Automatic control device of tire pressure

An automatic control device and tire pressure technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve problems such as tire blowout, increased fuel consumption, abnormal hot tires, etc., to prevent traffic accidents, prolong service life, The effect of saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

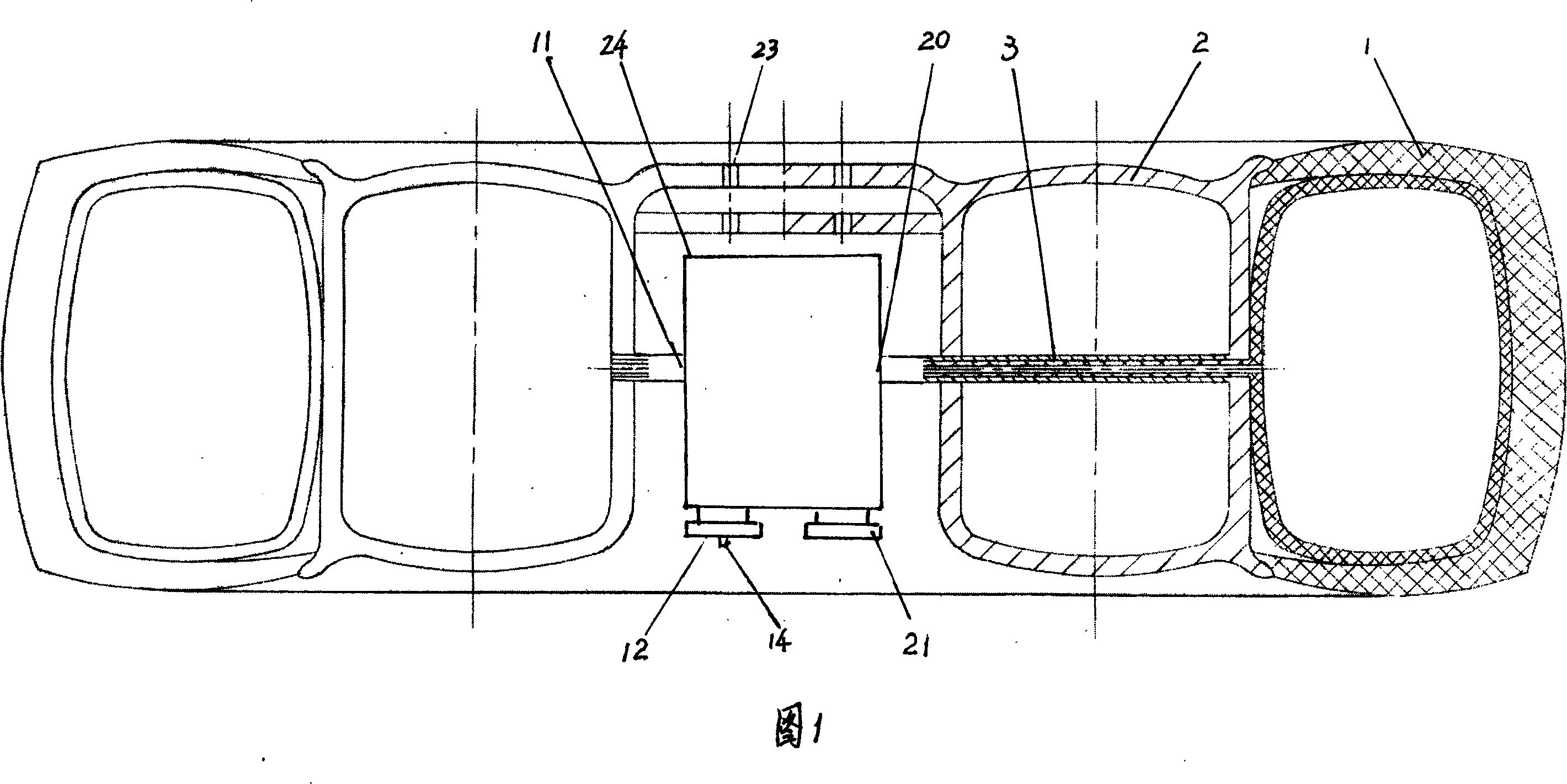

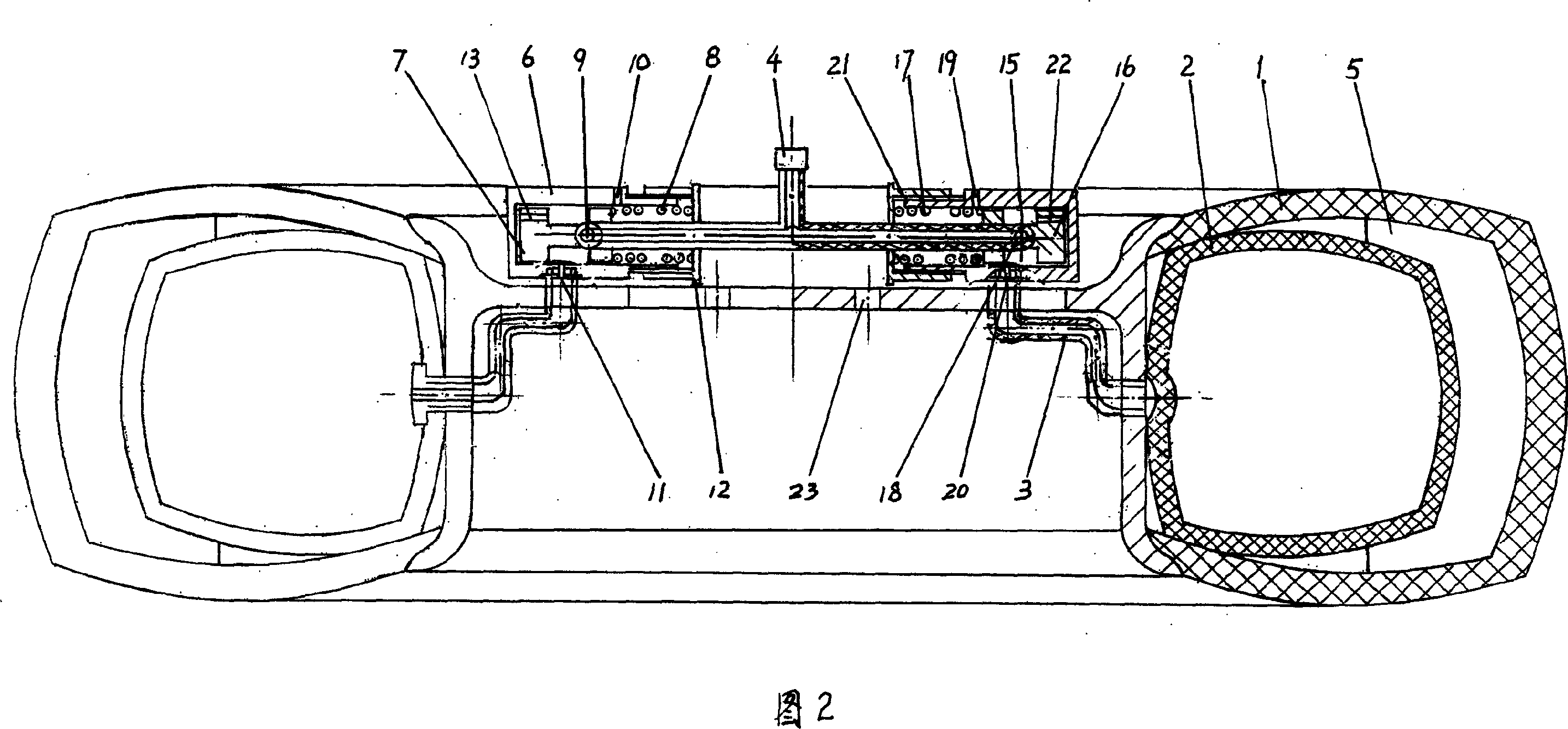

[0019] In Fig. 1, namely embodiment 1: the tire 1 is a tire with an inner tube, the high-pressure air bag 2 is close to the inner circle of the tire 1, and is fixed on the side of the tire 1, and the high-pressure valve and the low-pressure valve are a parallel integrated valve body, fixed At the center of the high-pressure air bag 2, the tire main shaft coupling port 23 is connected with the wheel main shaft.

