Heating cooker and steam generating device for the same

A technology for a steam generating device and a cooker, which is applied to heating devices, steam cooking utensils, etc., can solve the problems of sanitation, accumulation of baffles, and ineffective use of steam, so as to achieve a large heating effect and eliminate waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

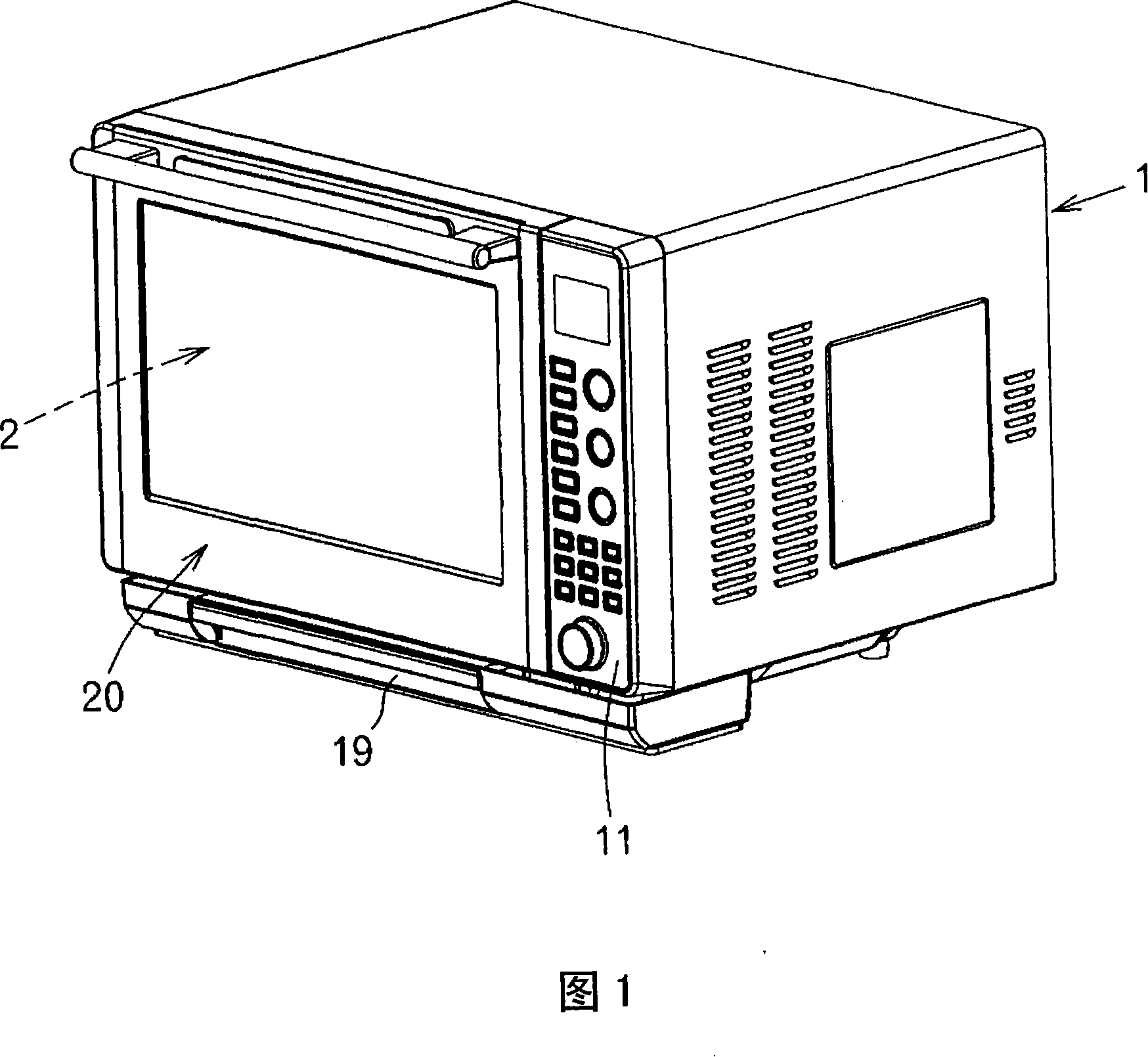

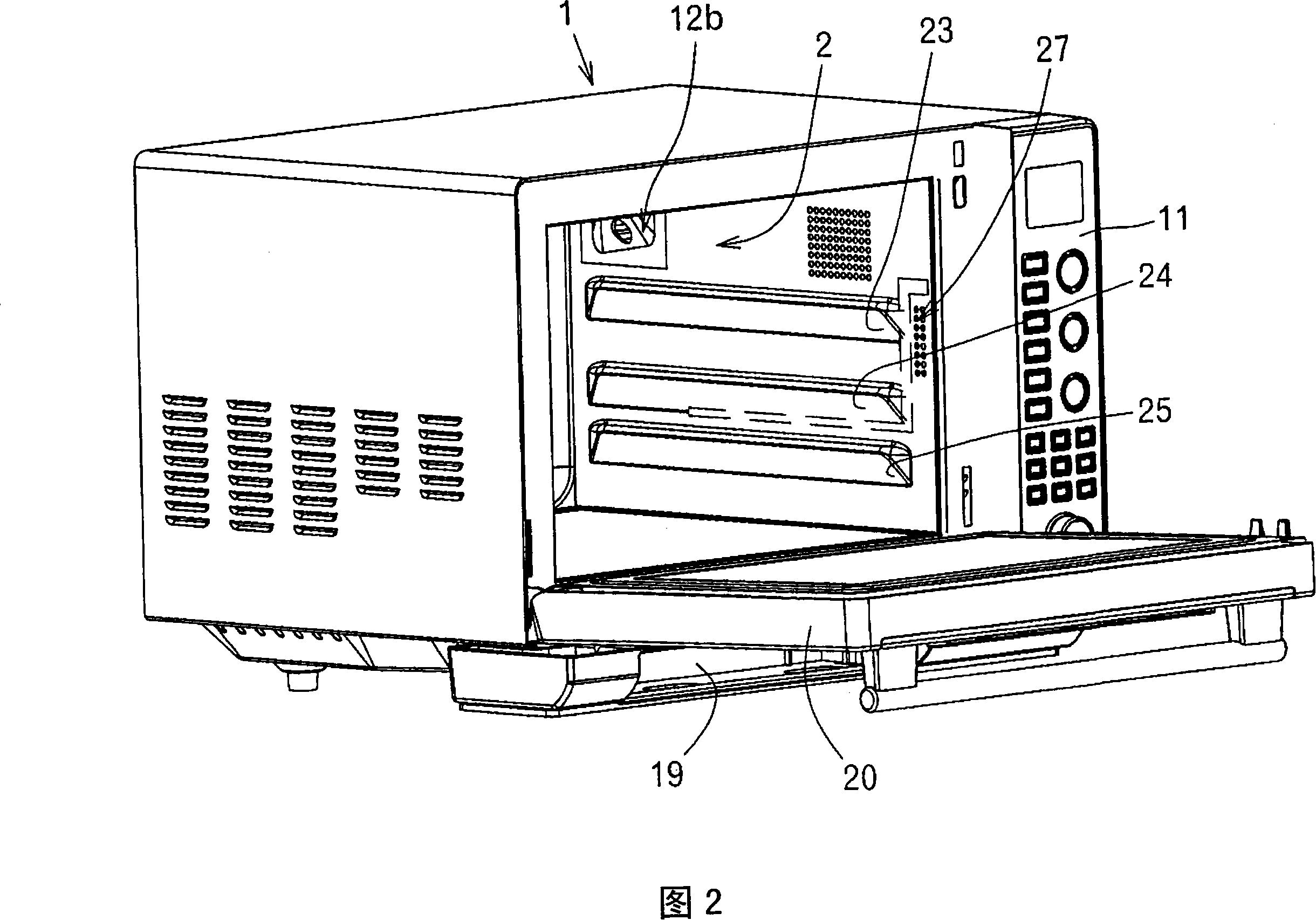

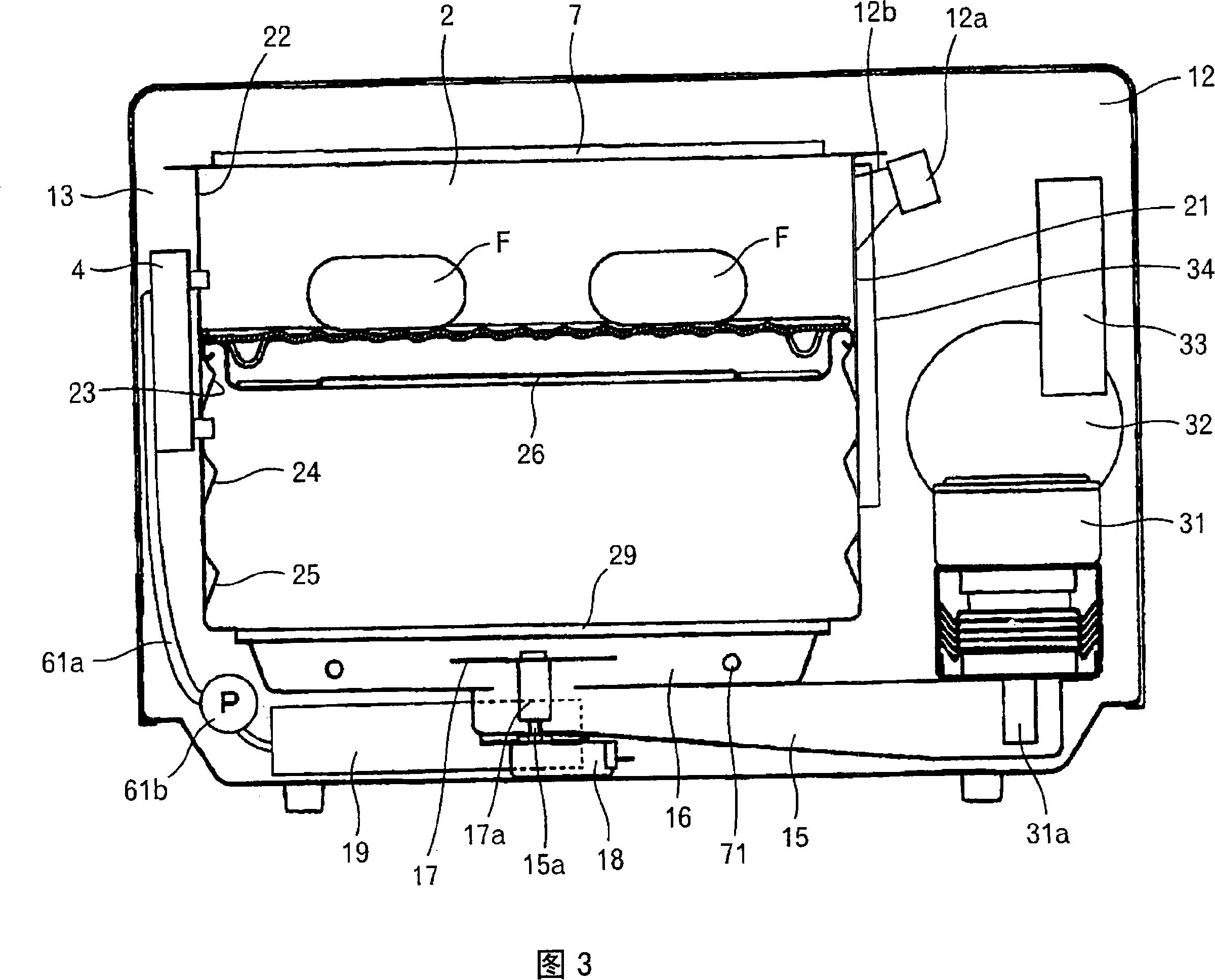

[0060] The schematic structure of the whole heating cooker is demonstrated based on FIGS. 1-5.

[0061] The heating cooker of the embodiment has a microwave heating cooking function and a heater heating cooking function in addition to the steam heating cooking function.

[0062] The front of the cooker body 1 is open, and a heating chamber 2 for accommodating foods to be heated and cooked is formed inside.

[0063] A door 20 is provided on the front opening of the cooking device main body 1 . The lower portion of the door 20 is pivotally supported to be rotatable.

[0064] An operation panel 11 is provided on the right side of the door, and on the operation panel 11, devices necessary for cooking operations such as an input key group 11a, a display unit 11b, and a start button 11c are provided.

[0065] The input key group 11a is used to select or set heating conditions, automatic cooking menus, and the like. The display unit 11b displays input heating conditions, remaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com