Target automatic separation method based on immune magnetic beads and separating mechanism

An immune magnetic bead and automatic separation technology, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of treatment effect, separation effect, mixing time can only be controlled by humans, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

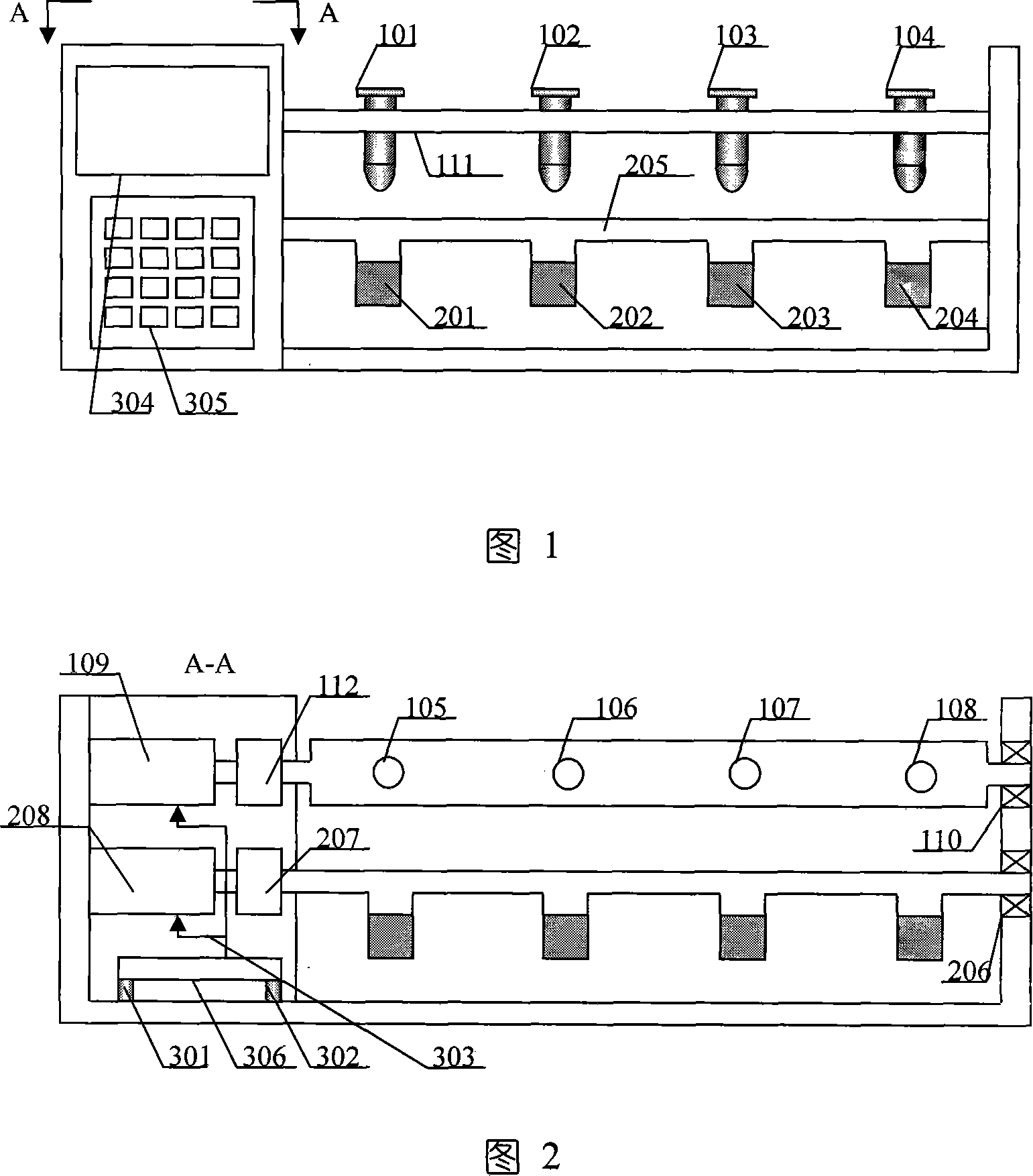

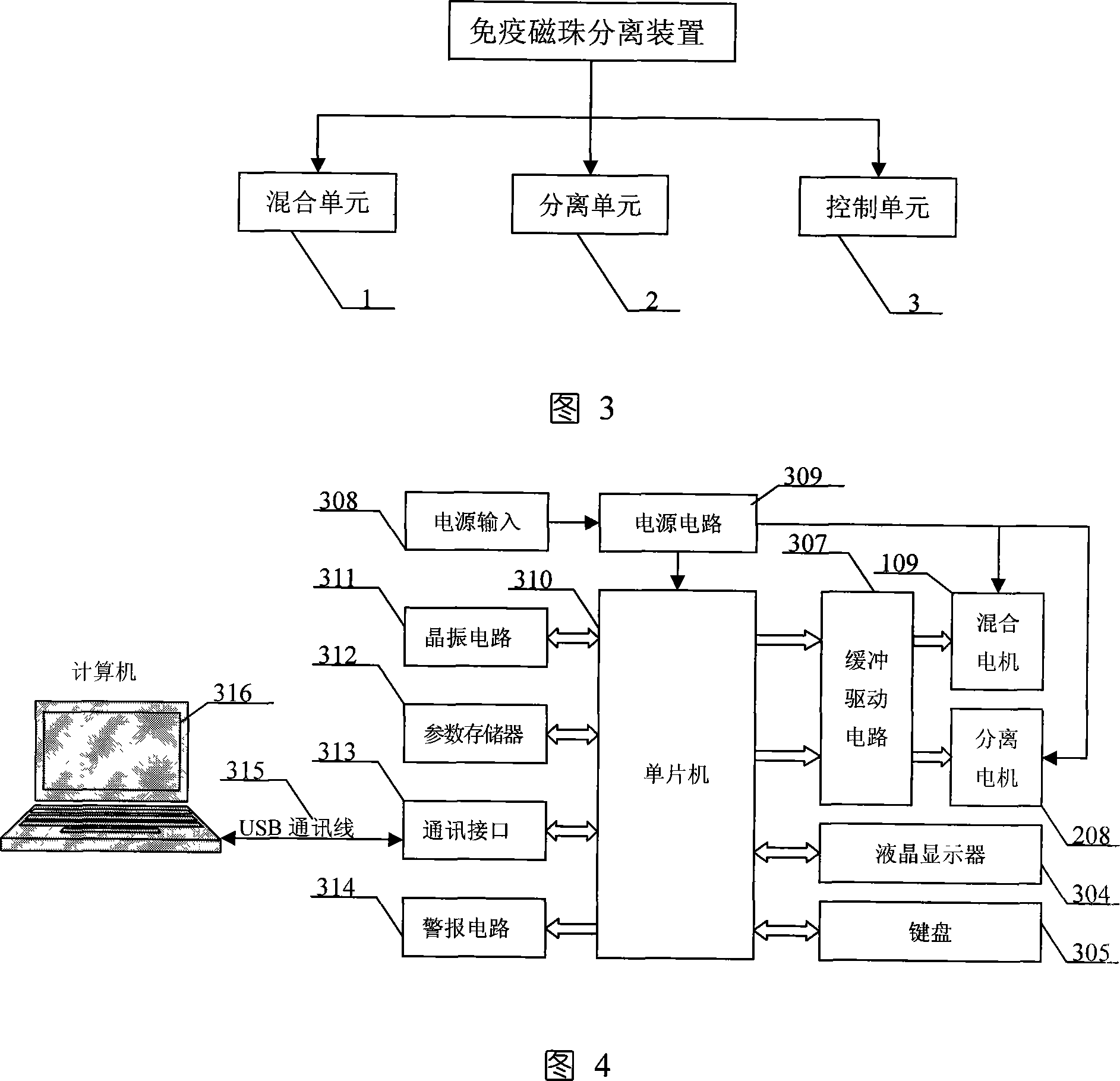

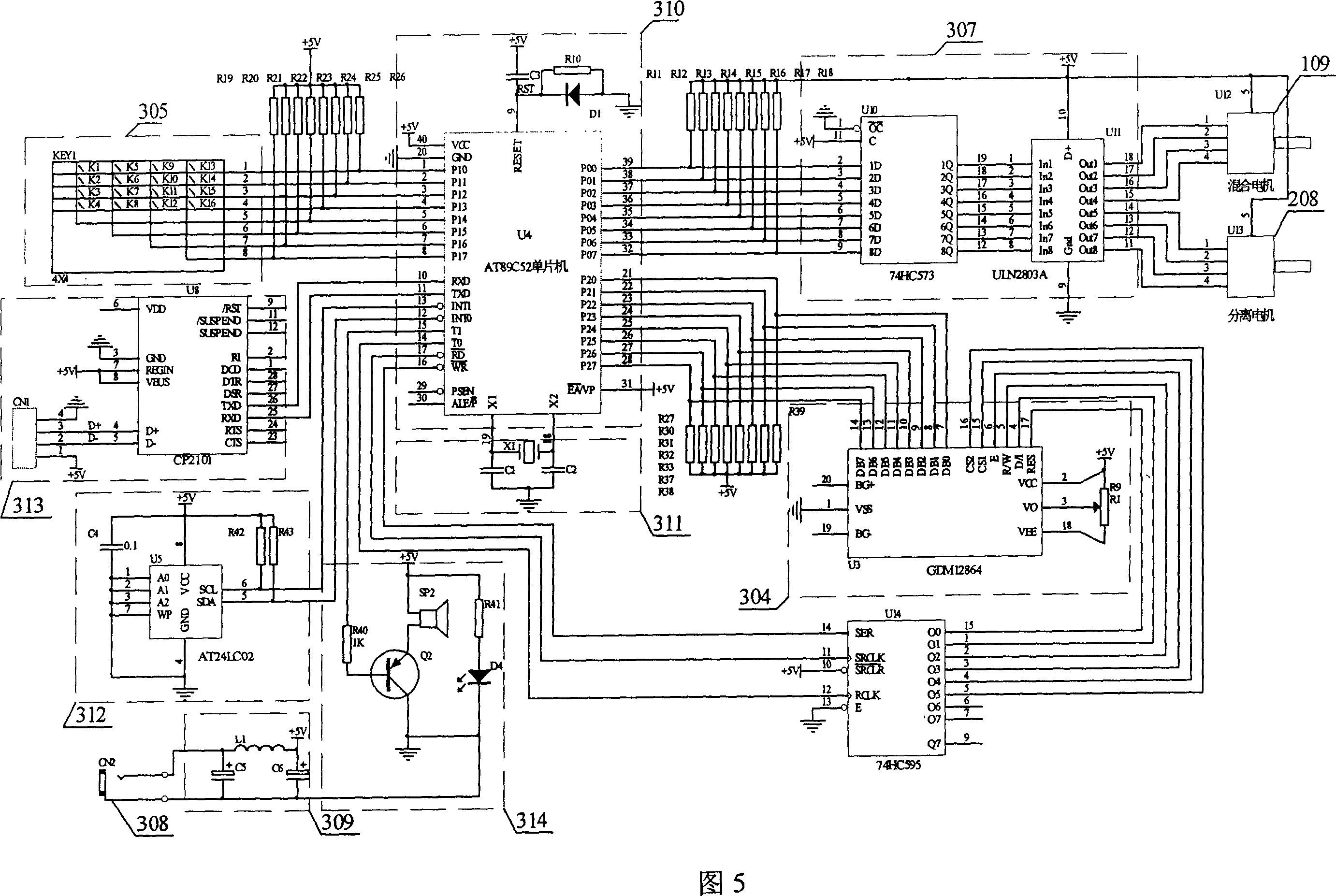

[0019] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, the present invention comprises mixing unit 1, separation unit 2 and control unit 3; Wherein:

[0020] 1) Mixing unit 1, 4 sample tubes 101, 102, 103, 104 are respectively fixed in the respective sample holes 105, 106, 107, 108 on the mixing sample plate 111, and one end of the mixing sample plate 111 passes through the mixing motor 109 The first coupling 112 is connected, and the other end of the mixing sample plate 111 is connected to the casing through the bearing 110; the mixing motor 109 is electrically connected to the control unit 3 through the control cable 303;

[0021] 2) Separation unit 2, 4 separation magnets are respectively fixed on the separation transmission plate 205, and the 4 separation magnets correspond to the 4 sample tubes fixed on the mixing sample plate 111 one by one, and one end of the separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com