Method for manufacturing semiconductor integrated circuit device

A technology of integrated circuits and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., and can solve problems such as adverse effects of photoelectric conversion of photodetectors and uneven incident efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

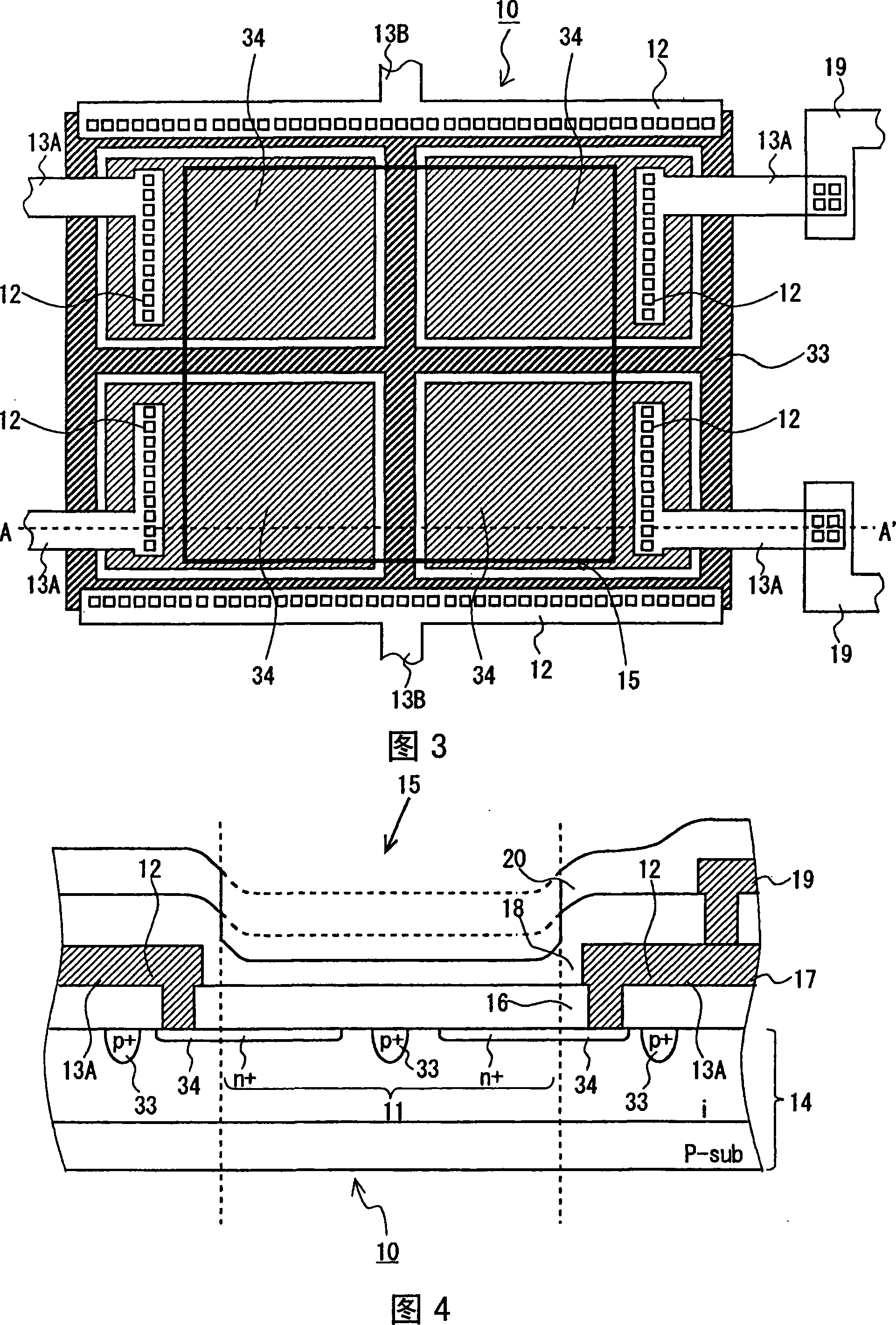

[0023] Embodiments of the present invention will be described below with reference to the drawings.

