Synthetic leather with split leather as substrate

A synthetic leather and substrate technology, applied to synthetic resin layered products, crafts for producing decorative surface effects, decorative arts, etc., can solve problems such as excessive cost and trouble, poor physical properties, and increased waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the structure and the achieved effects of the present invention in detail, the following preferred embodiments are given below together with the accompanying drawings.

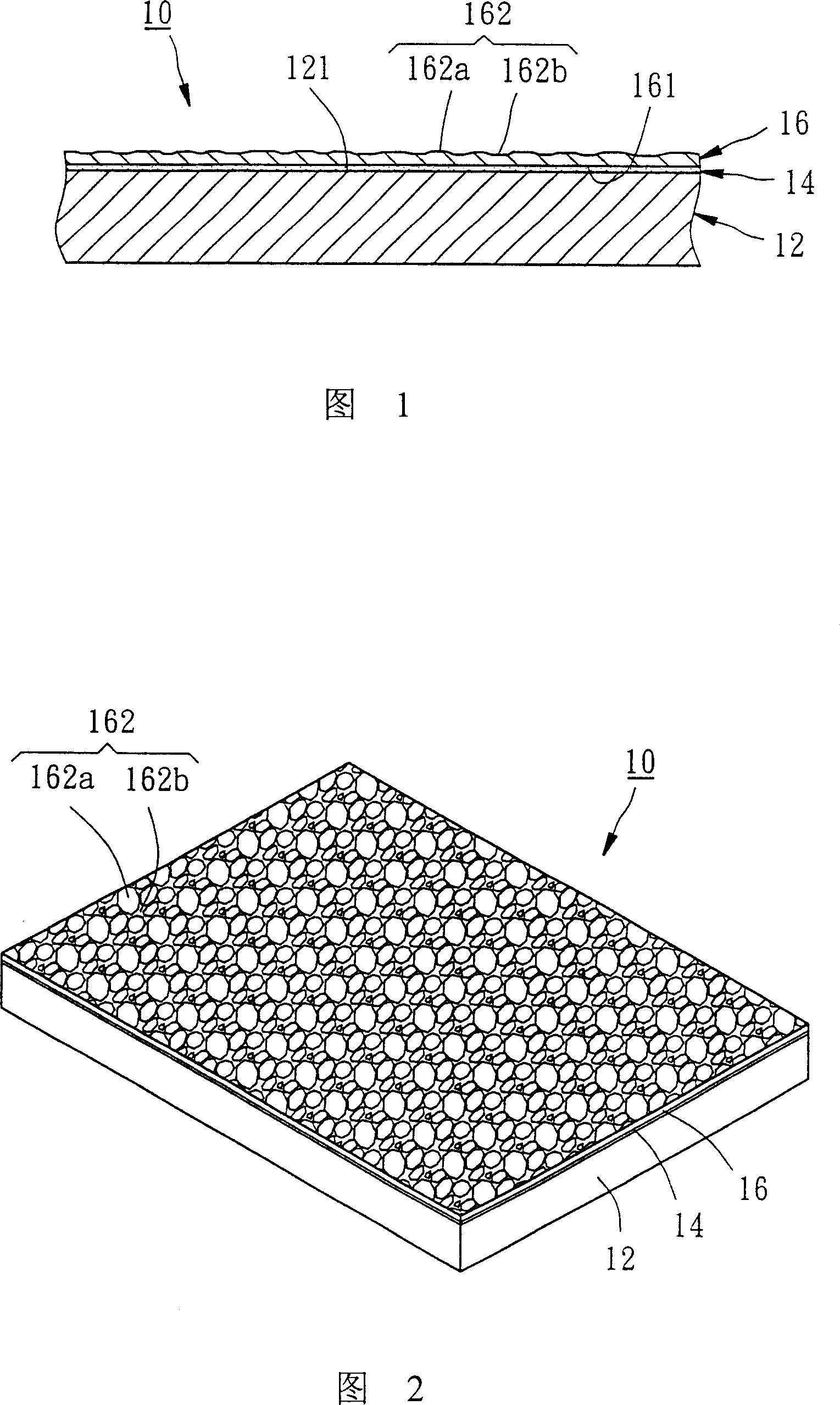

[0021] As shown in Fig. 1 and Fig. 2, it is the synthetic leather 10 of the first preferred embodiment of the present invention, which includes a base 12, an intermediate layer 14 and a covering layer 16, wherein:

[0022] The base 12 is made of palm skin taken from animal skins such as pigs, cows, sheep, elephants or crocodiles, and the present embodiment takes pigskin as an example. The taken-out husk is then subjected to treatment procedures such as water removal and deodorization to make the base 12 required in this embodiment. Its structure is tighter than before, so as to improve its water resistance and flame resistance, and to give synthetic leather 10 Tensile properties.

[0023] The middle layer 14 is coated with PU (polyurethane) resin on the top surface 121 of the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap