Waste and old tire cracking device and cracking method thereof

A waste tire and pyrolysis device technology, which is applied in the field of waste tire pyrolysis device, can solve the problems of low production efficiency, reduction of conveying devices, and long pyrolysis cycle, and achieve the effects of improving sulfur emission, increasing pyrolysis reaction rate, and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

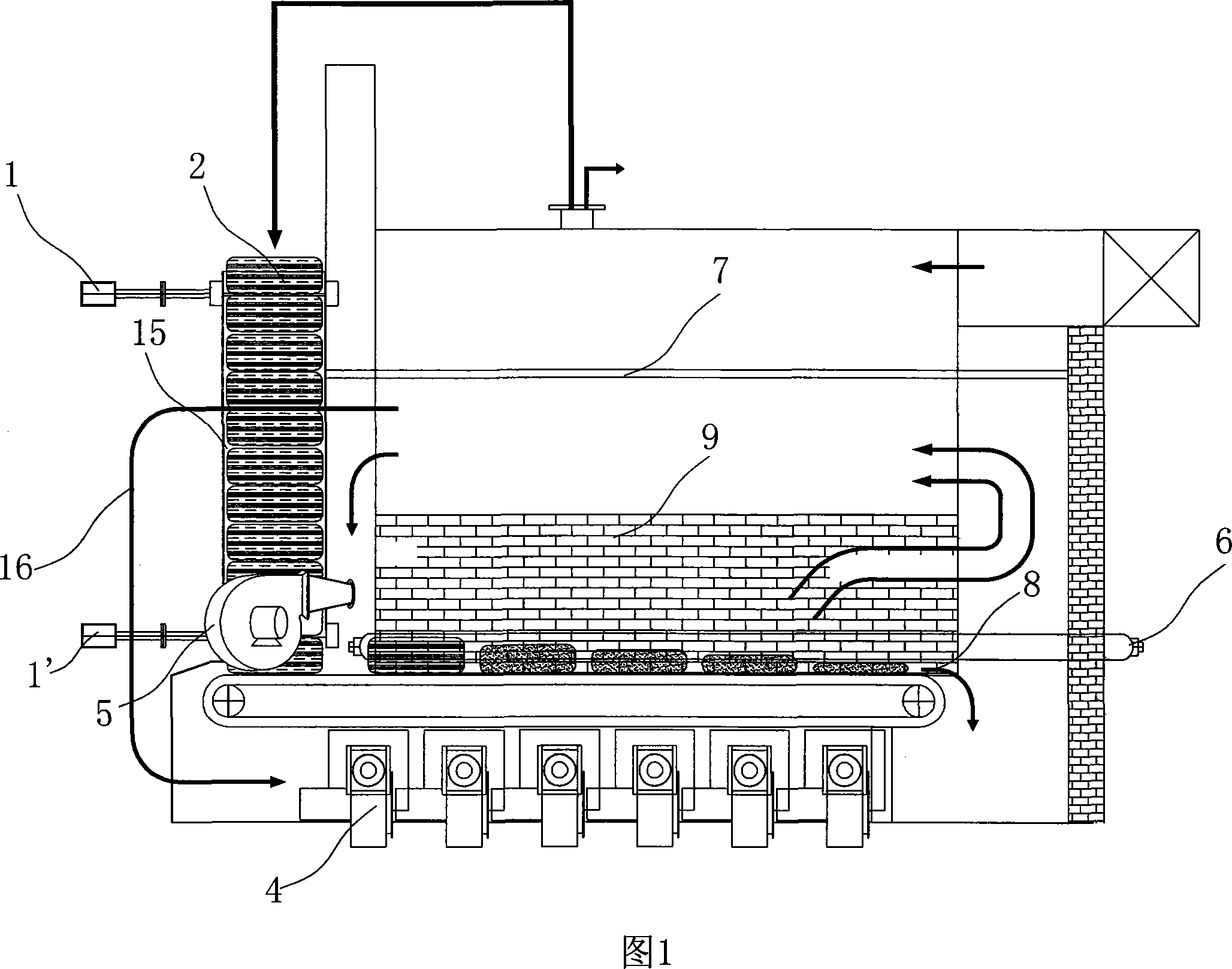

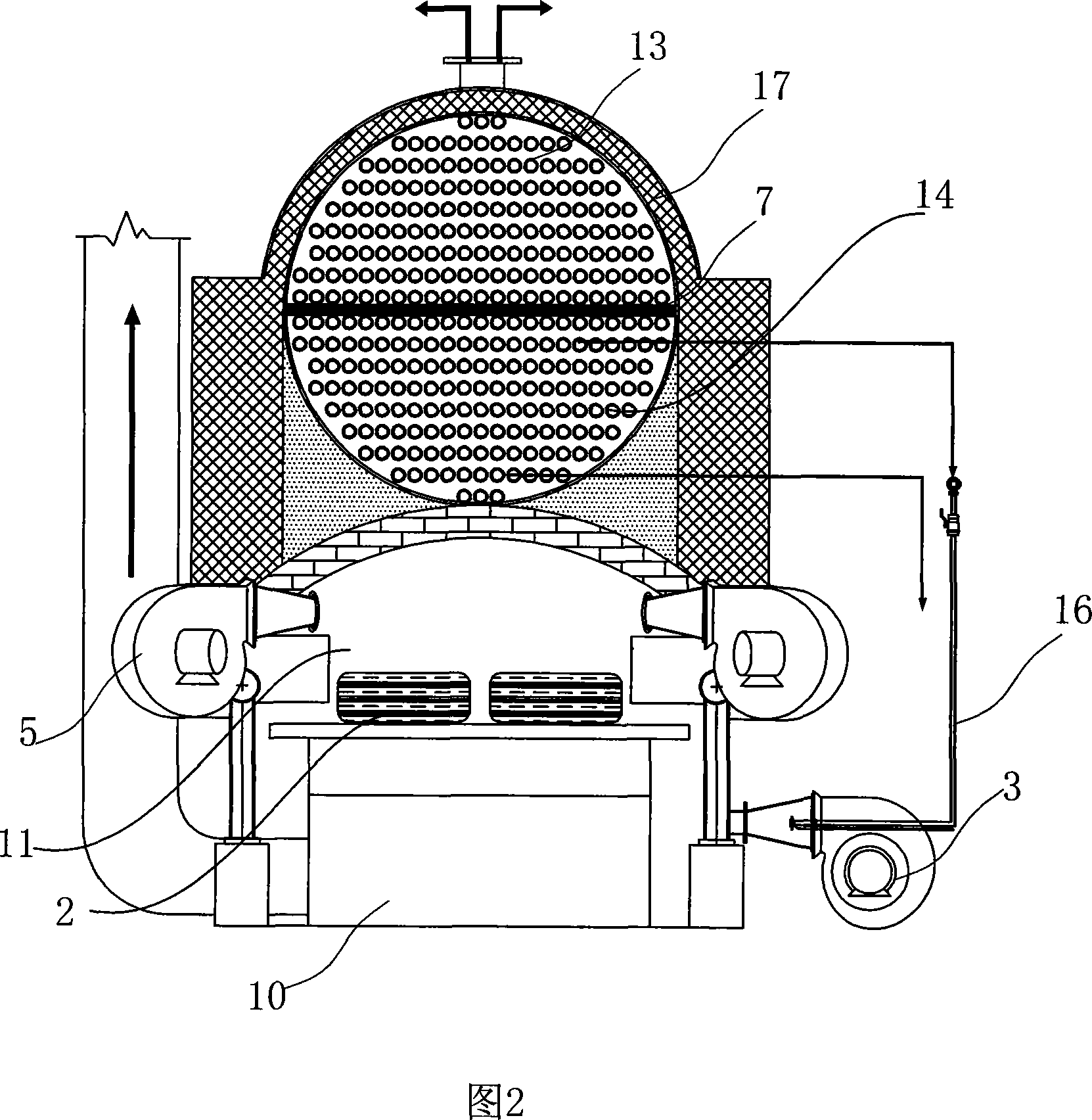

