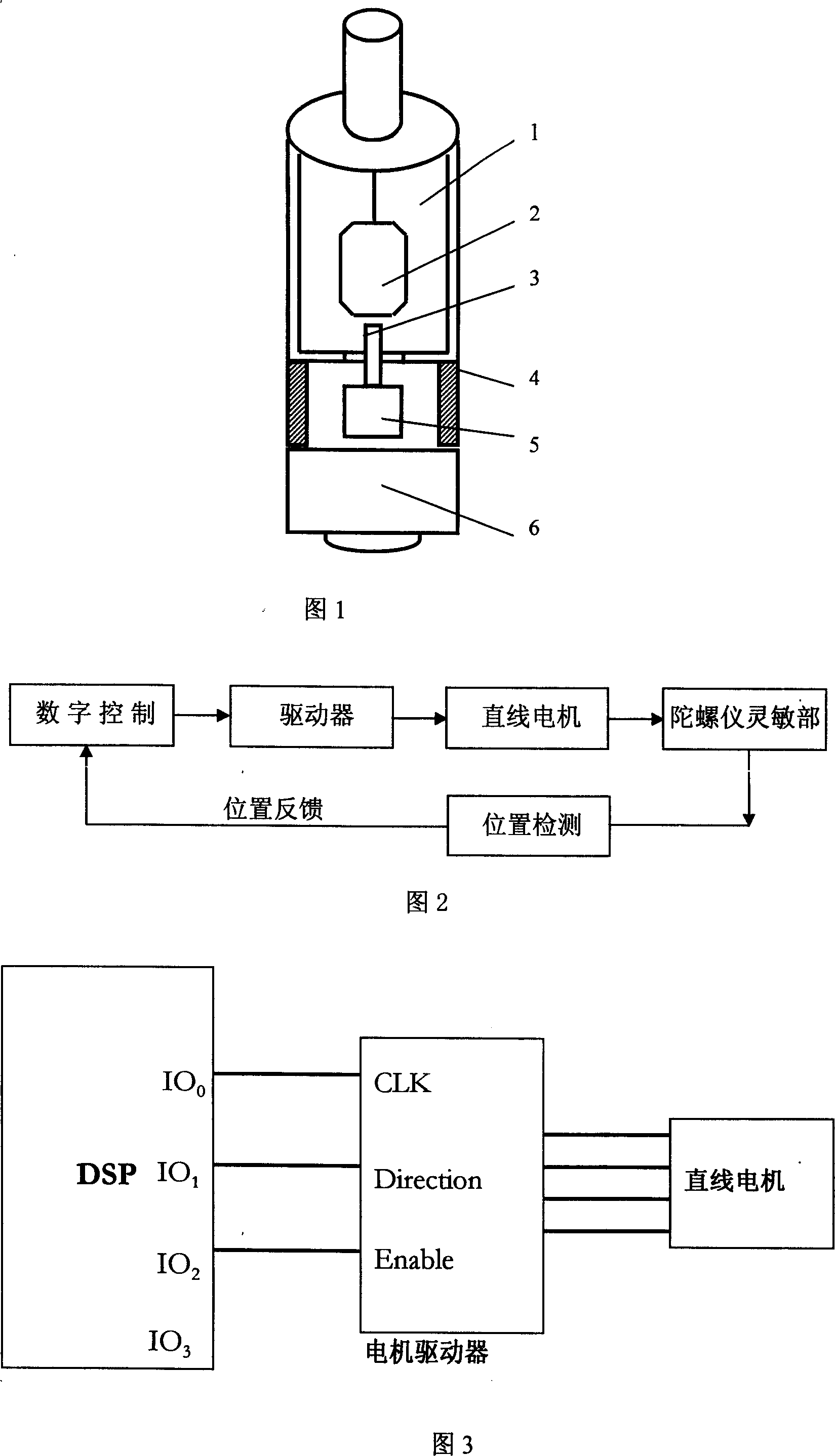

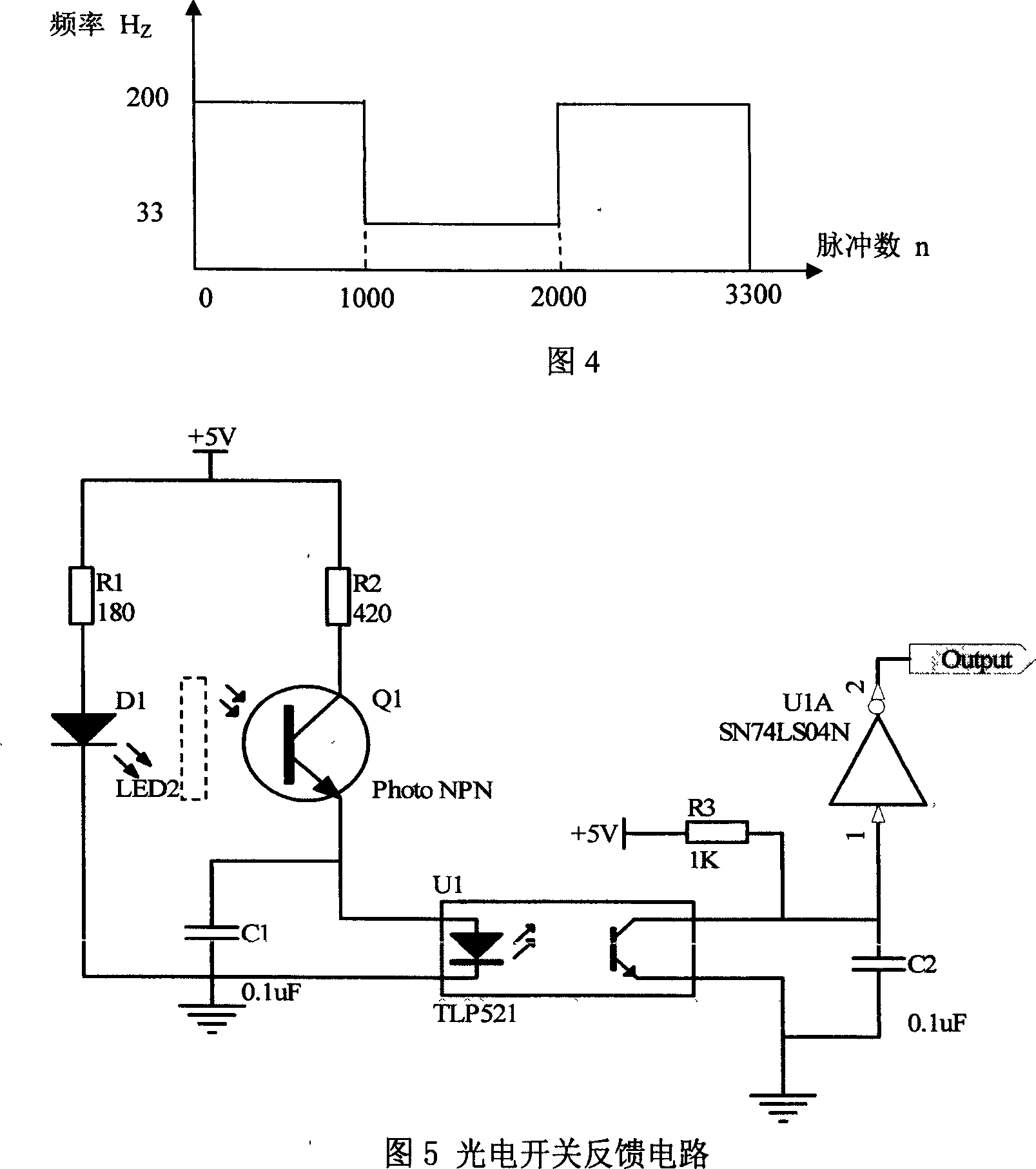

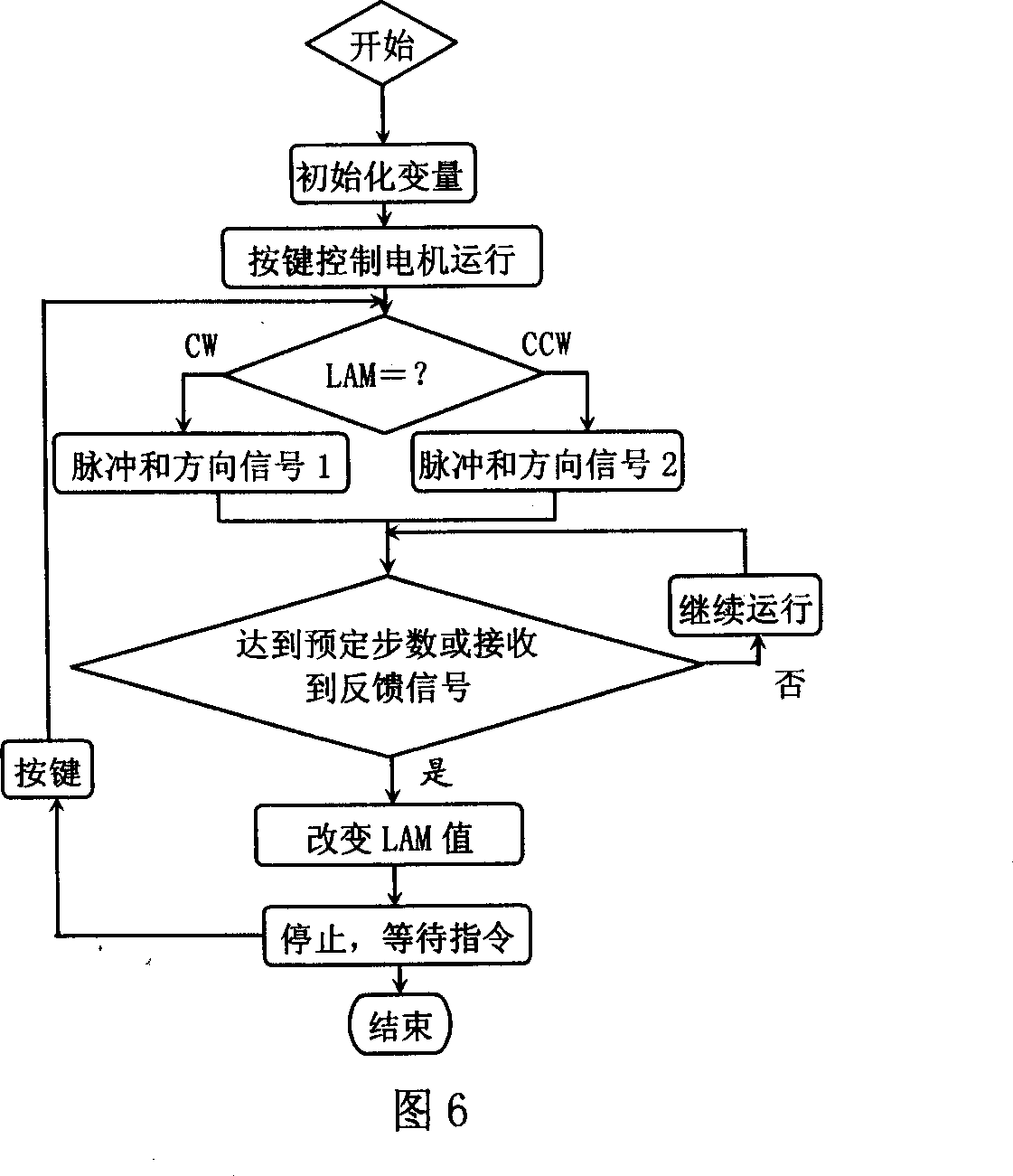

[0021] The automatic lifting system of the sensitive part of the gyro theodolite is based on the digital gyro intelligent north-seeking system. The cursor signal is processed by the intelligent north-seeking system to realize the automation of reading; the pulse and direction signals for controlling the linear motor are generated by the DSP (Digital Signal Processor) processing module. The structure of the automatic lifting system of the sensitive part of the gyroscope is shown in Figure 2. The digital control adopts DSP model TMS320F206; the driver is DCS4020 bipolar chopper, which adopts half-step control; the linear motor model is 28F47-05-012, and the motor step length is 0.003175mm; the gyroscope adopts JT- 15 Gyroscope; position detection adopts photoelectric switch H105. The DSP sends pulse and direction signals to the motor driver, the driver con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com