Bicycle labor saving driving wheel

A technology for bicycles and driving wheels, which is applied in the directions of rider driving, vehicle components, transportation and packaging, etc., which can solve problems such as unreachable, and achieve the effect of being easy to accept and compact in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

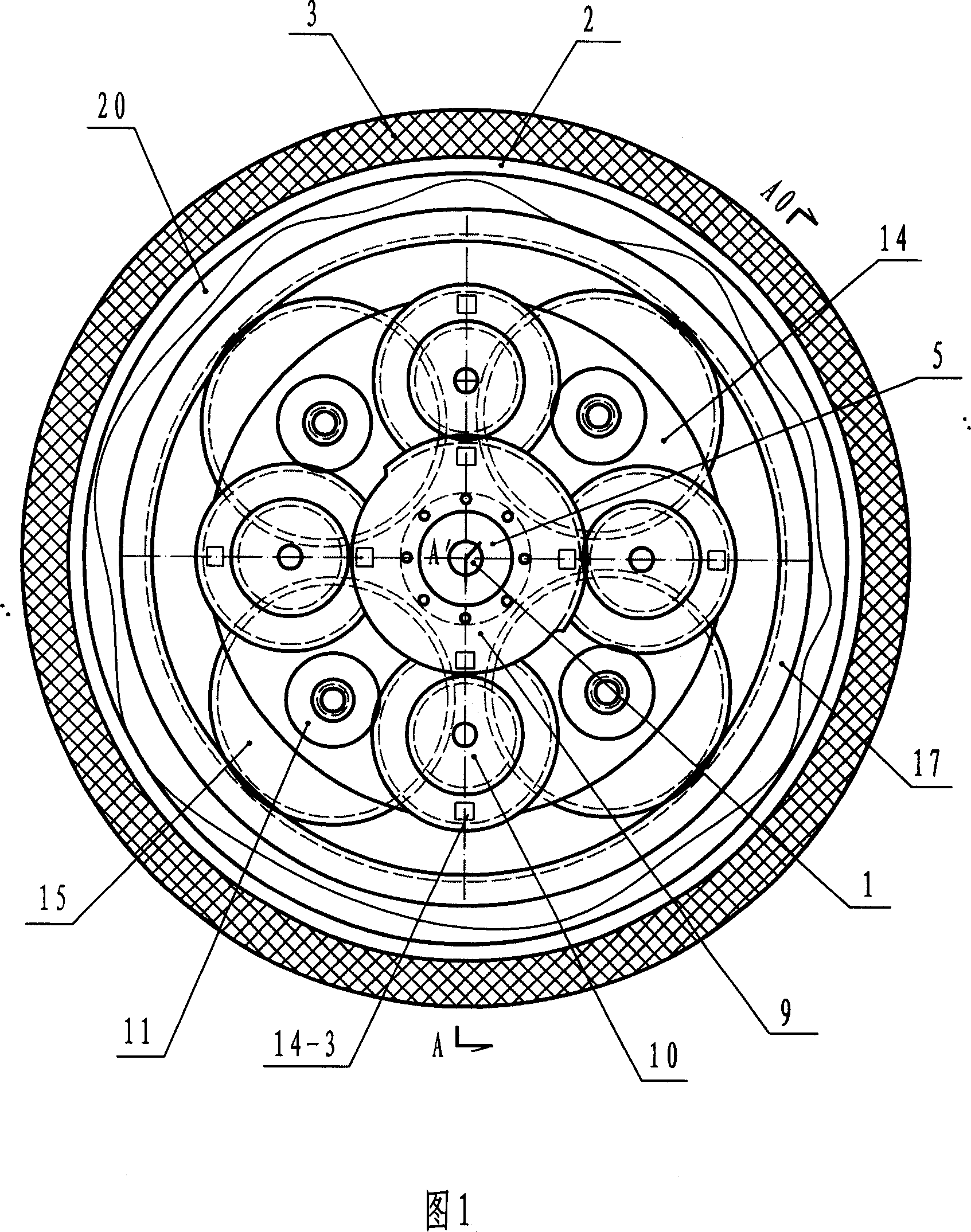

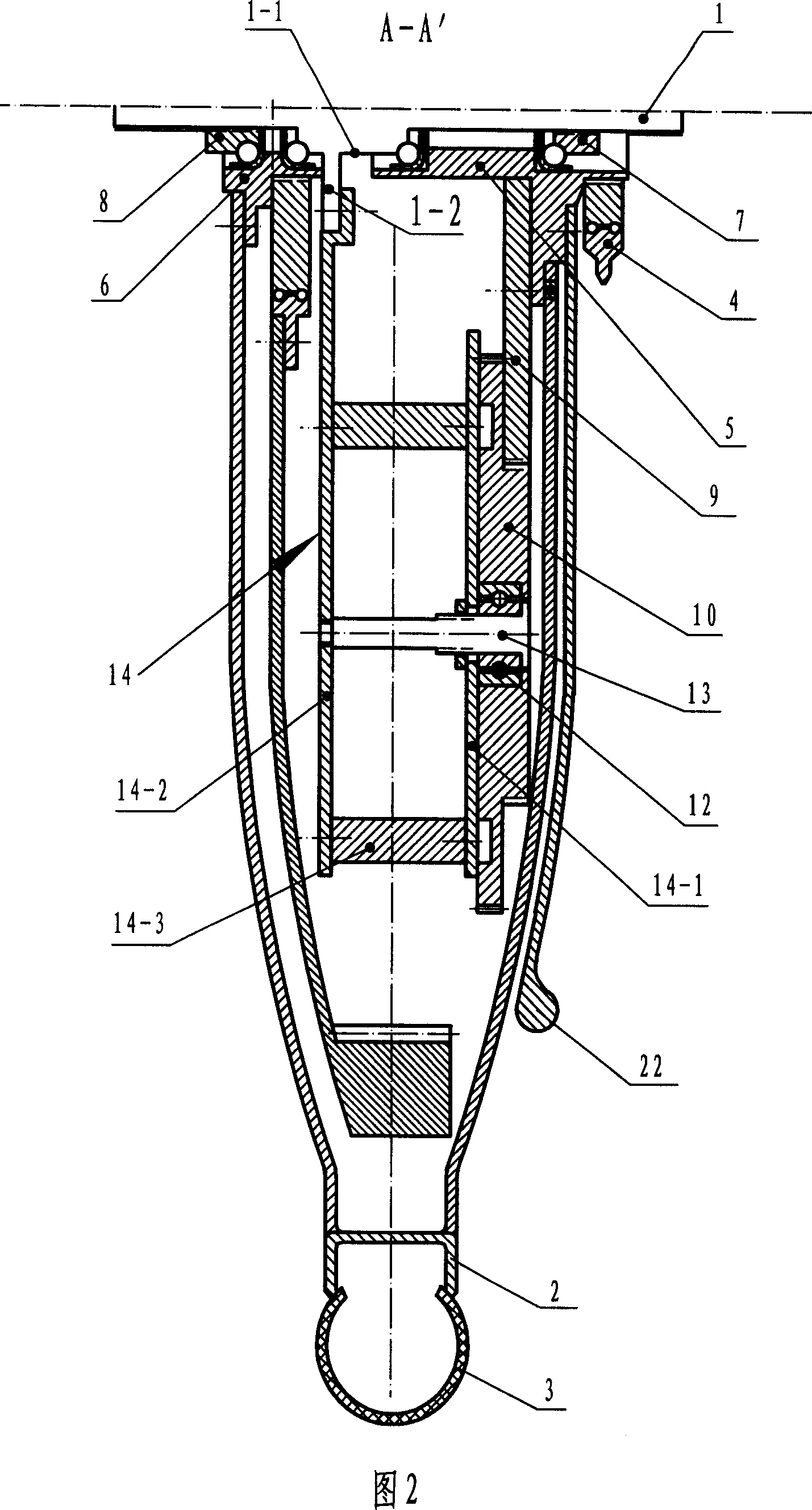

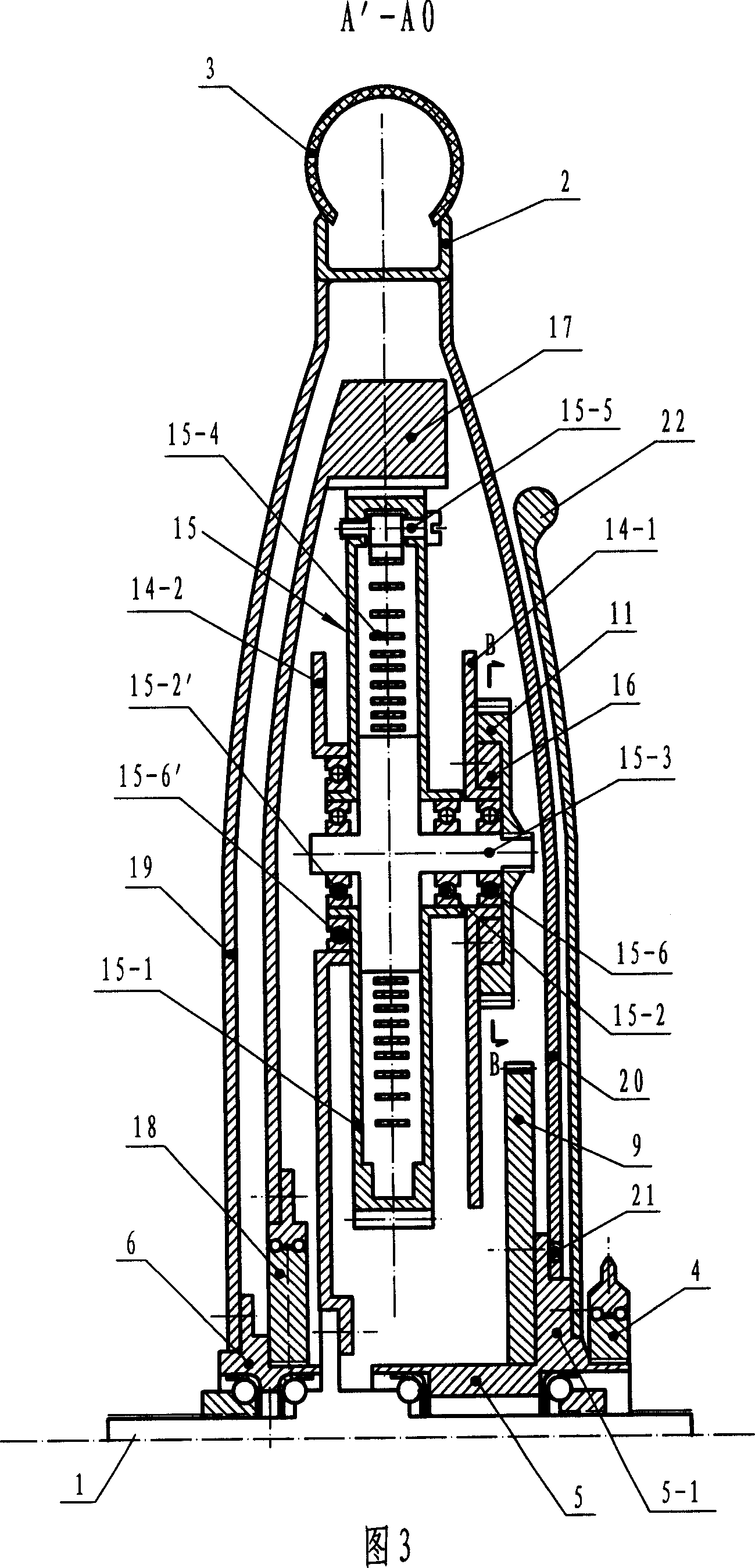

[0015] Referring to Fig. 1, 2, it comprises a bicycle rear wheel supporting shaft 1, rim 2, the tire 3 that is contained on the rim and a one-way overrunning clutch 4 (commonly known as rear flywheel) that links to each other with the faceplate on the center shaft by chain. ), the rear wheel support shaft 1 is covered with two left and right bead sleeves 5, 6, wherein the right bead sleeve 5 is used as the drive input shaft, and the left bead sleeve 6 is used as the drive output shaft, both of which can be wound around the rear wheel The support shaft 1 rotates, and the two ball sleeves are axially fixed by two nuts 7, 8 and the diameter-expanding section 1-1 located at the middle of the rear wheel support shaft 1; Connect the described one-way overrunning clutch 4, a driving gear 9 is fixedly connected at its left end, and the driving gear 9 is a half gear, and four evenly distributed intermediate gears 10 and four evenly distributed secondary gears are arranged around the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com