Method for suppressing harmonic current of high-power AC motor

A technology of AC motor and harmonic current, applied in the direction of AC motor control, electrical components, control system, etc., can solve the problems of unstable output power, obvious motor jitter, high cost of high-power vacuum cleaner governor, and achieve economical utilization resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

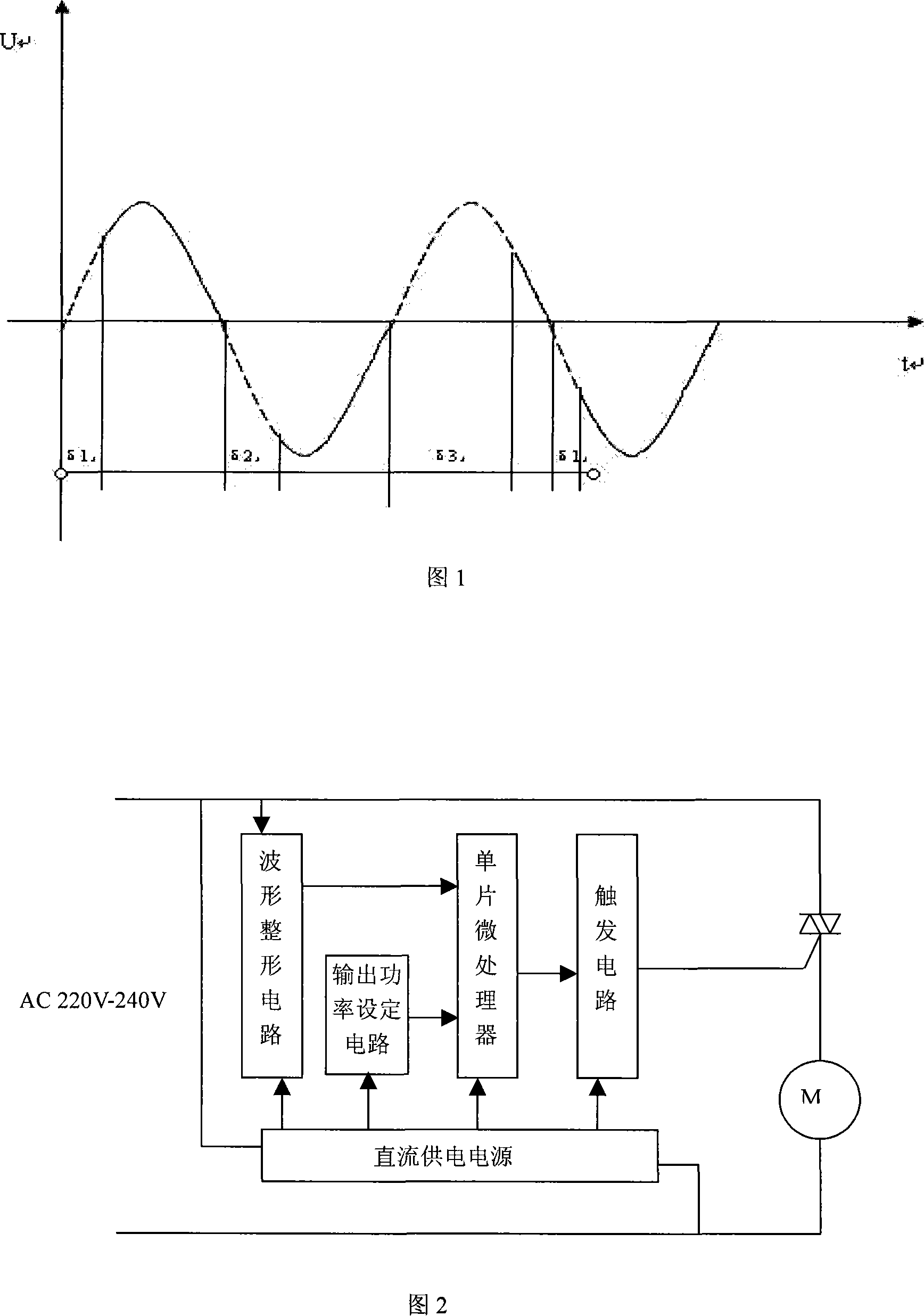

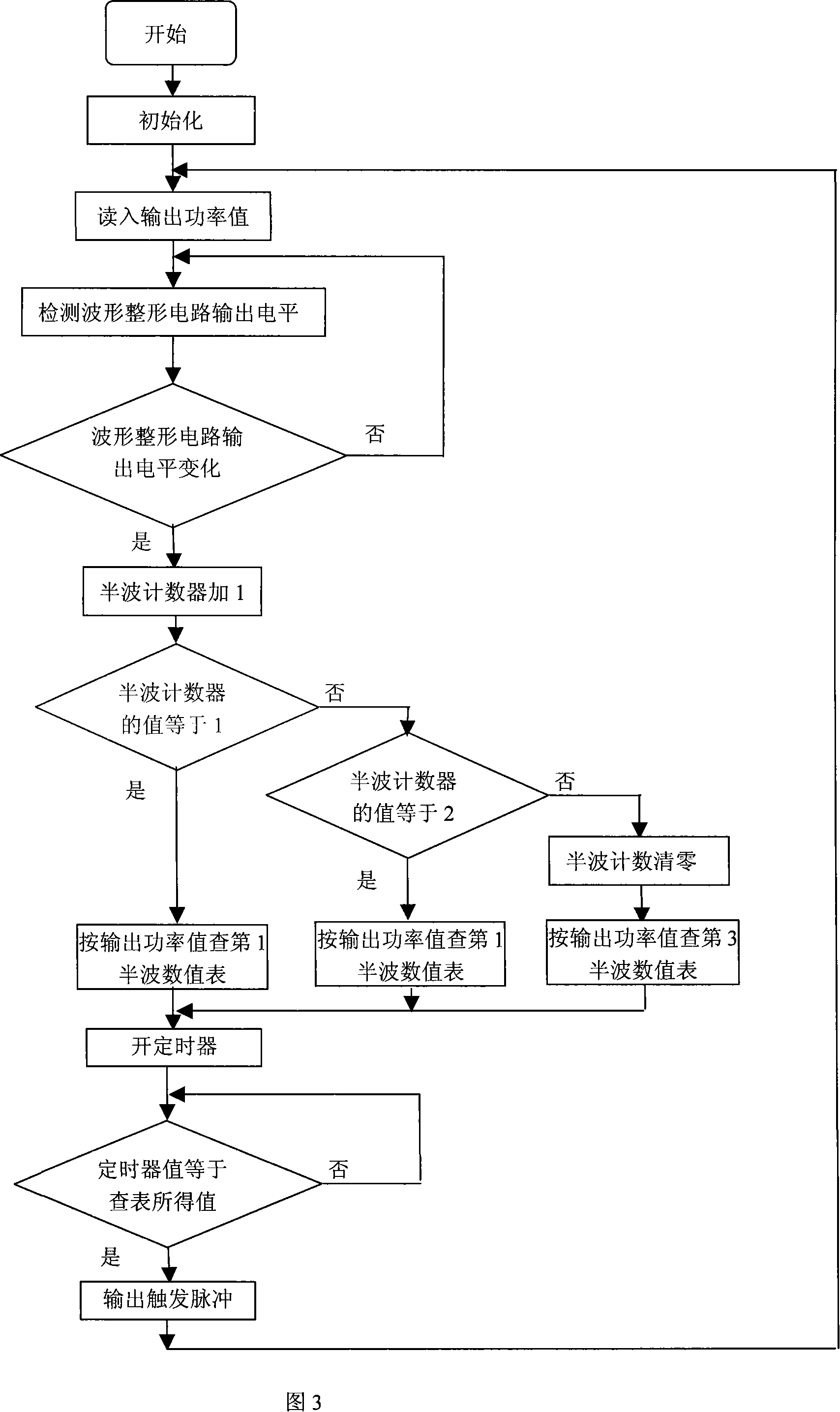

[0010] After testing the existing traditional symmetrical chopping thyristor phase-shifting circuit, it is found that when the phase-shifting angle is 90 degrees, the harmonic current value is the largest, which seriously exceeds the requirements of EMC standards. If the phase angle is lower, the harmonic current value will be significantly reduced. Therefore, it is assumed that in the three consecutive half-waves with a phase shift angle of 90 degrees, the middle phase shift angle remains unchanged, and the two phase shift angles before and after one increase and the other decrease, and the average power remains unchanged. This should enable The harmonic current value is greatly reduced and the output power of the motor can be stably controlled. After testing, the even-order harmonic current value will increase slightly, while the odd-order harmonic current will be greatly reduced, which shows that this method is effective and feasible.

[0011] As shown in Figure 1, the AC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com