Comprehensive Loading Device for Reliability Test of CNC Cylindrical Grinding Machine

A technology of cylindrical grinder and loading device, which is applied in the direction of measuring device, machine/structural component test, instrument, etc., can solve the problems of less research on CNC cylindrical grinder, achieve wide braking range, simple control method, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

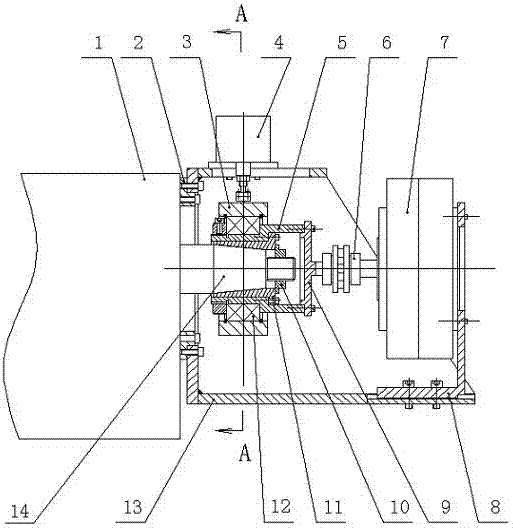

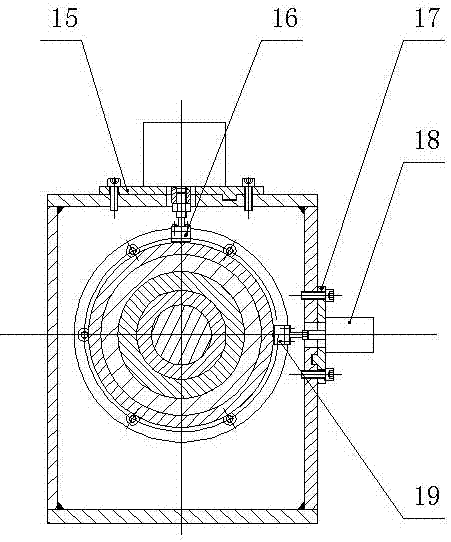

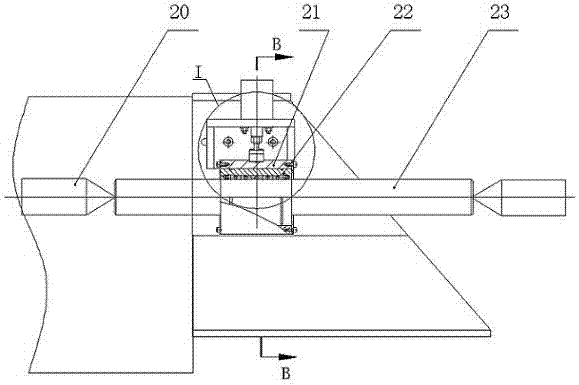

[0043] see Figure 1-8 , the present invention provides a comprehensive loading method for the reliability test of a CNC cylindrical grinding machine: the workpiece shaft is installed on the head frame of the grinding machine to simulate the workpiece to be ground, and the cylinders 4, 18, 25, 28 are used as force load application devices, The brake 7, 33 is used as the torque load applying device to simulate the stress state of the grinding wheel shaft of the grinding machine and the workpiece to be ground in the actual grinding process. Use the miniature load sensor to collect the applied force load in real time, use the indirect measurement method to obtain the torque signal, transmit the collected signal to the control system of the loading device for data processing, and finally feed back to each load control device, including the output The electric signal acts on the electric proportional valve to control the movement of the cylinders 4, 18, 25, 28, and acts on the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com