Substrate processing apparatus

A technology for processing equipment and equipment, applied in the direction of gaseous chemical plating, coating, electrical components, etc., capable of solving problems such as insulator 20 material and design limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Reference will now be made in detail to the preferred exemplary embodiments, examples of which are illustrated in the accompanying drawings.

[0031] The purpose of the present invention is to completely insulate the surfaces of different potentials in the substrate processing equipment, and does not limit the structure of the gas distribution plate and the plasma electrode. More precisely, the invention is directed to insulating two components having different potentials or two potential surfaces in a substrate processing apparatus or chamber. The present invention is not limited to the insulating member provided between the gas distribution plate and the electrodes as will be explained below.

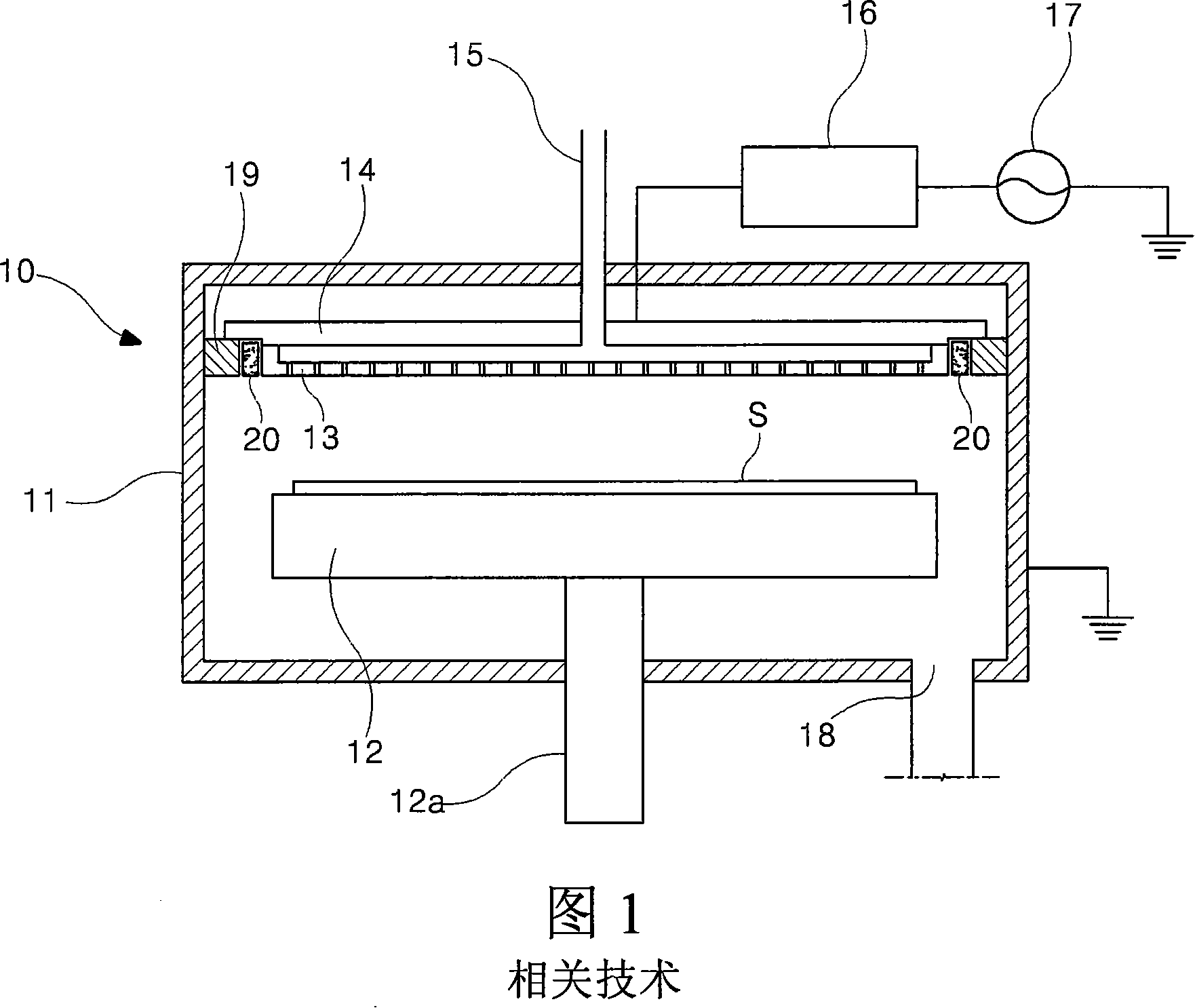

[0032] The substrate processing apparatus of the present invention may have a structure similar to that of FIG. 1 . Components that are the same as those in the related art may have the same references, and explanations for the same components may be omitted.

