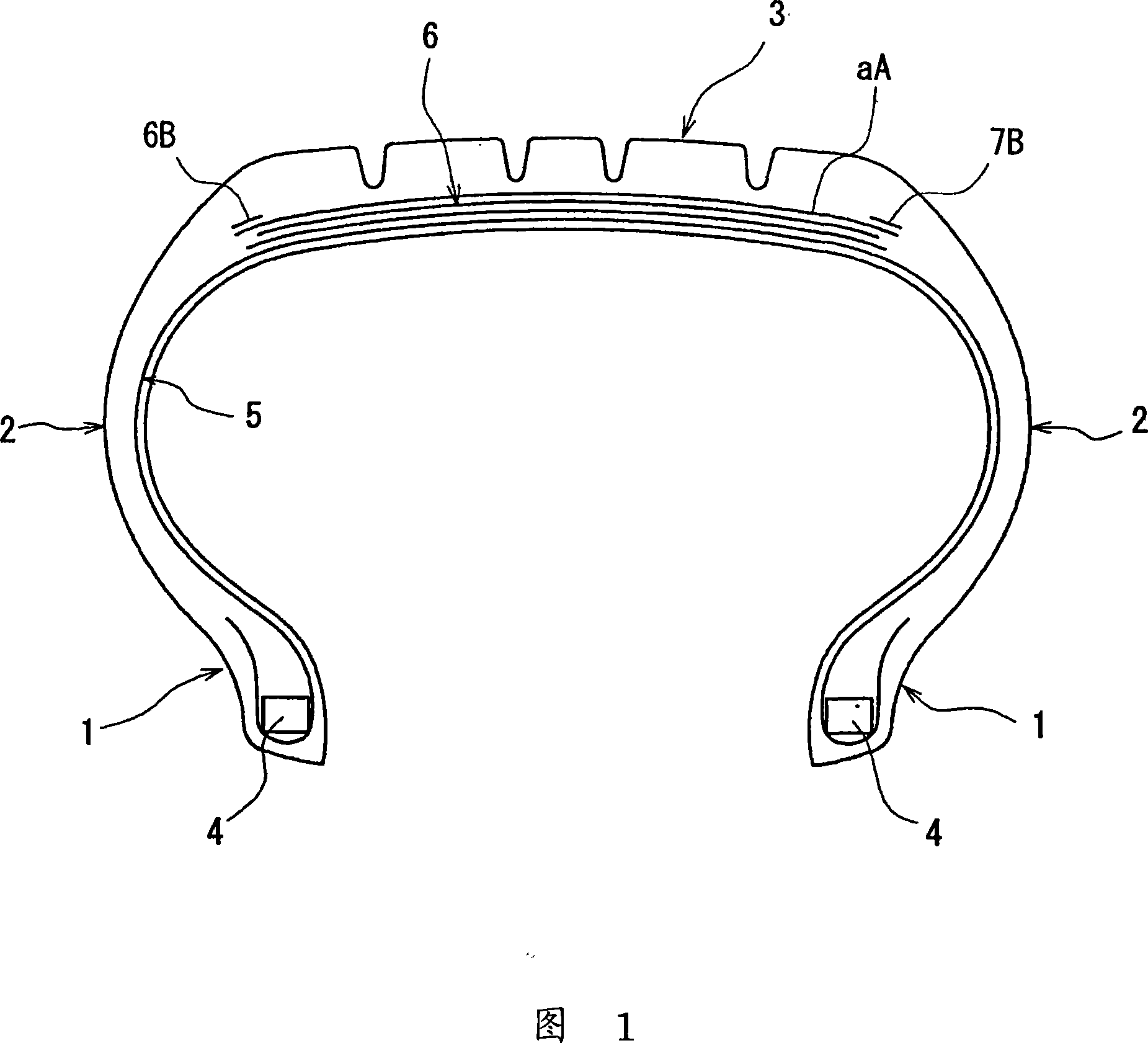

Pneumatic radial tire for car

一种子午线轮胎、乘用车的技术,应用在充气轮胎的增强层、车轮、轮胎零部件等方向,达到抑制突出和软化现象、提高操纵稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

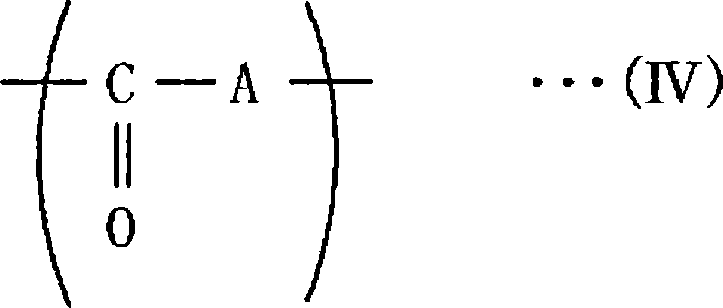

Method used

Image

Examples

Embodiment

[0068] The following examples are given to illustrate the present invention, and the present invention is not limited by the examples.

[0069] A pneumatic radial tire for passenger vehicles (tire size: 195 / 65R15) was prepared by using a carcass ply of the material, structure and properties shown in Table 1.

[0070] (Stability during actual operation at high speed)

[0071] The performances of the pneumatic radial tires for passenger vehicles in Examples 1-3 and Comparative Examples 1-2 were evaluated. This test was conducted by running the vehicle on a test course with one lap of 4 km to evaluate four performances including straight-line running stability, steering stability, feeling of rigidity, and handling performance. Each test result was evaluated using a 10-point method, where the larger the value, the better the performance. Table 1 shows the results.

[0072] Table 1

[0073] Comparative example 1

Comparative example 2

Example 1

Example 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| logarithmic viscosity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com