Empty bottle mouth defect inspection method and device

A detection device and technology for empty bottles, applied in the field of crown beer bottles, can solve the problems of slow speed, inability to maintain constant standards, ambiguous manual detection standards, etc., and achieve the effects of simple structure, high recognition rate automatic detection, and high efficiency rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

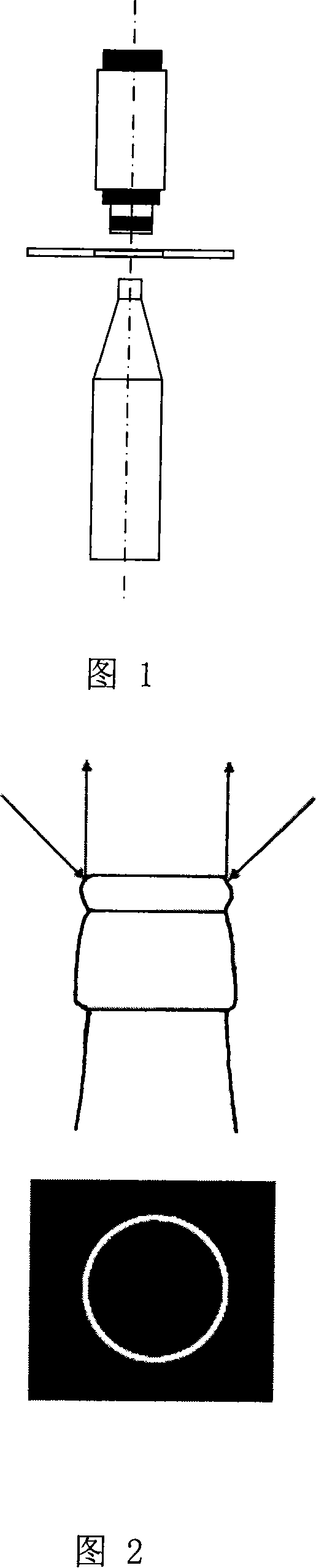

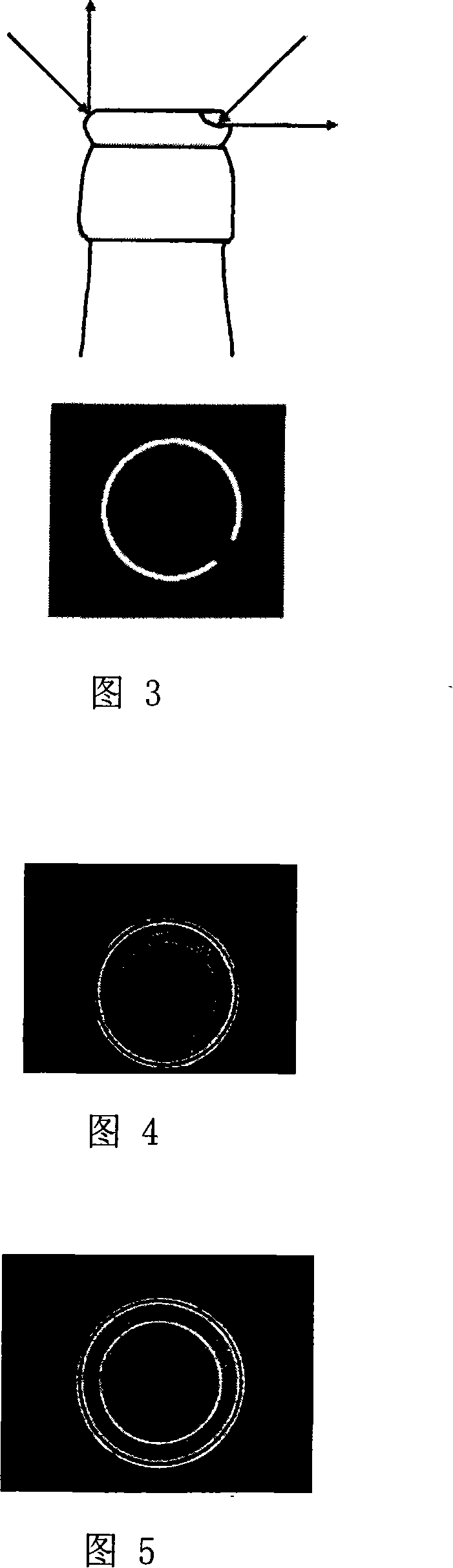

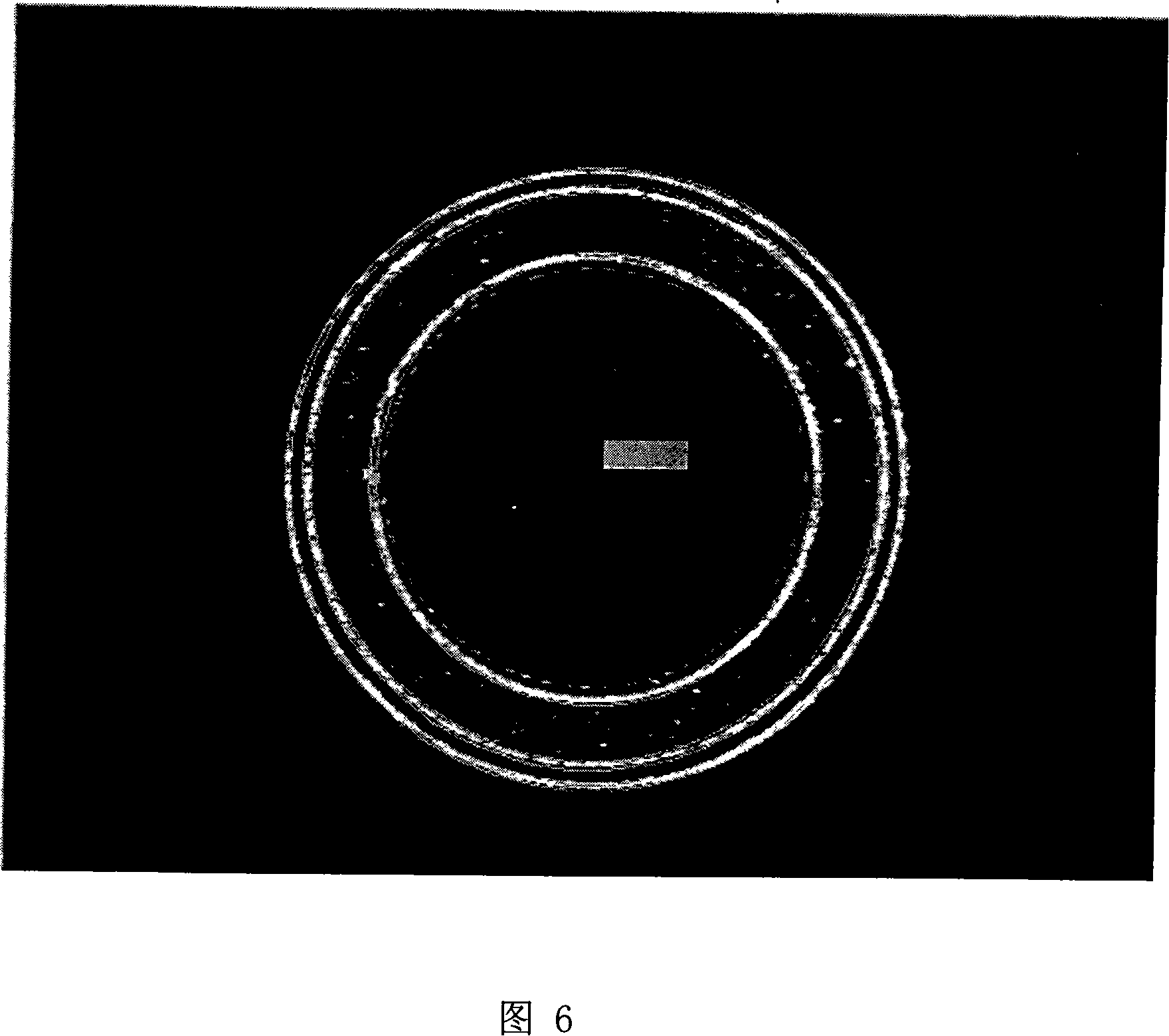

[0035] The device of the invention is a part of the multi-sensor machine vision online detection system, and can be separated into an independent system. The hardware composition of the whole system is shown in Figure 9. The structure of the system consists of a transmission mechanism (such as a conveyor belt), a photoelectric sensor (photoelectric switch), a camera system (industrial-grade high-definition camera system), an image processing system, and a controller (such as a PLC). ) and industrial computer (industrial control computer). Wherein the camera system includes a camera (such as a CCD camera) whose shooting direction is facing towards the mouth of an empty bottle to be detected, and a light source and a strobe controller that cooperates with the light source, the camera and the strobe controller are respectively connected with the control The device is electrically connected, and the light source is specifically a ring-shaped LED light source surrounding the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com