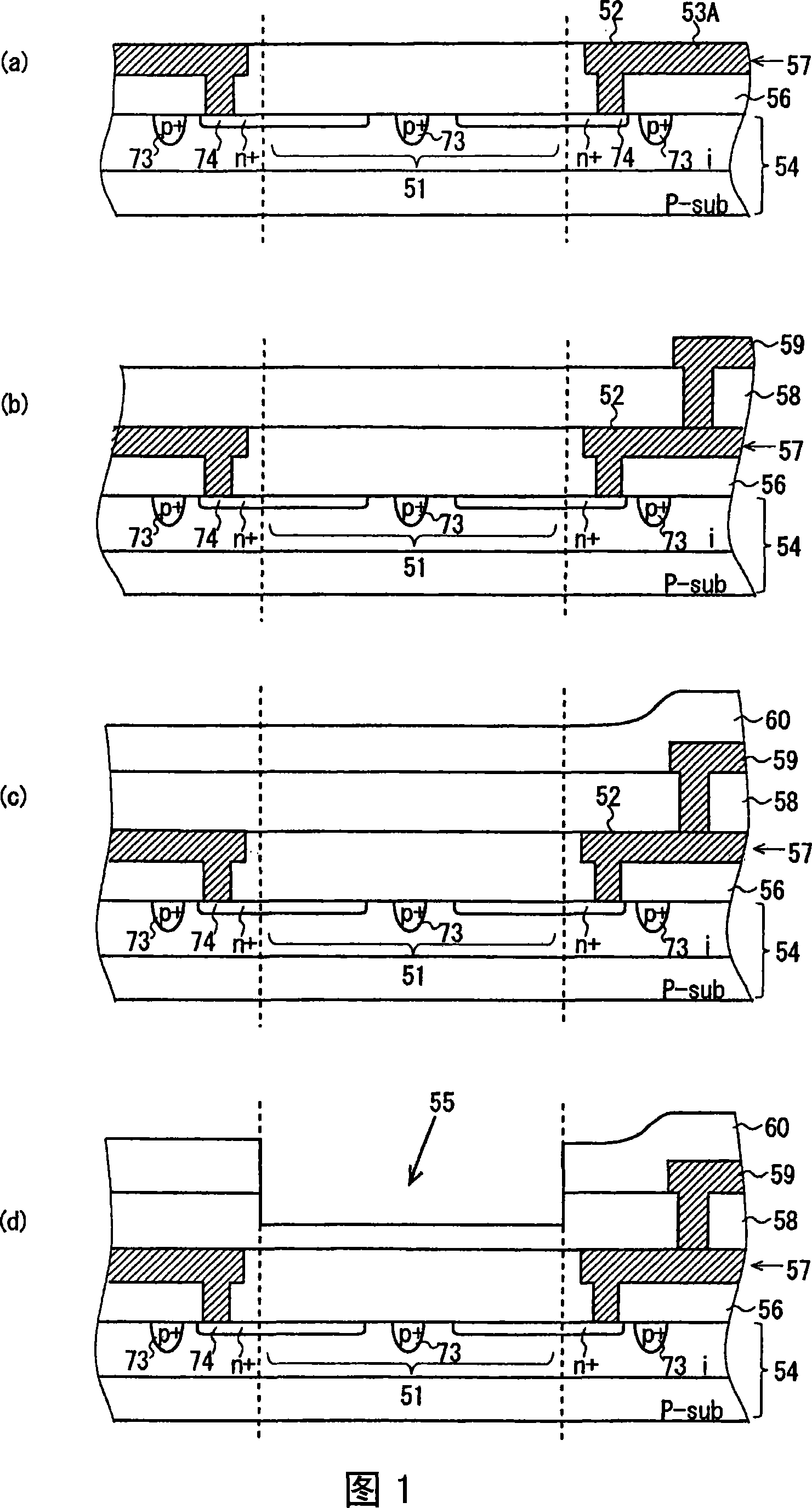

[0024] FIG. 1 is a diagram showing a photodetector formation process of Example 1. FIG.

[0025] Fig. 1 shows a section through the line A-A' shown in Fig. 3 and perpendicular to the semiconductor substrate. In addition, the planar shape of the photodetector in this embodiment is the same as that in FIG. 3 .

[0026] First, a first insulating film 56 is formed on a semiconductor substrate 54 on which a light receiving portion 51 has been formed, and a first metal layer 57 is formed by a damascene method ( FIG. 1( a )). The first metal layer 57 is formed of aluminum (Al), tungsten (W), or the like. The surfaces of the first insulating film 56 and the first metal layer 57 are formed flat by the damascene method, and the wiring structure 52, the signal line 53A connecting the wiring structure 52, and the voltage application line (not shown) are formed on the first metal layer 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com