A camera module of curved surface cmos image sensor

An image sensor and camera module technology, applied in image communication, instruments, televisions, etc., can solve the problems of poor image quality at the edge of the image, reduce the reflection of incident light, shorten the flange focal length, etc., to reduce the size, improve the overall performance, The effect of shortening the flange focal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

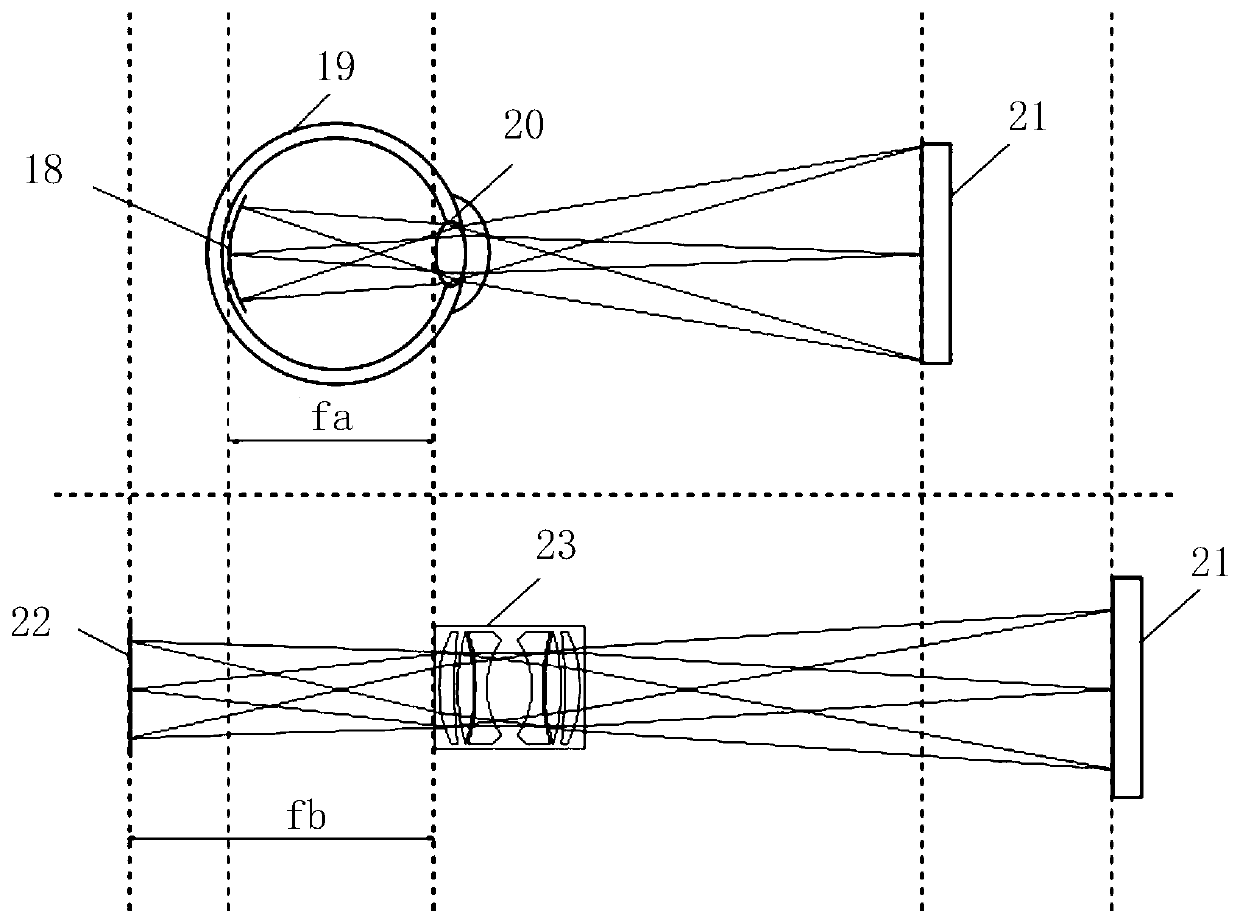

[0044] In this example, see Figure 5 , Figure 5 It is a schematic cross-sectional view of the camera module of the curved surface CMOS image sensor in Embodiment 1 of the present invention. Such as Figure 5 As shown, the curved surface CMOS image sensor camera module of the present invention includes two components of a coupled main lens 46 and a CMOS image sensor 35 . The main lens 46 is based on the double Gauss lens, but the spherical aberration correction lens is canceled. Therefore, the number of lenses is reduced by 3 compared to a typical double Gauss lens composed of 6 lenses, which includes a first convex lens 45 , a concave lens 44 , and a second convex lens 43 from top to bottom. Wherein, the first convex lens 45 and the second convex lens 43 are single-convex lenses, and their convex surfaces are set facing the outer direction of the main lens 46 group, and the concave lens 44 is a double-concave lens. After the main lens 46 cancels the spherical aberration ...

Embodiment 2

[0054] In this example, see Figure 6 , Figure 6 It is a schematic cross-sectional view of the camera module of the curved surface CMOS image sensor in the second embodiment of the present invention. Such as Figure 6 As shown, the curved surface CMOS image sensor camera module of the present invention includes two components of a coupled main lens 46 and a CMOS image sensor 49 . The design of the main lens 46 is exactly the same as that of Embodiment 1 (therefore, the same numerals are used), and it is also based on a double Gauss lens, but the spherical aberration correction lens is canceled, and the number of lenses is also 3. The main lens 46 sequentially includes a first convex lens 45 , a concave lens 44 , and a second convex lens 43 from top to bottom. Wherein, the first convex lens 45 and the second convex lens 43 are single-convex lenses, and their convex surfaces are set facing the outer direction of the main lens 46 group, and the concave lens 44 is a double-con...

Embodiment 3

[0063] In this example, see Figure 7 , Figure 7 It is a schematic cross-sectional view of the camera module of the curved surface CMOS image sensor in the third embodiment of the present invention. Such as Figure 7 As shown, this embodiment is another implementation manner of the first embodiment. The difference between this embodiment and Embodiment 1 is that the surface of the concave curved surface 40 of the metal layer 47 of the sensor 35 has the same curvature as the convex surface of the second convex lens 43 of the main lens 46, namely The shape of the concave curved surface 40 completely matches the convex shape of the second convex lens 43 of the main lens 46 . Therefore, the concave curved surface 40 and the second convex lens 43 are closely coupled, and there is no gap at all. That is to say, at this moment, the flange focal length of the main lens 46 is zero. Correspondingly, the upper end of the optical fiber 39 is no longer exposed, but is indented into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com