Sealing device

A technology for sealing devices and sealing elements, which is applied to the sealing of engines, non-mechanical drive clutches, fluid drive clutches, etc. It can solve problems such as large fitting installation force, deformation of core 104, and increased output power, so as to improve resistance , the effect of preventing detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. However, the scope of the present invention is not limited to the specific description, nor is it limited to the contents described in these embodiments.

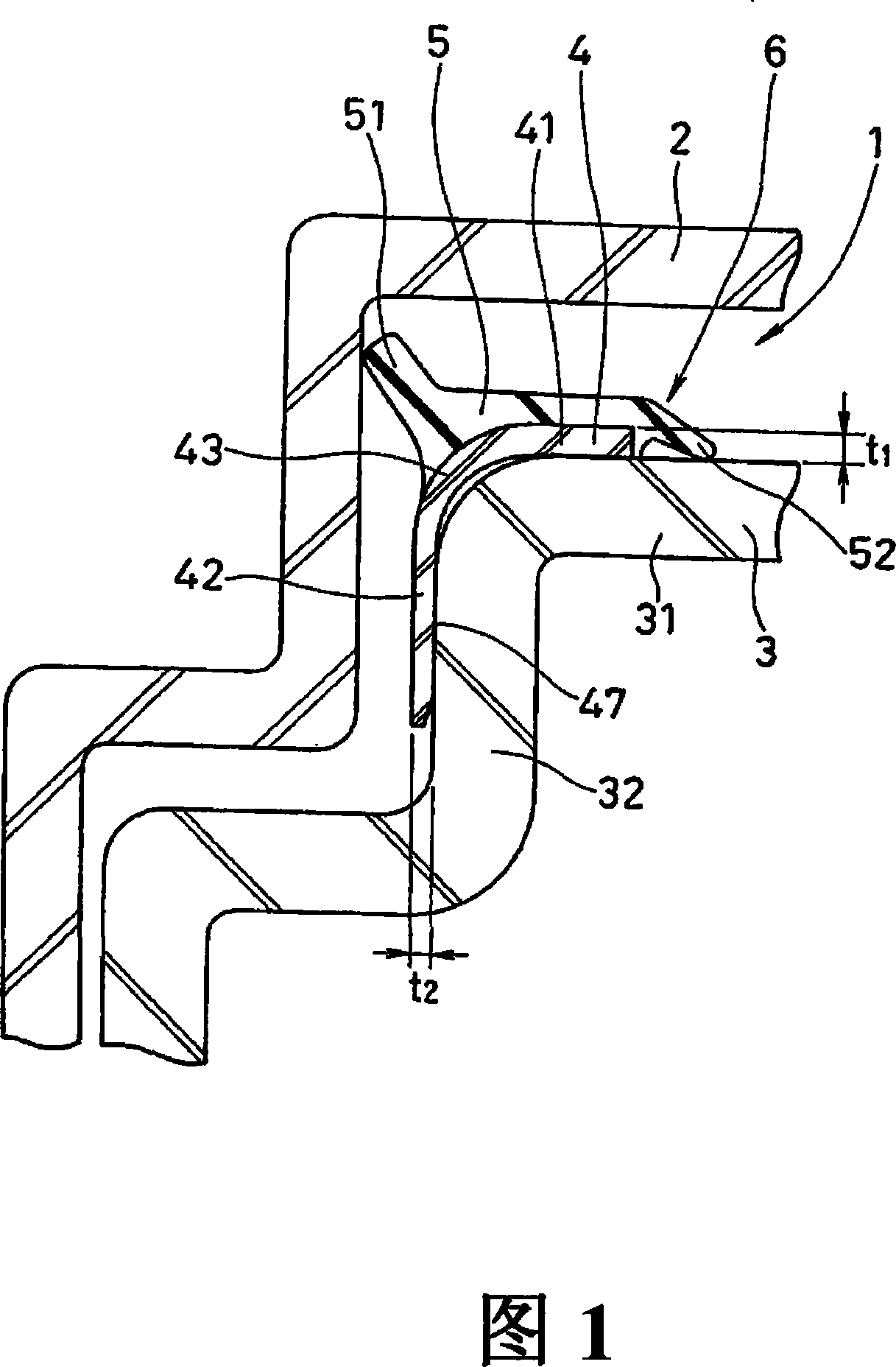

[0034] Fig. 1 is a sectional view of a main part of a sealing device according to an embodiment of the present invention to which a piston member capable of reciprocating axially in a cylinder is installed.

[0035] As shown in Figure 1, the sealing device 1 of the present invention is installed on the piston element 3 reciprocating in the axial direction in the bottomed cylindrical cylinder 2, and is used for sealing between the cylinder 2 and the piston element 3; by having a core 4 and the sealing element 6 of the sealing part 5.

[0036] The core 4 is a metal plate with an L-shaped cross-section, and is integrally formed by the following structure: the flange portion 31 located on the innermost diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com