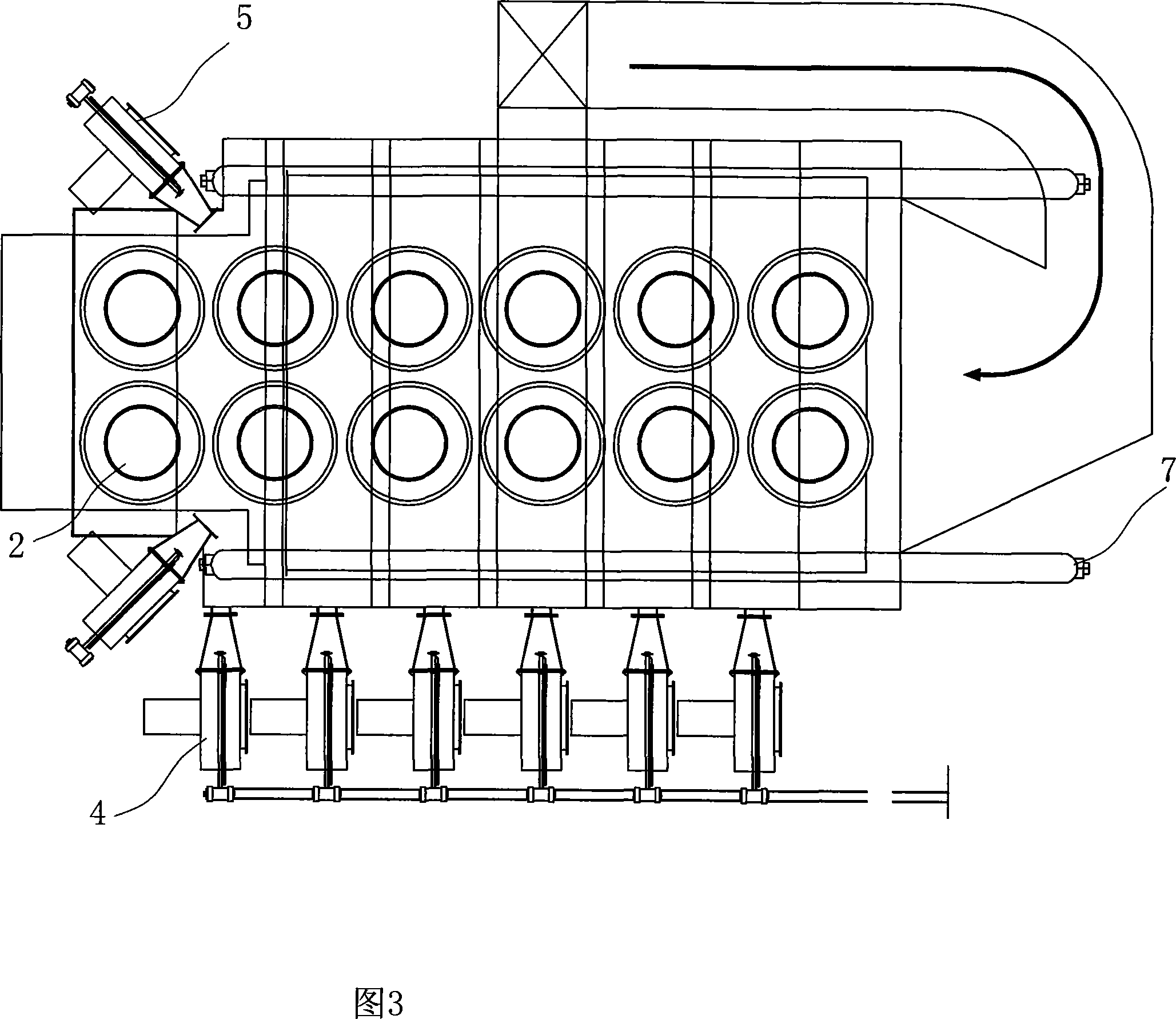

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0042] As shown in Figures 1 to 3, the waste tire pyrolysis device includes an airlock chamber 15 located at the front, and upper and lower ends of the airlock chamber 15 are respectively equipped with an upper sliding door 1 and a lower sliding door 1 for blocking air. ', the bottom of the airlock chamber 15 is positioned at the front end of the moving bed 8 to facilitate the loading of tires 2 to be processed; the moving bed 8 is connected to a variable speed motor (not shown); the combustion chamber 10 at the bottom and the The high-temperature cracking chamber 11 in the middle part of the waste tire pyrolysis device has an internal size of 12 feet and a width of 3 feet; the high-temperature cracking chamber 11 and the combustion chamber 10 are lined with refractory material 9, and the steel plate 6 is used as a separation plate to separate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com