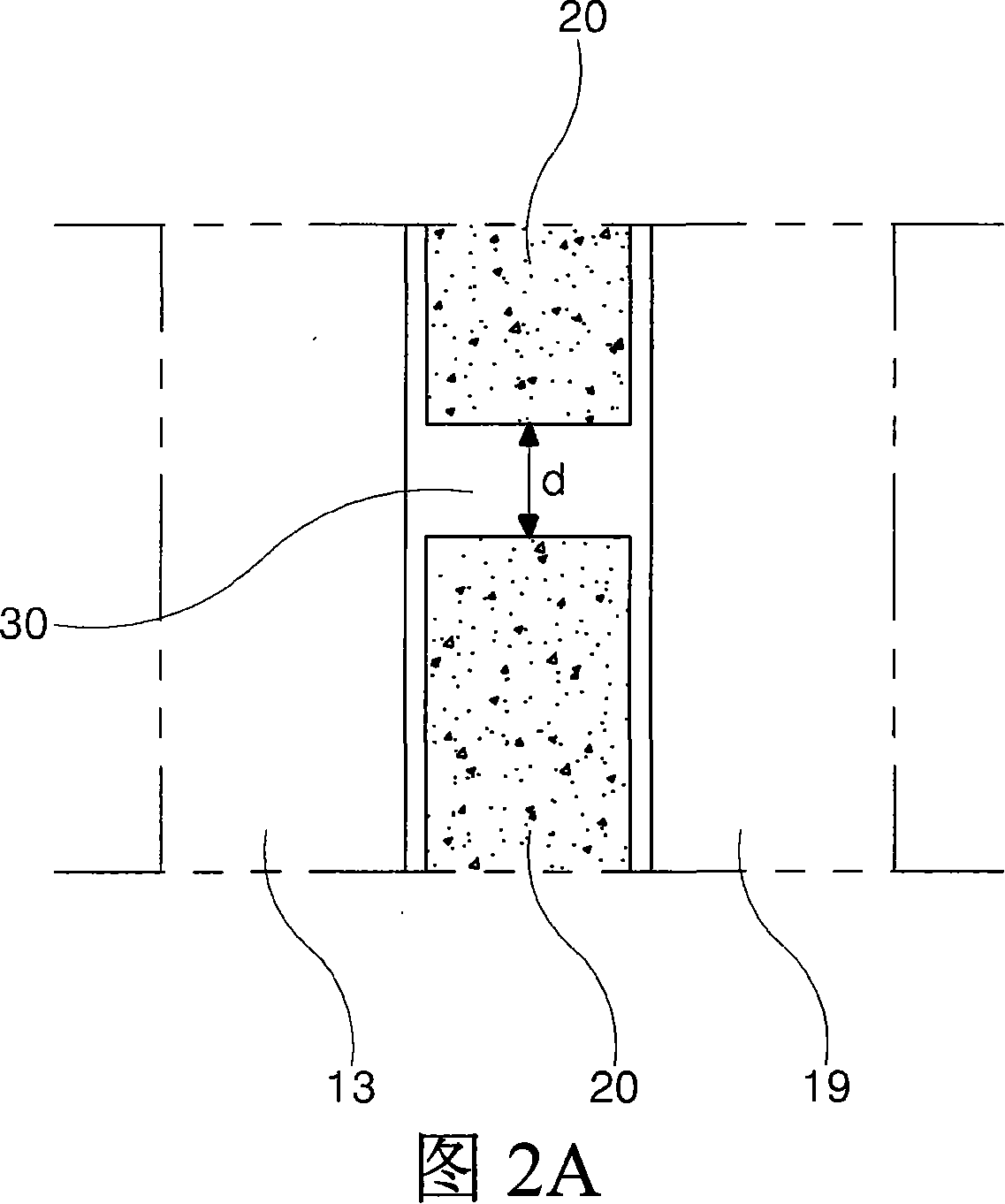

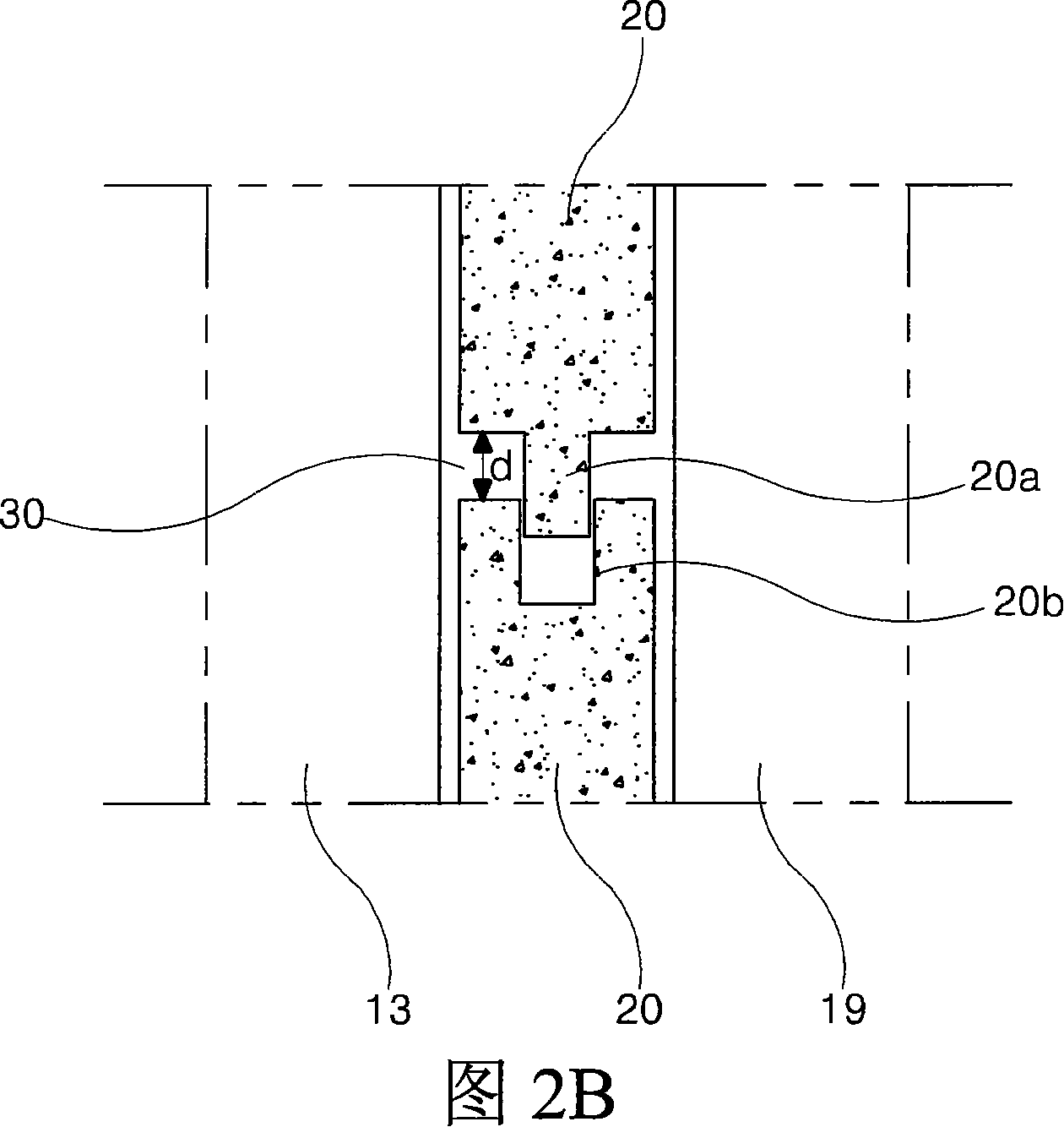

[0033] In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com