Three way catalytic converter critical aging test method

A three-way catalytic converter and aging test technology, which is applied in the testing of machine/structural components, instruments, and engines, etc., can solve the problems of poor response time of oxygen sensors, and achieve the effect of low cost and shortened development time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

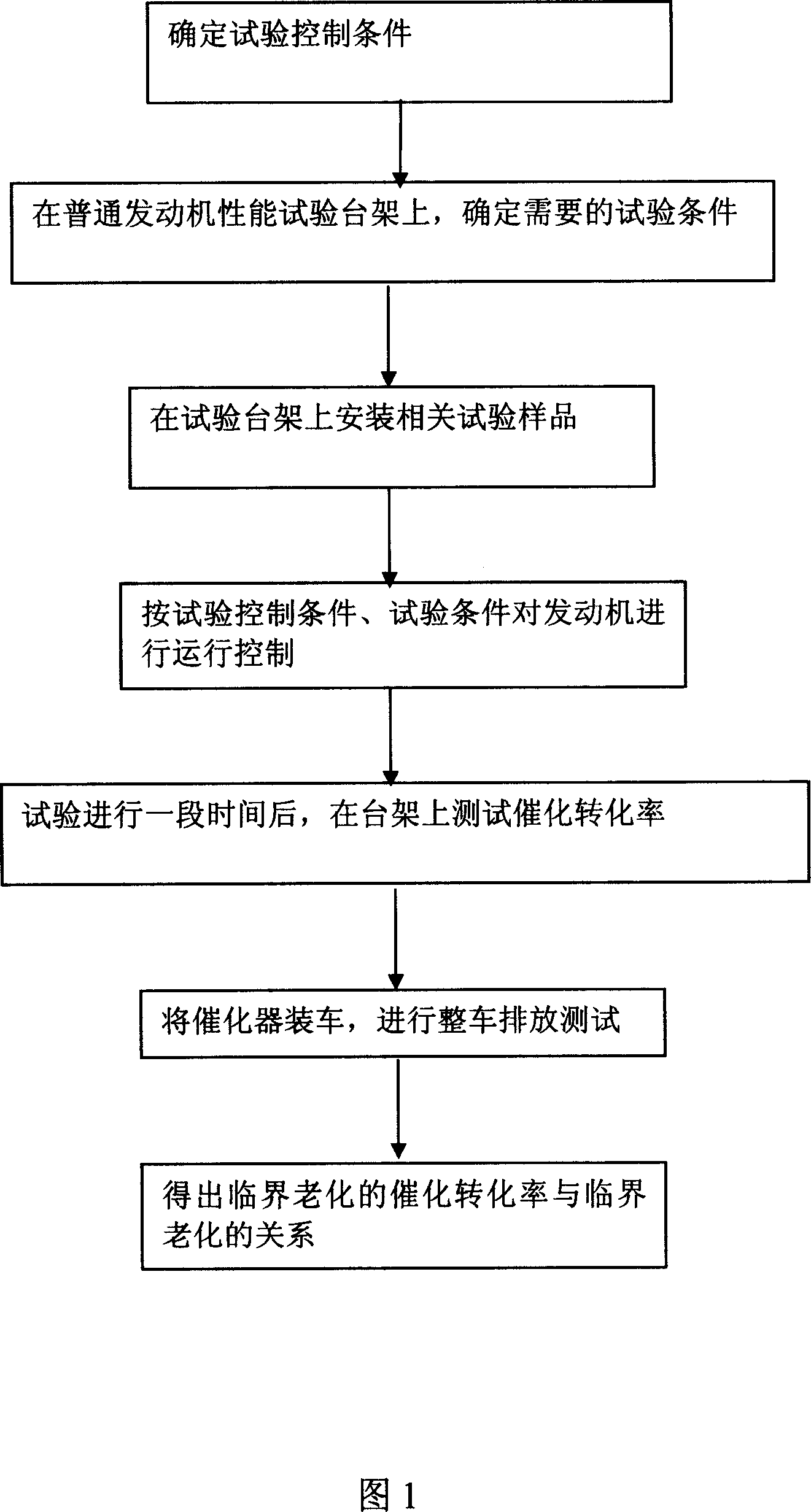

[0026] The present invention will be further described in detail through specific embodiments below.

[0027] Step 1: Determine the test control conditions;

[0028] According to the chemical properties of the three-way catalytic converter, when the operating temperature is 700°C-800°C, the combustion products of the mixture gas under the closed-loop control of EMS and the combustion products of the mixture gas are lean, which will easily cause the three-way catalytic converter to age. According to the research of Delphi (delphi), under the working condition of lean mixture, the working time of the catalytic converter shall not exceed 1% of its life time; and according to the technical requirements and test methods of GB / T18377 gasoline vehicle catalytic converter , it was decided to use an engine test bench to age the three-way catalytic converter.

[0029] The experimental control conditions are as follows:

[0030] serial number

Condition

Operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com