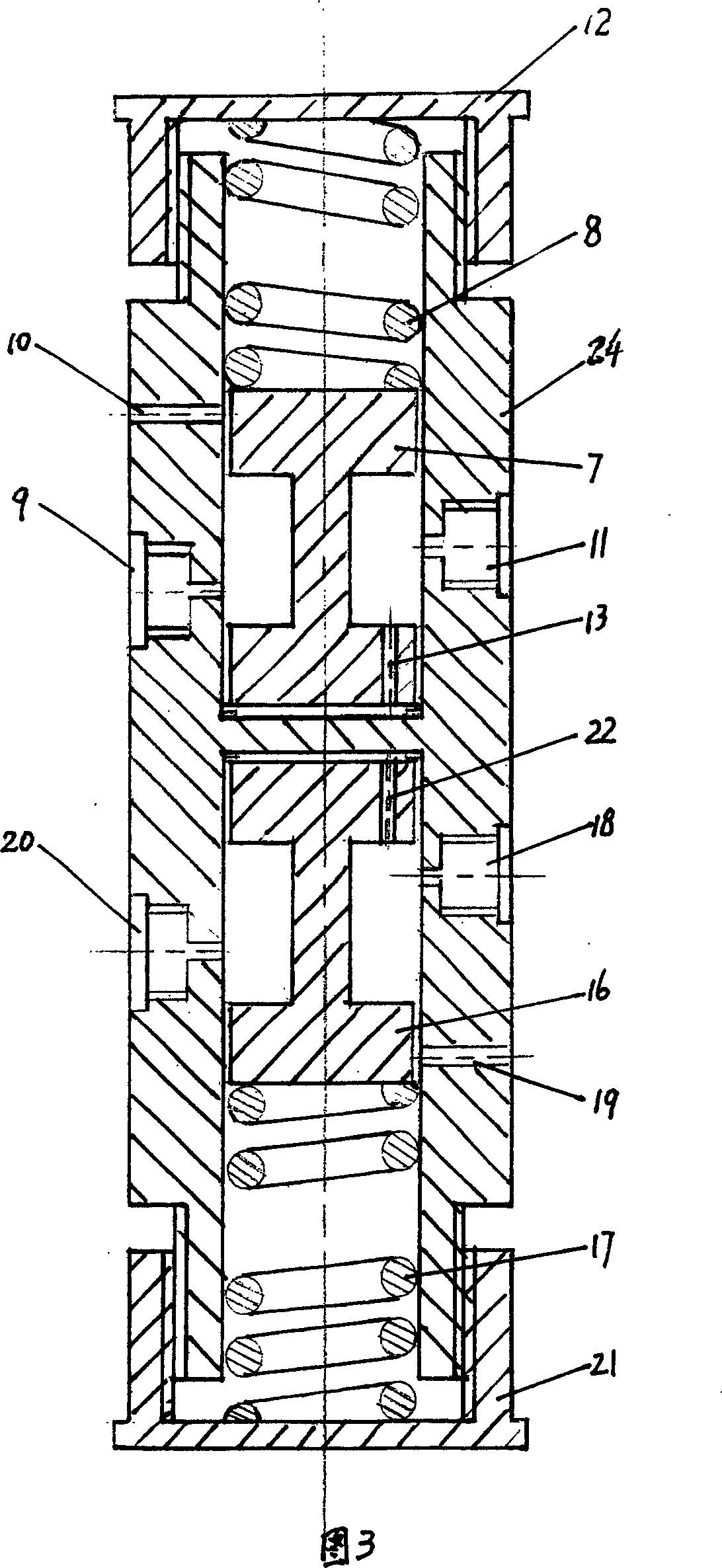

[0020] In Fig. 4, the left side is a high-pressure valve, the right side is a low-pressure valve, there are air inlet 9, exhaust hole 10 and Unicom hole 11 on the left side of the valve body 24, and the air inlet 9 passes through the pipeline and the right low-pressure valve. Connected, and connected with the intake pipe 4, the exhaust hole 10 is connected with the atmosphere, a whistle is installed in the hole, the Unicom hole 11 communicates with the high-pressure air bag 2 through the pipeline, the valve cover 12 is a pressure regulating nut, and the piston is held b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com