Continuous self-cleaning reverse-pressure over-flow filtering device

A filtration device and overflow technology, applied in filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of small filtration area, large power consumption, high labor intensity, etc., and achieve high filtration accuracy and power. The effect of small consumption and large filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

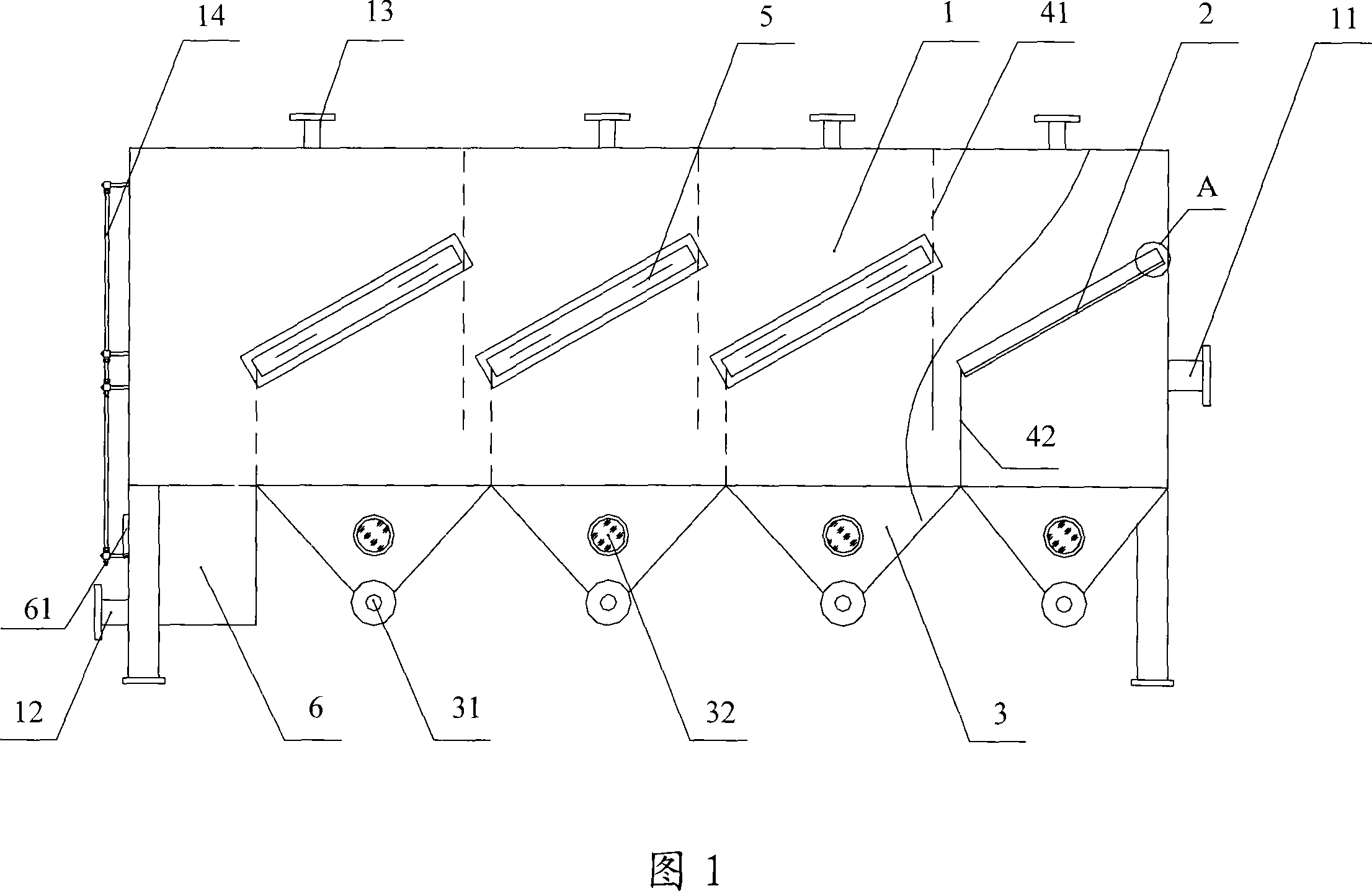

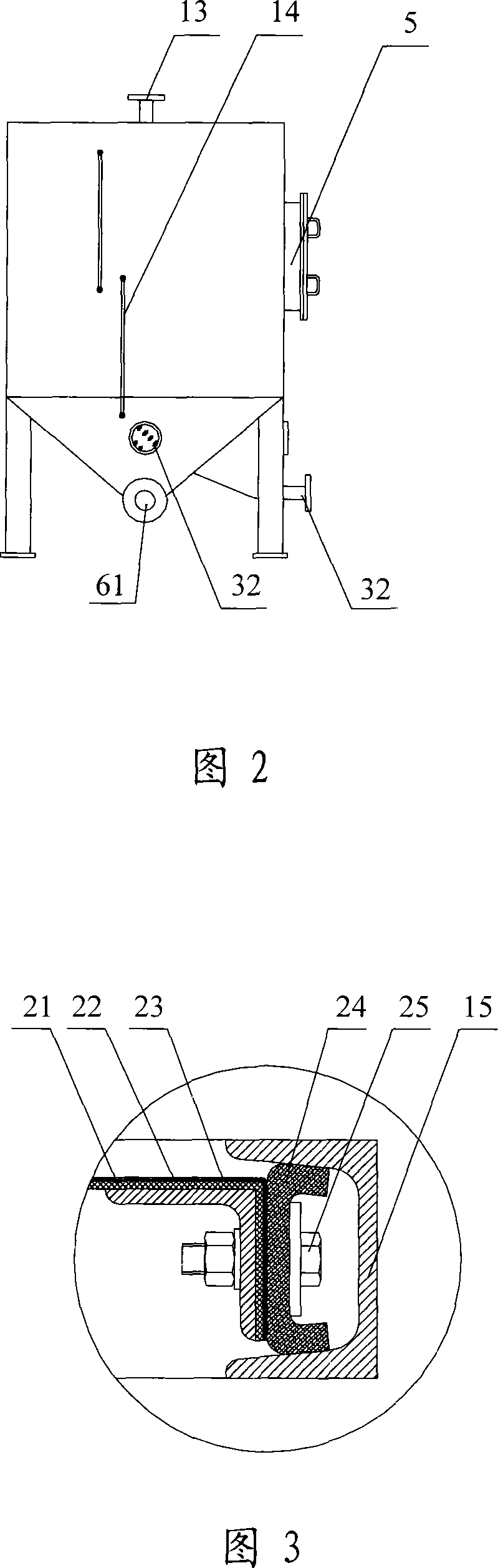

[0035] Referring to FIG. 1 , it is a structural schematic diagram of a specific embodiment of the continuous self-cleaning backpressure overflow filter device of the present invention. The continuous self-cleaning back pressure overflow filtering device includes an airtight casing 1, in this embodiment, the airtight casing 1 is a cube, on its left and right sides, is respectively provided with a material inlet 11 and a material outlet 12, and the The position of the feed port 1 is higher than the discharge port 12. Inside the airtight casing 1, there are three sets of partitions, which divide the entire internal space into four relatively independent spaces, and a filter plate 2 is arranged in each space, and the shell opposite to the filter surface of the filter plate 2 The lower part of the body is provided with a filter residue collector 3, so that the partition, the filter plate 2 and the filter residue collector 3 constitute a filter unit. Wherein, the partitions are upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com