Optical detecting method for internal surface of hole

A technology for the inner surface of a hole and optical detection, which is applied in the direction of material analysis, measuring devices, scientific instruments, etc. through optical means, to achieve the effect of large-scale rapid detection, fast detection speed, and small conditional restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

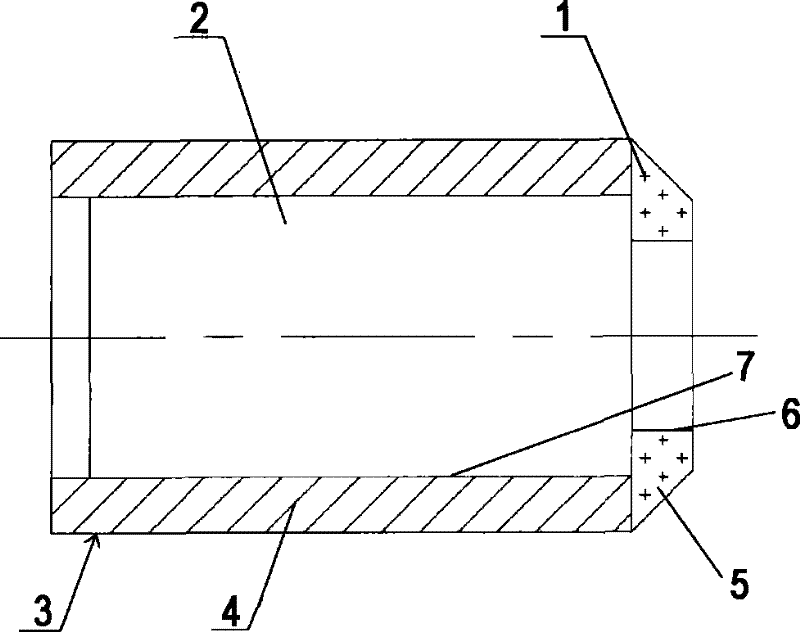

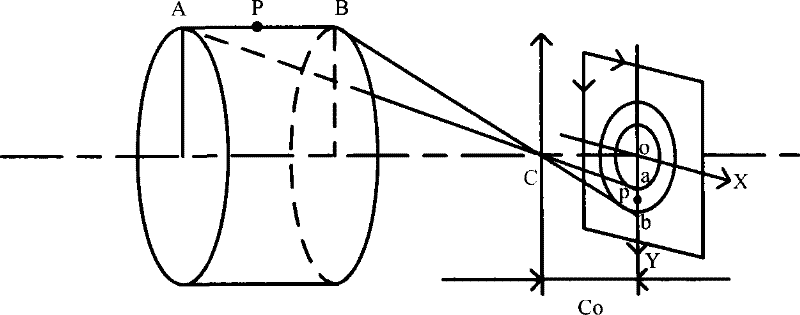

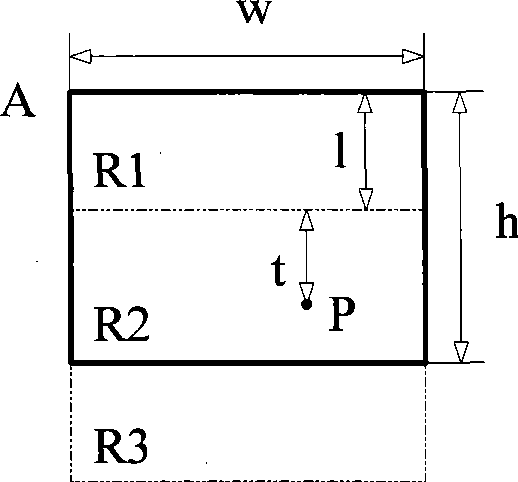

[0050] Following the steps described above, the figure 1 The optical sensor shown detects the inner surface of a hole. In order to verify the effectiveness of the algorithm, a special pattern is pasted on the inner surface of the hole. The servo motor drives the sensor to move at a constant speed along the axis of the hole. The computer gives a trigger signal to control the sensor to sample evenly. , first perform image back-projection transformation according to equations (1)-(3) to obtain a 360-degree expanded image of the inner surface, Figure 4 The upper middle picture is the original image of the inner surface of the hole sampled by the optical sensor. The annular area between the two circles C1 and C2 in the picture is the effective area of image processing. The center and radius of the two circles are set during the operation. Figure 4 The middle and lower images are the expanded image of the inner surface of the hole obtained after reprojection of the effective are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com