Device for treating flat fragile substrate

A substrate and flat technology, which is applied in the field of devices for processing flat and fragile substrates, can solve the problems of complex configuration of the opposing holding device and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

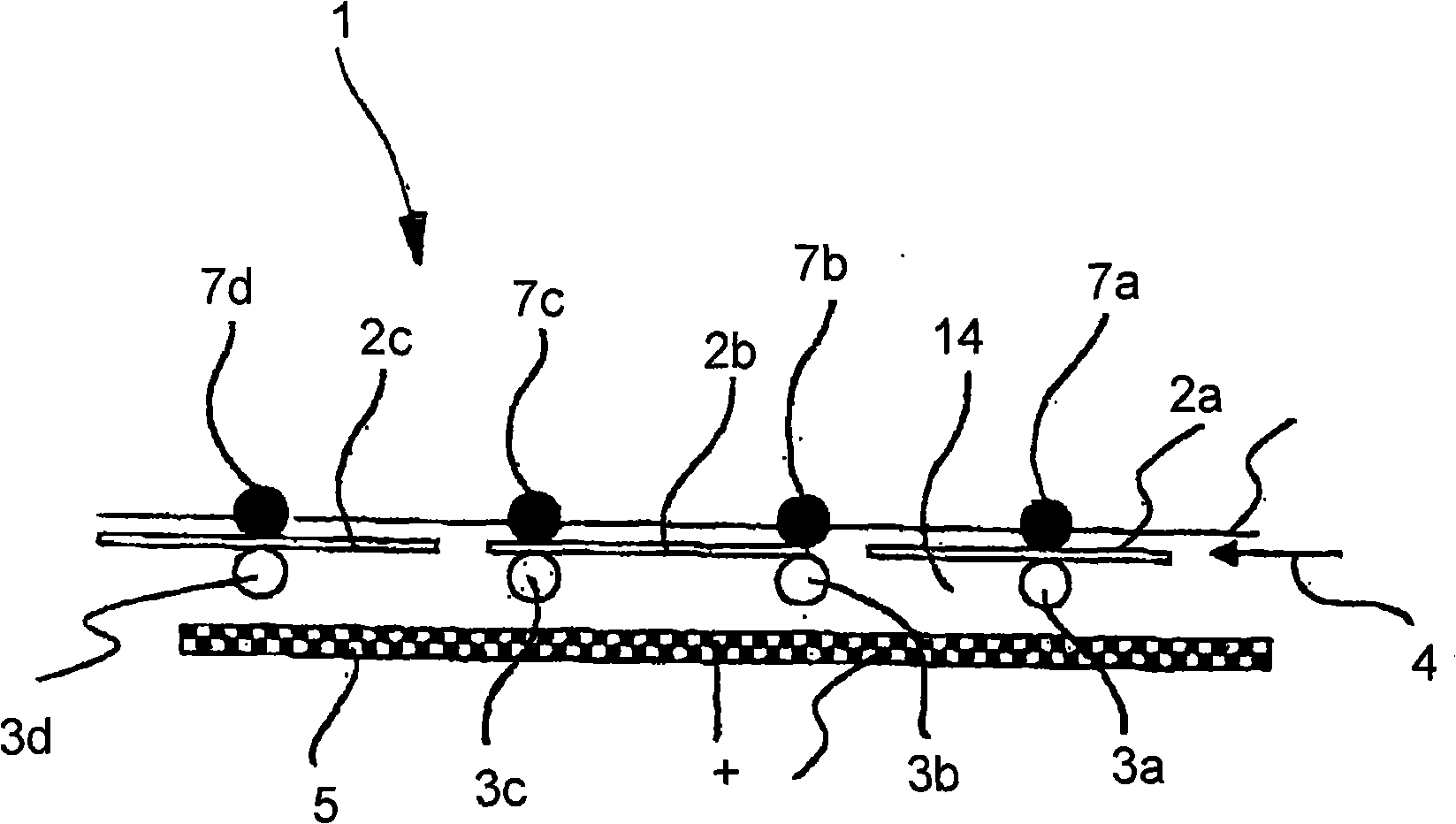

[0025] As an example of "processing" in the sense of interest here, an application from the solar industry is illustrated below:

[0026] For the production of solar cells, silicon plates with a thickness of approximately 0.2 mm are used which have vapor-deposited or screen-printed thin metallic conductor strips (Leiterzug) on the later "solar active" side . The conductor tracks must be reinforced / thickened by electroplating to a layer thickness of 1 to 20 μm. The strengthening material can be copper, tin, silver or gold. On the opposite side of the base body are the contact surfaces required for this, for example in the form of contact strips and / or contact windows, which are electrically conductively connected to the vapor-deposited or screen-printed electrical conductor strips on the "solar active" side .

[0027] figure 1 A device is shown, designated generally by the reference numeral 1, with which such vapor-deposited conductor tracks on a silicon substrate can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com