Flat form battery

A flat-shaped battery technology, applied to battery components, circuits, electrical components, etc., can solve the problems that external equipment and batteries cannot be connected, external equipment cannot be installed, and the external size of batteries increases, so as to reduce material costs , to prevent the corresponding reduction, to suppress the effect of external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

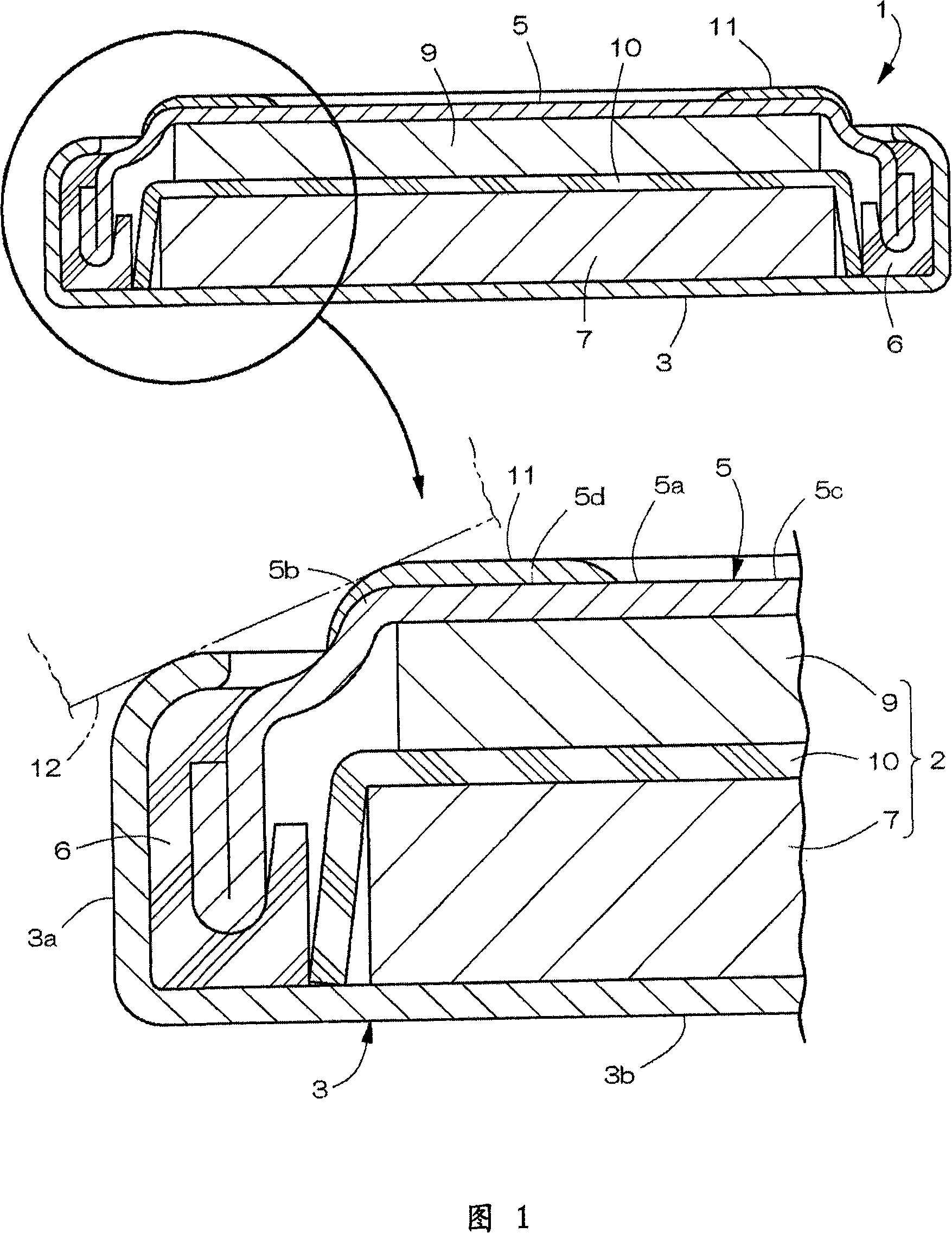

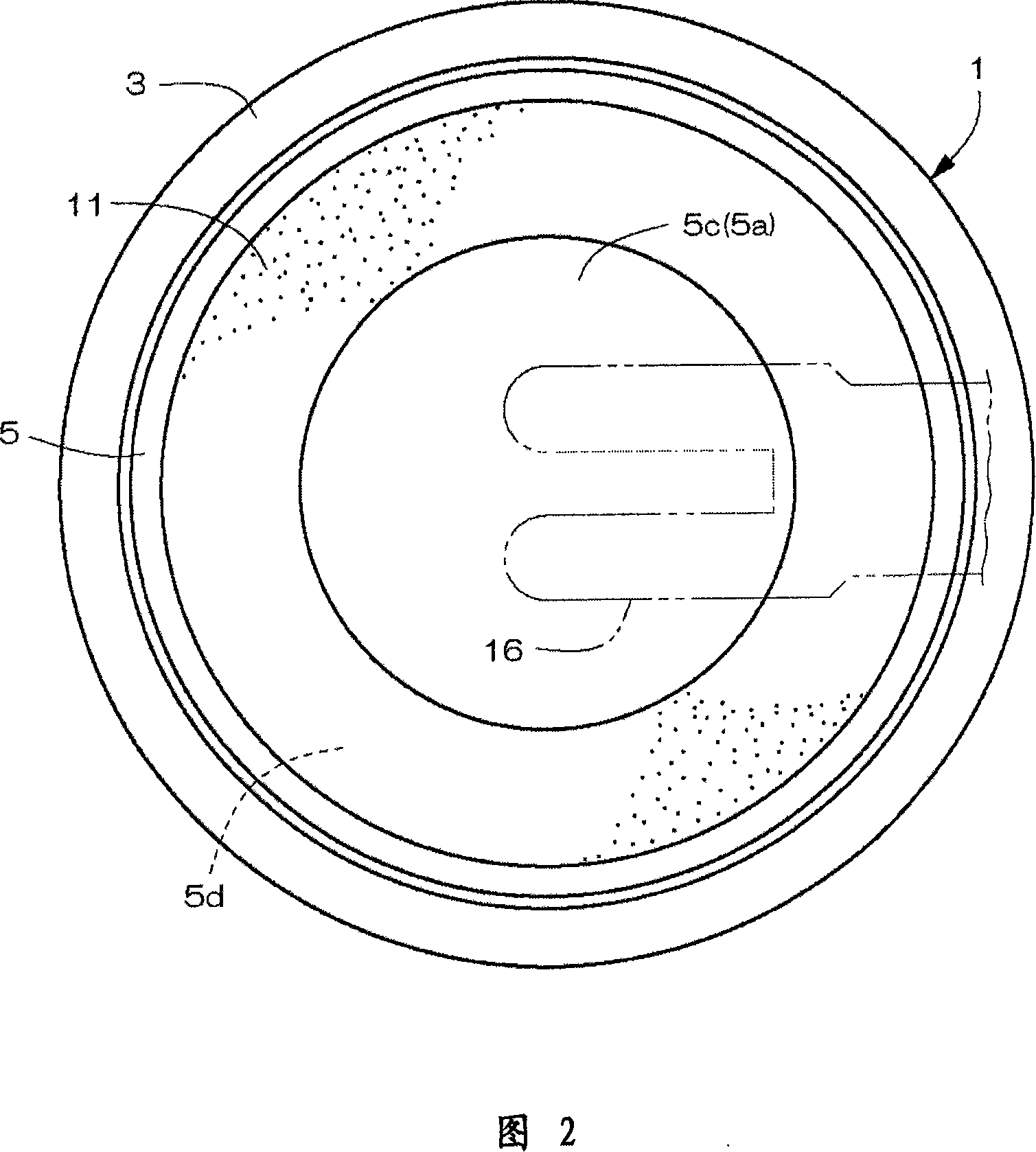

