Closure method of large-span continuous steel truss arch

A long-span, steel truss technology, applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

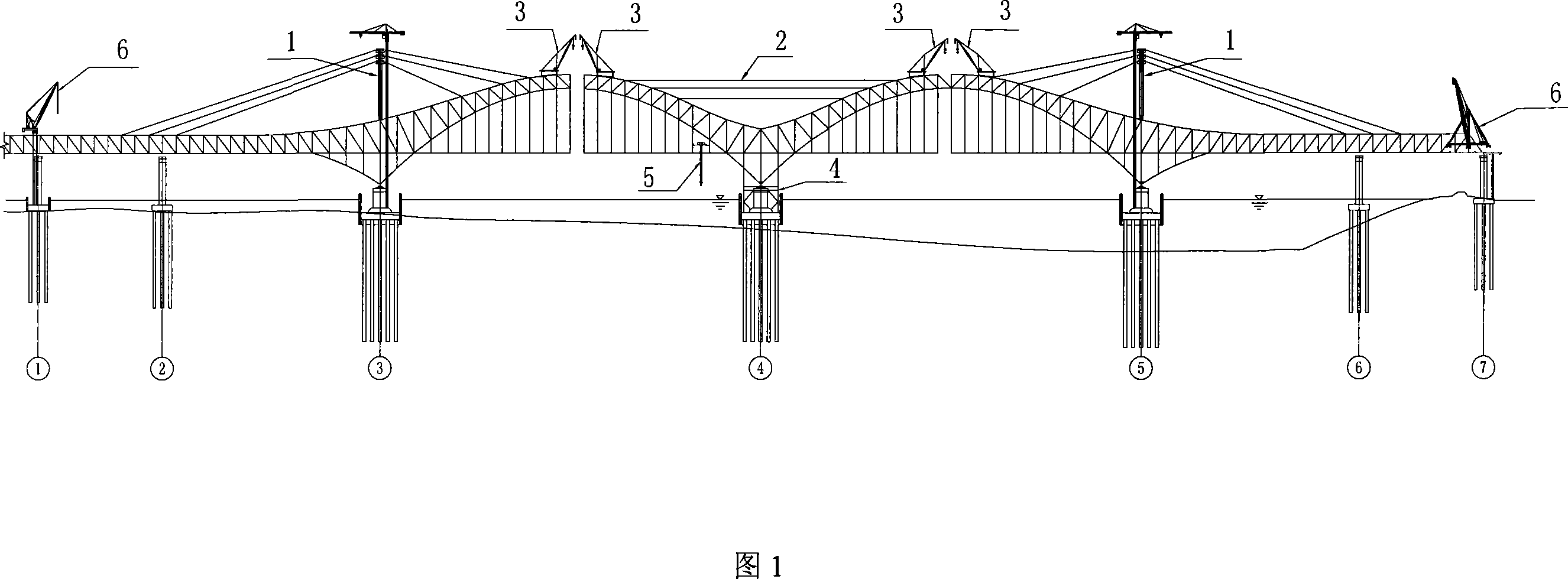

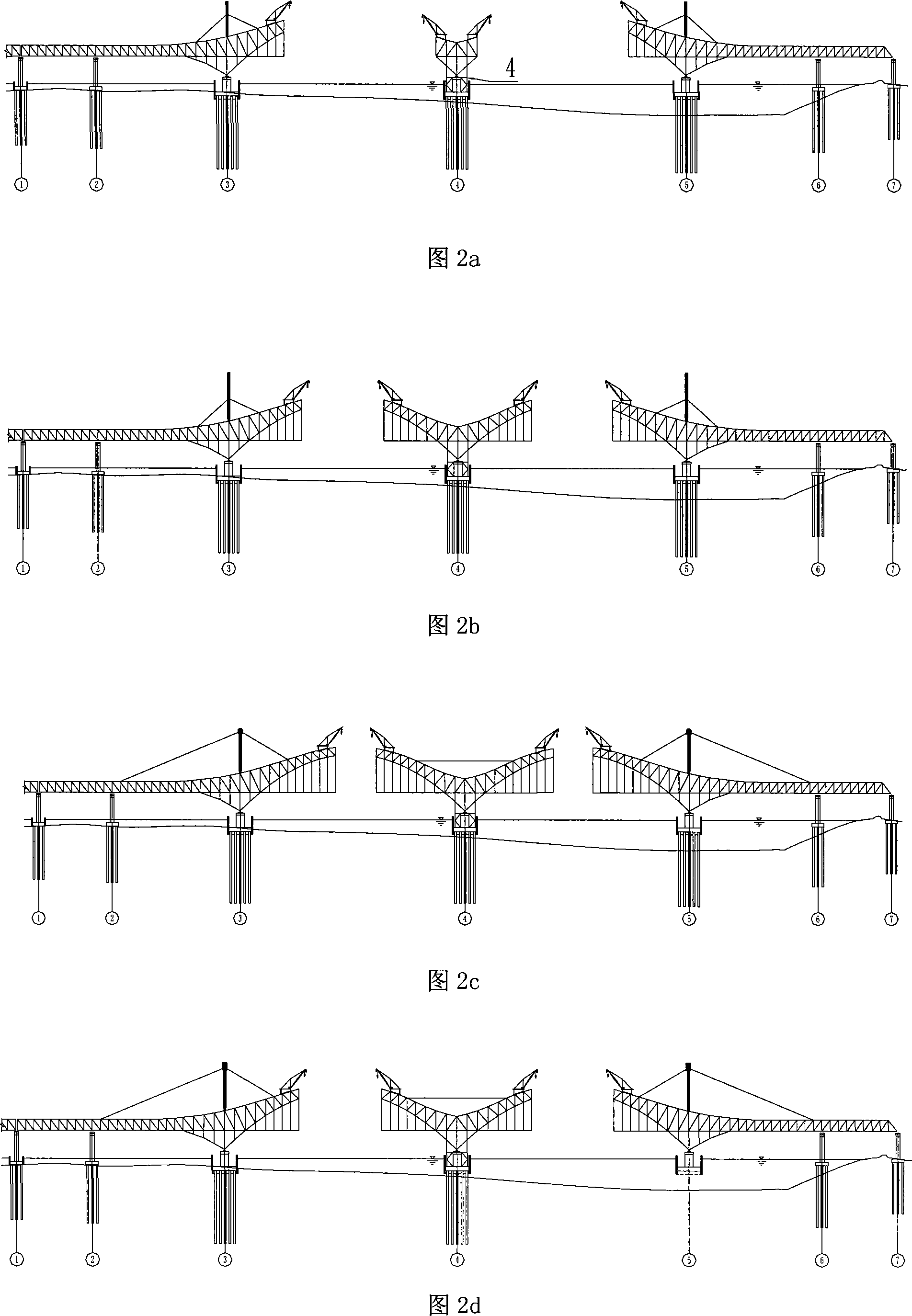

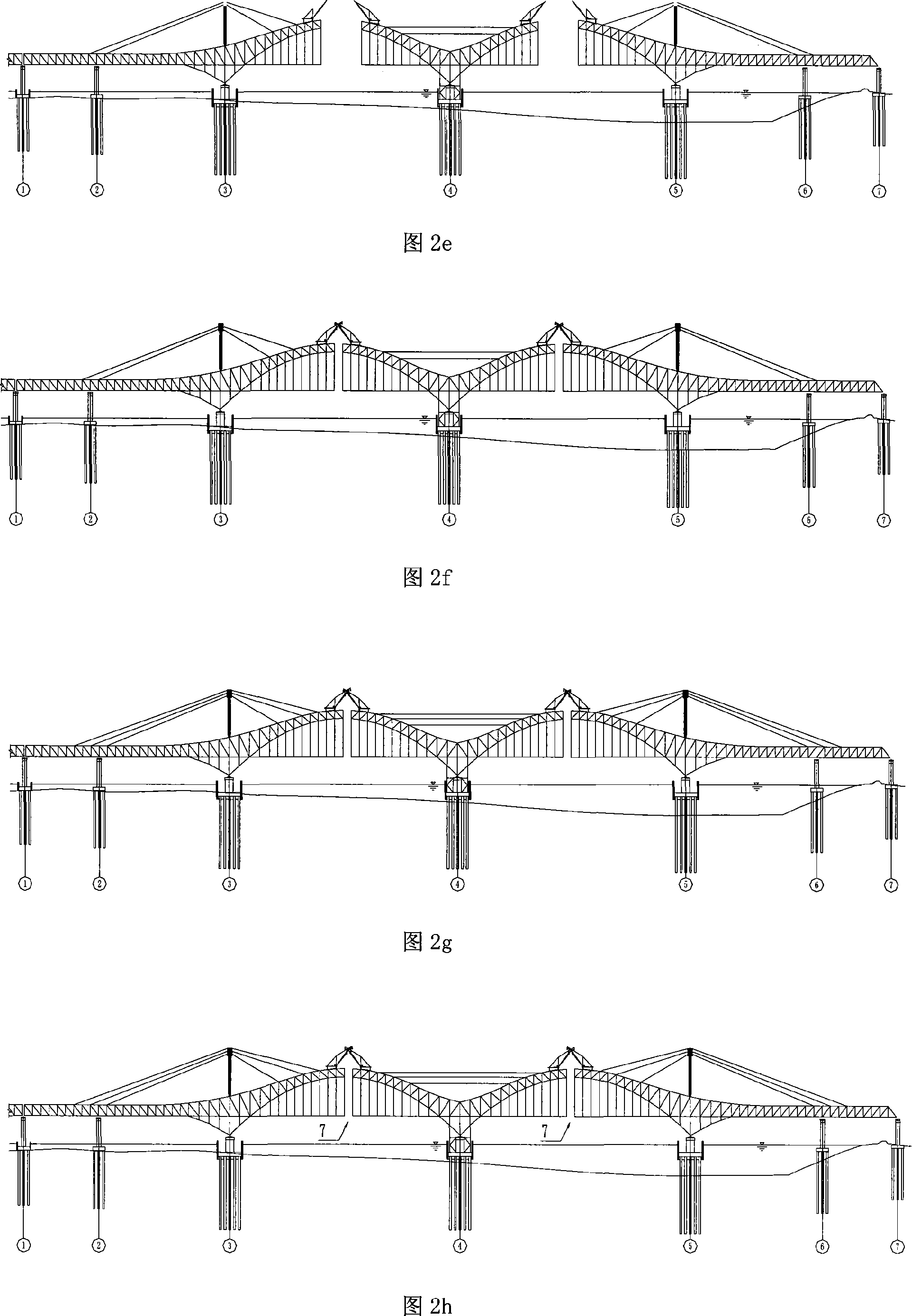

[0025] (1) Three-layer sling tower dense cable system, see Figure 3.

[0026] The dense cable system of the sling tower is used for the erection of the steel truss arches of 3# and 5# piers respectively; the height of the sling tower, the anchor point of the cable and the selection of the inclination angle must ensure the safety of the steel truss arch during erection. And adjust the closing mouth to a suitable position when the closing is satisfied. The lower end of the tower column is hinged with the reserved hinged seat plate of the upper chord node of the steel truss arch, and the assembly begins after the steel beams of the side spans are closed.

[0027] The stay cable of the sling tower is made of high-strength parallel steel wire, covered with a PE protective layer, anchored by anchor boxes at the upper and lower ends, and anchored by cold cast anchors, and the lower end of the sling is a tension end. The length of the cold cast anchorage should be carefully selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com