Device for taking and putting material carrier of ageing oven

A pick-and-place device and an aging furnace technology, applied in the field of aging furnaces, can solve problems such as unfavorable automation of aging processing of electronic materials and increased production labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the structure, characteristics and realized effects of the present invention in detail, a preferred embodiment is given and described as follows with accompanying drawings.

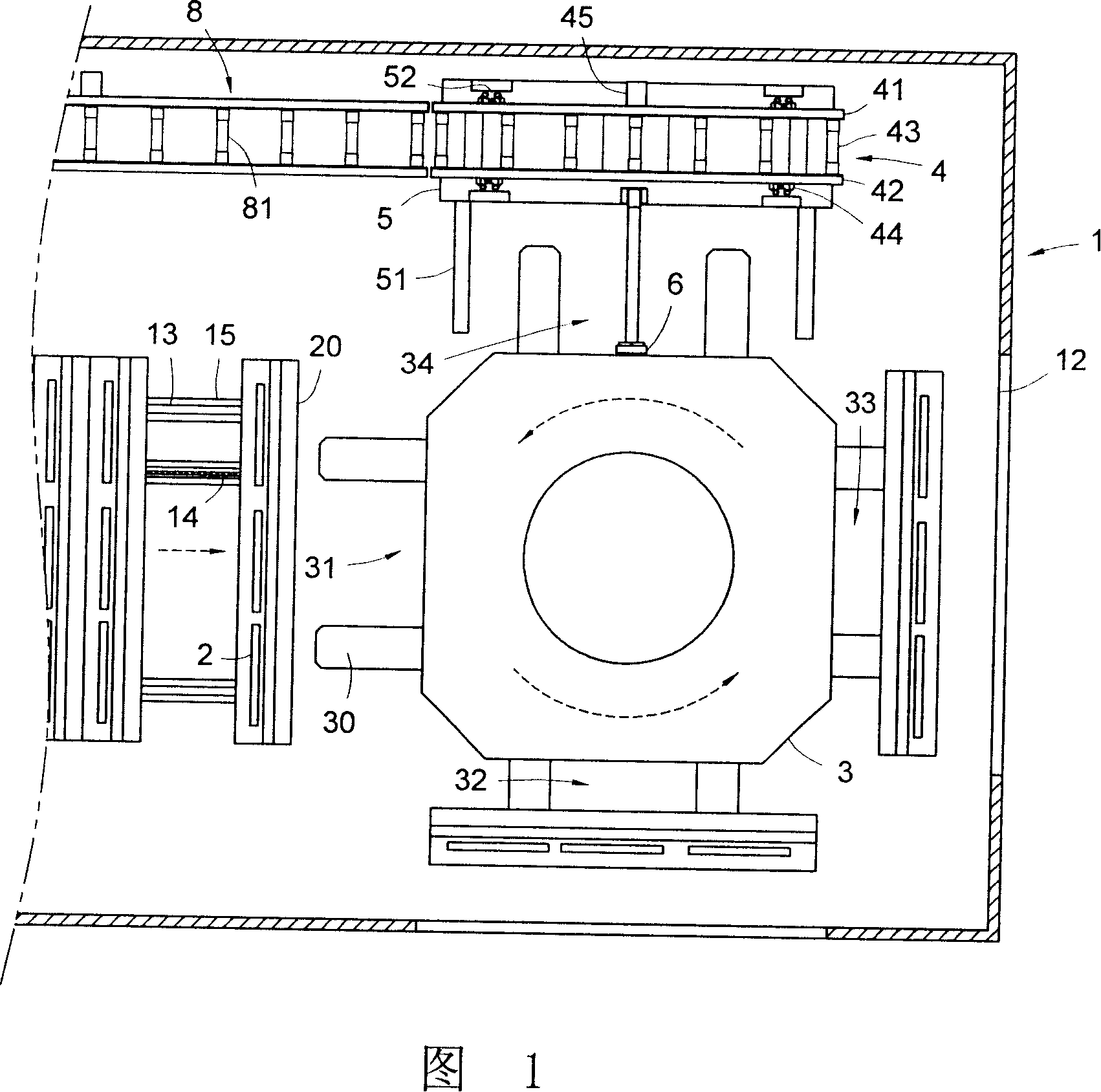

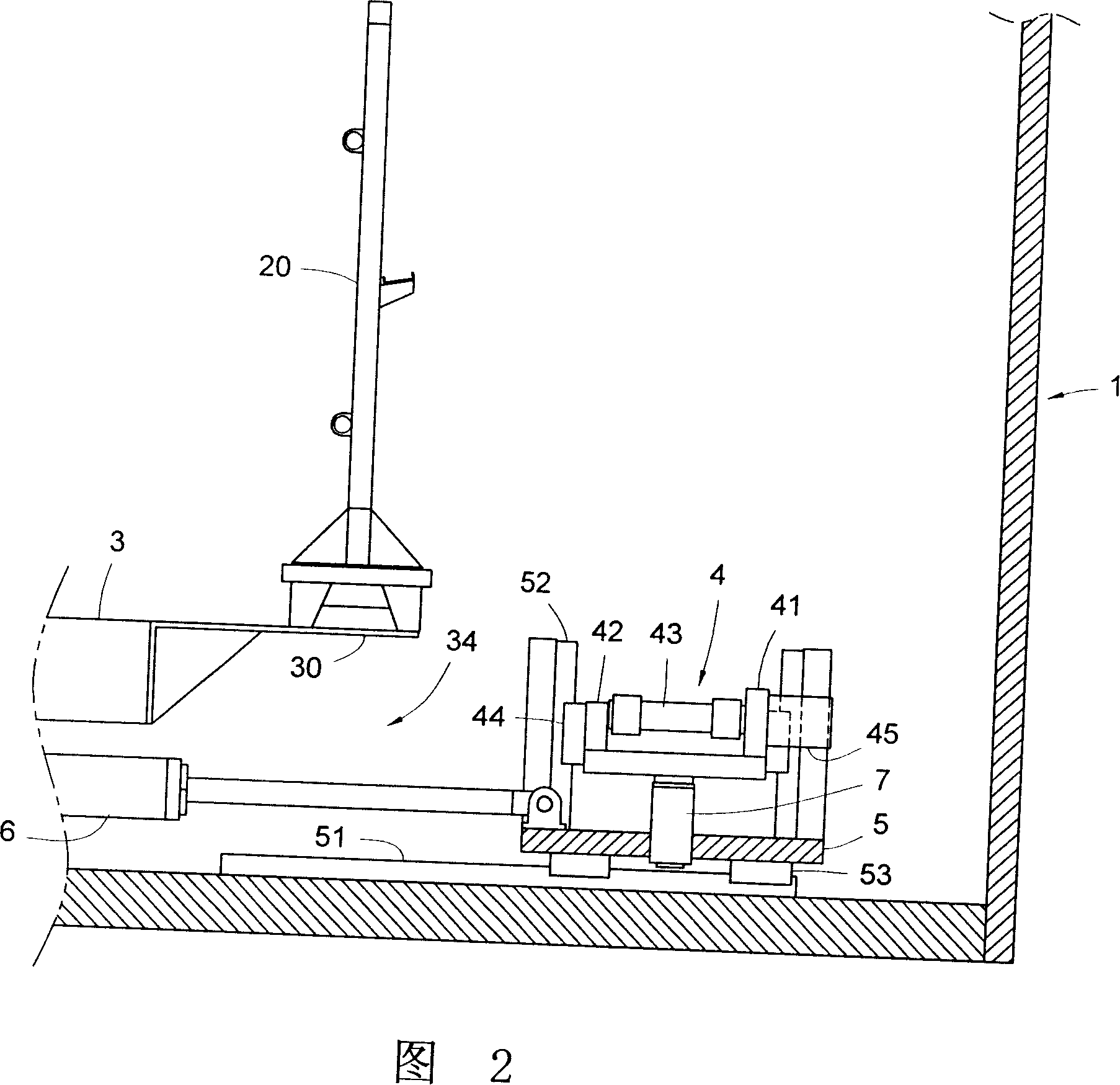

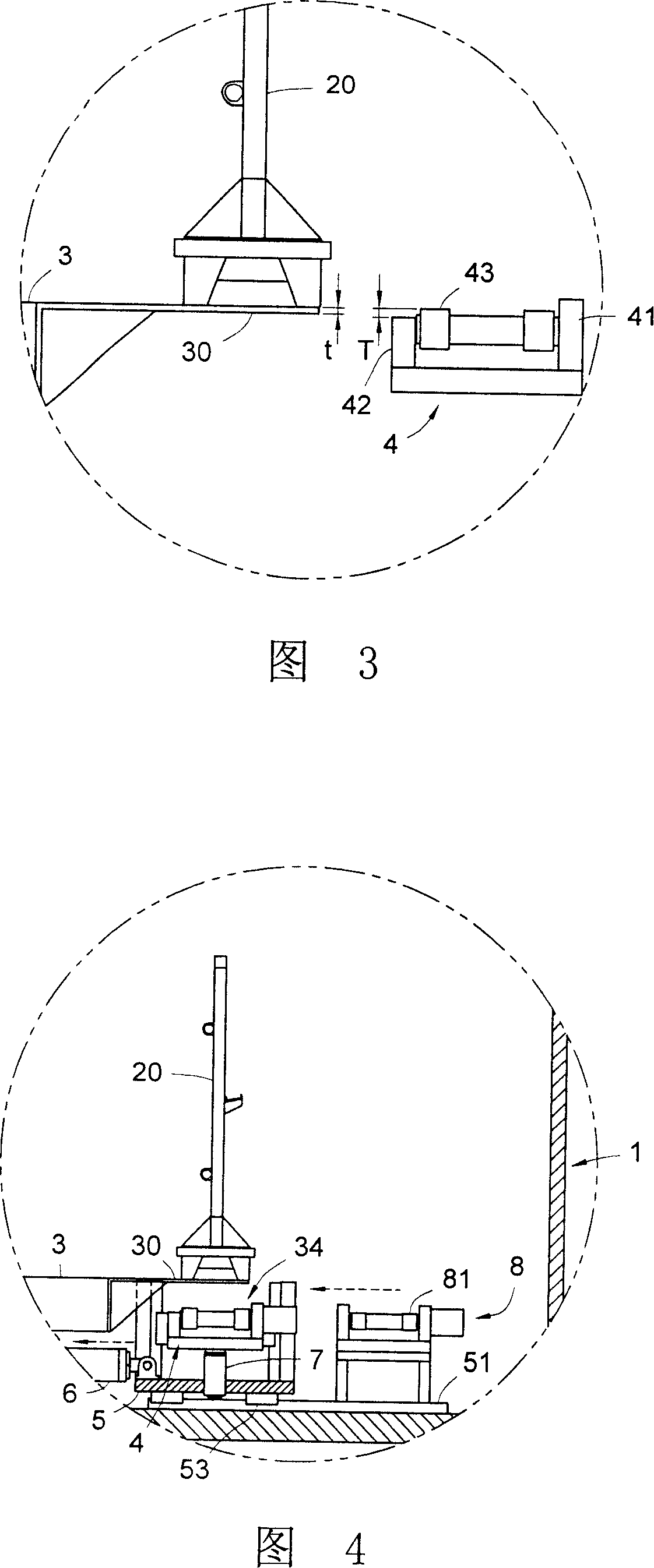

[0030] As shown in Figure 1 and Figure 2, it is a cross-sectional view of the configuration environment of the embodiment of the present invention, including:

[0031] An aging furnace 1 is provided with two supporting frames 15 inside, and a track 13 is respectively arranged on each supporting frame 15, and a transmission chain 14 is arranged between each supporting frame 15, and a plurality of The carrier 20 of the electronic material 2 is driven by the transmission chain 14 to move.

[0032] A turntable 3 is arranged inside the outlet end 12 of the aging furnace 1 , and a plurality of carriers 30 are arranged around the turntable 3 , which can hold the carriers 20 driven by the chain 14 inside the aging furnace 1 . Simultaneously, the turntable 3 can be fixedly rotated at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com