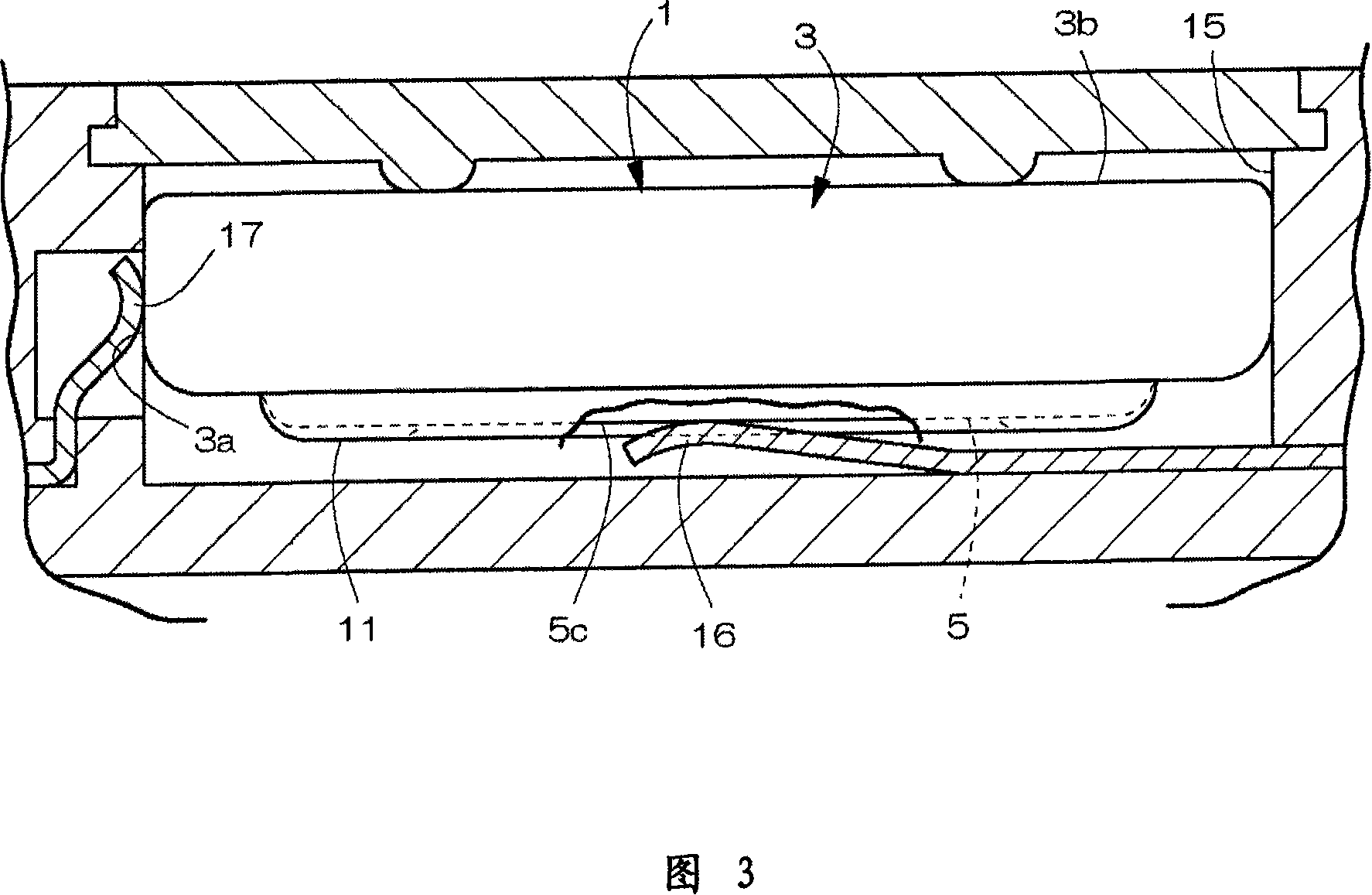

[0029] The drawings show an example of a primary battery which is a flat battery which is the object of the present invention. As shown in FIG. 1 , the battery container 1 is composed of an upwardly opening shallow dish-shaped positive electrode case (outer case) 3 and a downwardly opening shallow dish-shaped negative electrode case (sealing cover) 5, and the whole is made into a flat coin shape. The nominal voltage of the above-mentioned flat battery is 3V. Inside the battery container 1 , the power generating element 2 is accommodated, and an annular gasket 6 is arranged between the positive electrode case 3 and the negative electrode case 5 .

[0030] And, under the state that the power generation element 2 is accommodated inside the positive pole case 3, the negative pole case 5 is inserted into the opening inner edge side of the positive pole case 3 via the gasket 6, and fixed by riveting (the state of FIG. 6 The battery container 1 is sealed between the positive electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com