Elastica loading unit capable of simulating formation resistance capability

A technology for simulating strata and loading devices, which is applied in basic structure testing, construction, and basic structure engineering, etc., can solve problems such as inability to load, do not meet the interaction between stratum and soil, increase test cost and workload, and achieve convenience loaded effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

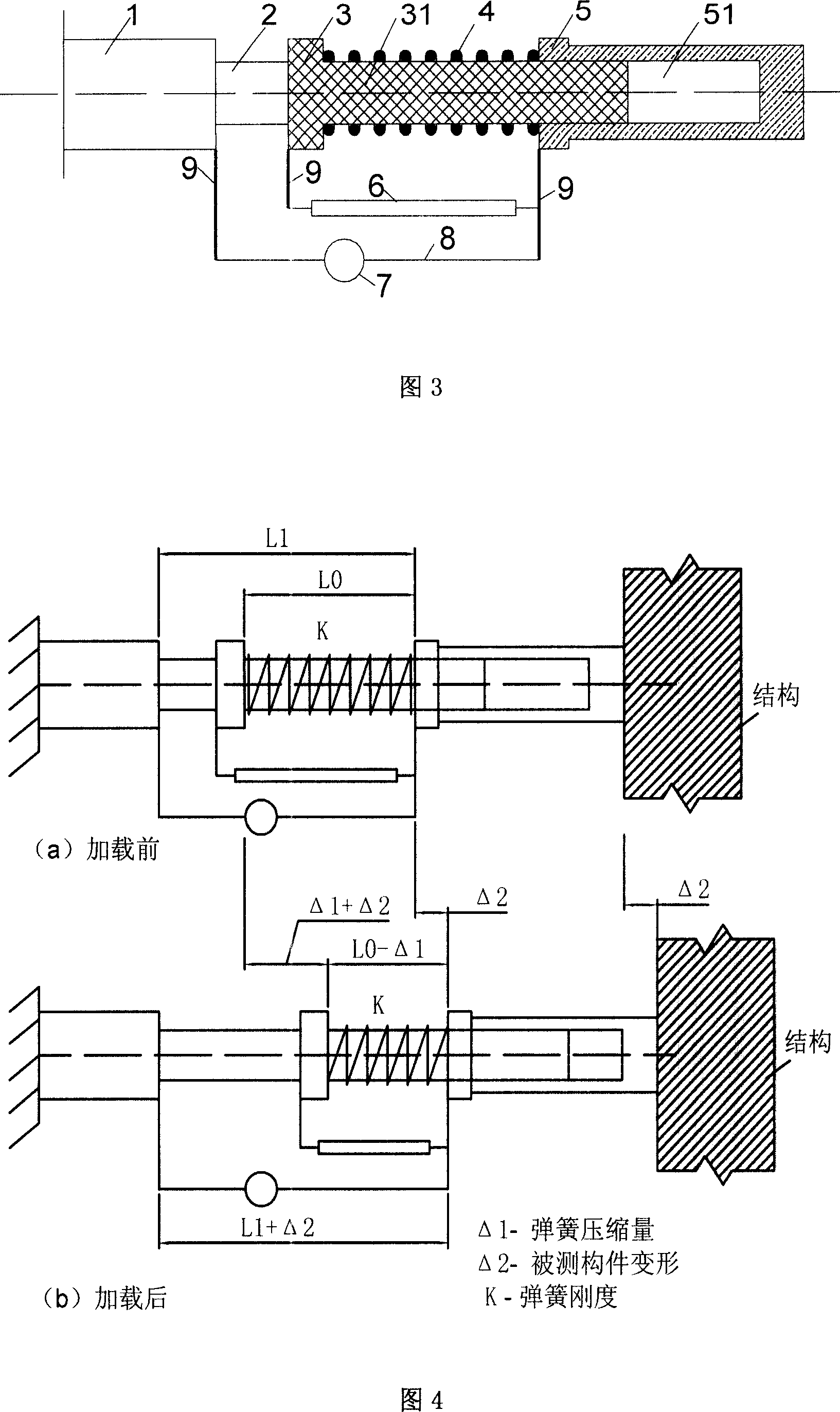

[0026] As shown in Figure 3, the elastic loading device of the present invention comprises a jack, is provided with fixed base 1 and loading head 2 on it, and elastic device is made of dowel bar 3, spring 4 and loading bar 5, and the rear of dowel bar 3 end is connected with the loading head 2, and the front end of the dowel bar 3 is connected with the loading bar 5 through the spring 4. In order to guide and facilitate the installation of the spring, the front end of the dowel bar 3 is fixedly connected to a section of the guide bar 31, and the center of the loading bar 5 A guide hole 51 is provided for sliding fit with the guide rod 31 , and the spring 4 is sleeved on the outside of the guide rod 31 and compressed between the dowel rod 3 and the loading rod 5 . A fixed frame 9 is respectively fixed on the fixed seat 1, the dowel bar 3 and the loading bar 5, wherein a scale indicator ruler 6 is connected between the two fixing frames 9 on the loading bar 5 and the dowel bar 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com