Lens assemblage machine

A lens group and alignment device technology, which is applied in installation, optics, instruments, etc., can solve the problems of dust particles sticking, lower assembly yield, module dropping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further illustrate the present invention, a preferred embodiment is described in detail below in conjunction with the accompanying drawings.

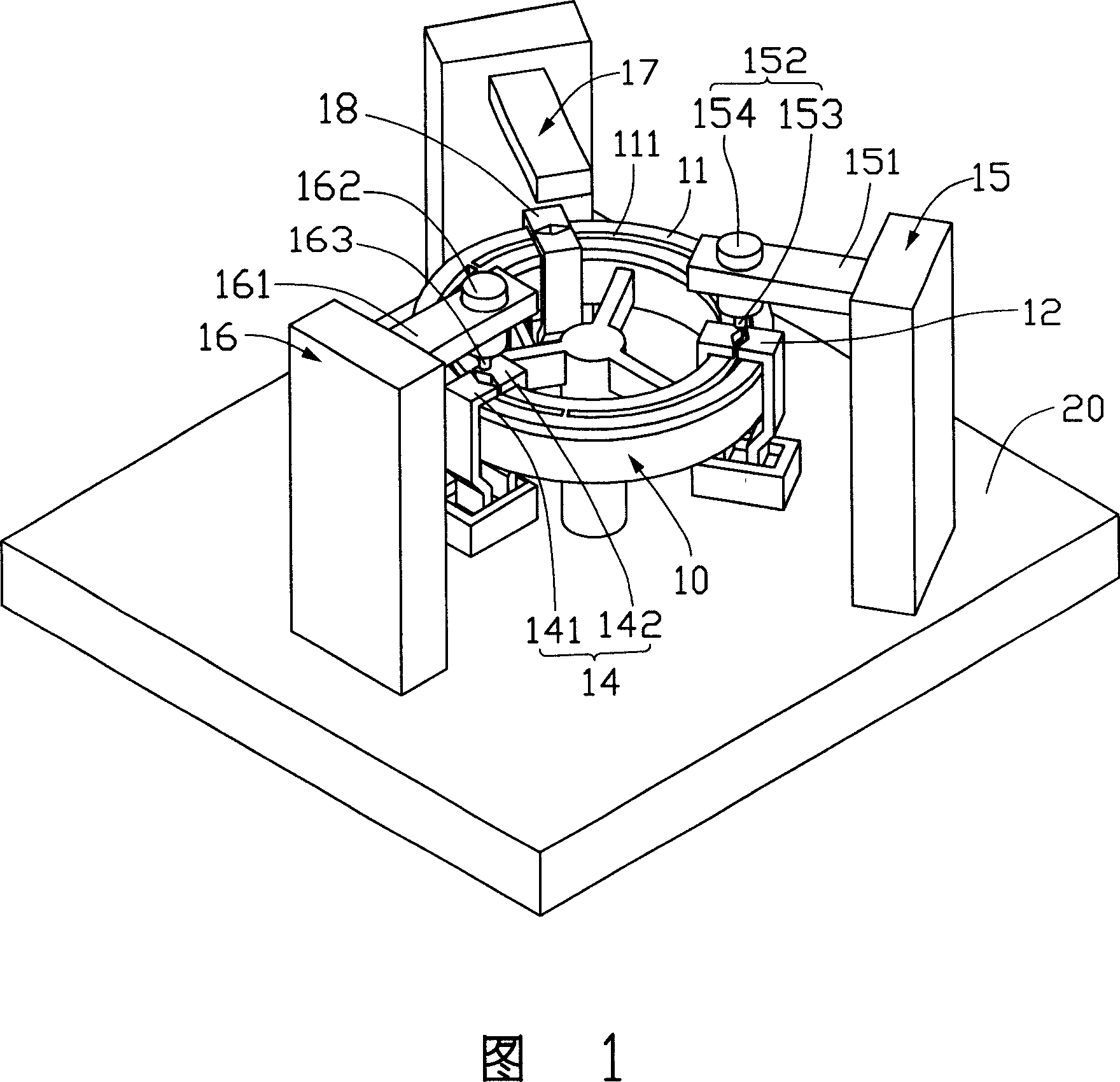

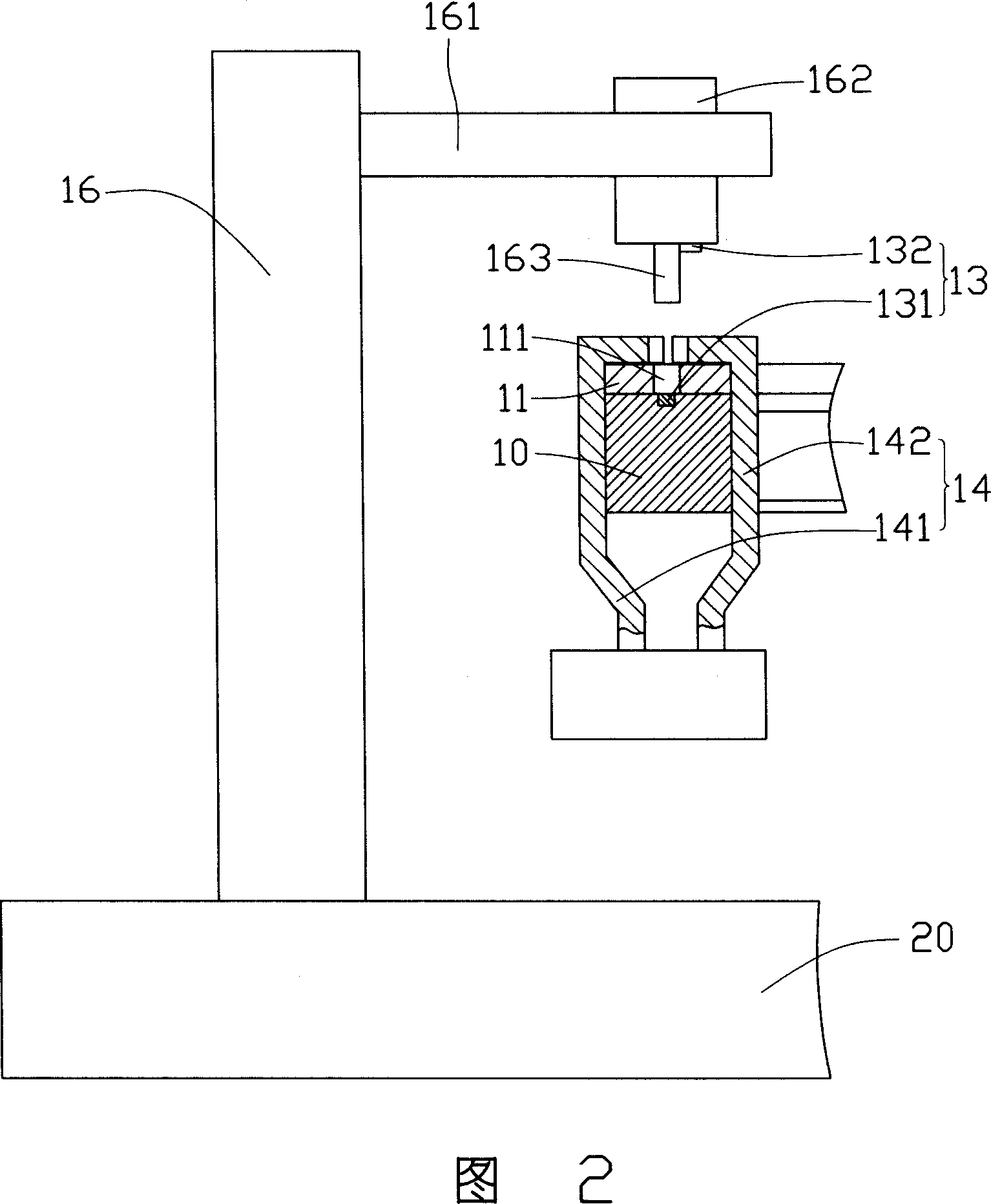

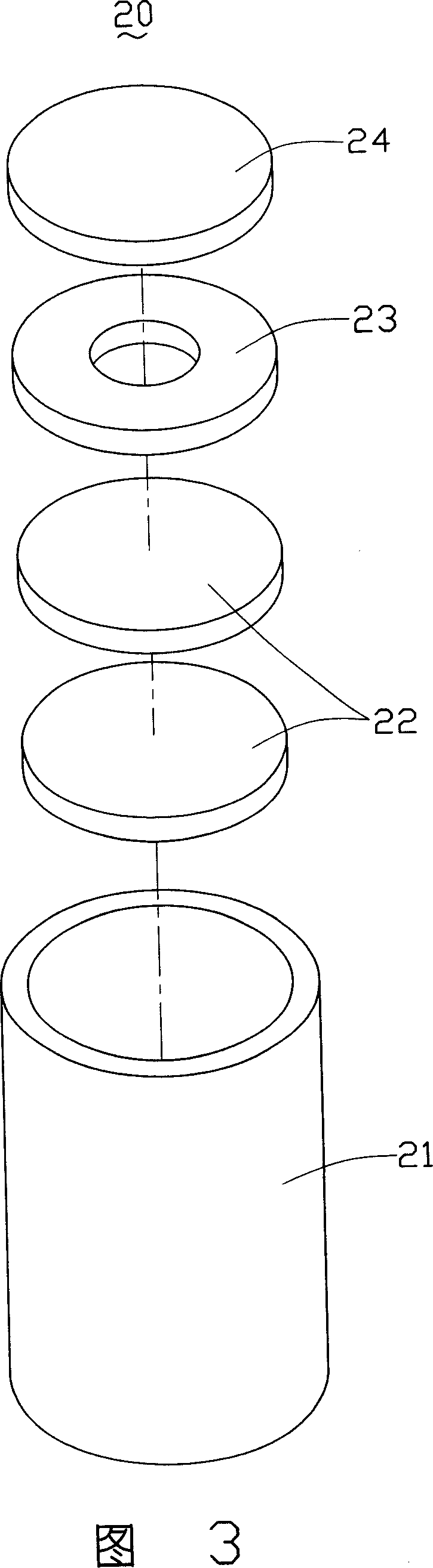

[0012] 1 and 2, the lens assembly machine of this embodiment includes a workbench 10, a conveying device 11, a first alignment device 12, a second alignment device 14, a third alignment device 18, and a plurality of The sensor 13 and the base 20. The lens assembly machine further includes a glue dispensing station 15 which is arranged on the base 20 and is used for dispensing glue; a curing workstation 16 which is arranged at The base 20 is used for curing operations; at least one part work station 17 is set on the base 20 and used to assemble corresponding parts.

[0013] The workbench 10 is set on a base 20.

[0014] The conveying device 11 is arranged on the workbench 10 and can be rotated on the workbench 10. There are a plurality of narrow gaps 111 in the middle of the conveying device 11, and the conveying device 11...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap