Piezoelectric ultrasonic transducer

A piezoelectric transducer and piezoelectric ultrasonic technology, which is applied to sound-producing instruments, instruments, fluids utilizing vibration, etc., can solve the problems of low power density, low structural strength, large radial size, etc., and improve the overall structural strength. , the effect of improving power capacity and electromechanical conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described in detail below by way of examples.

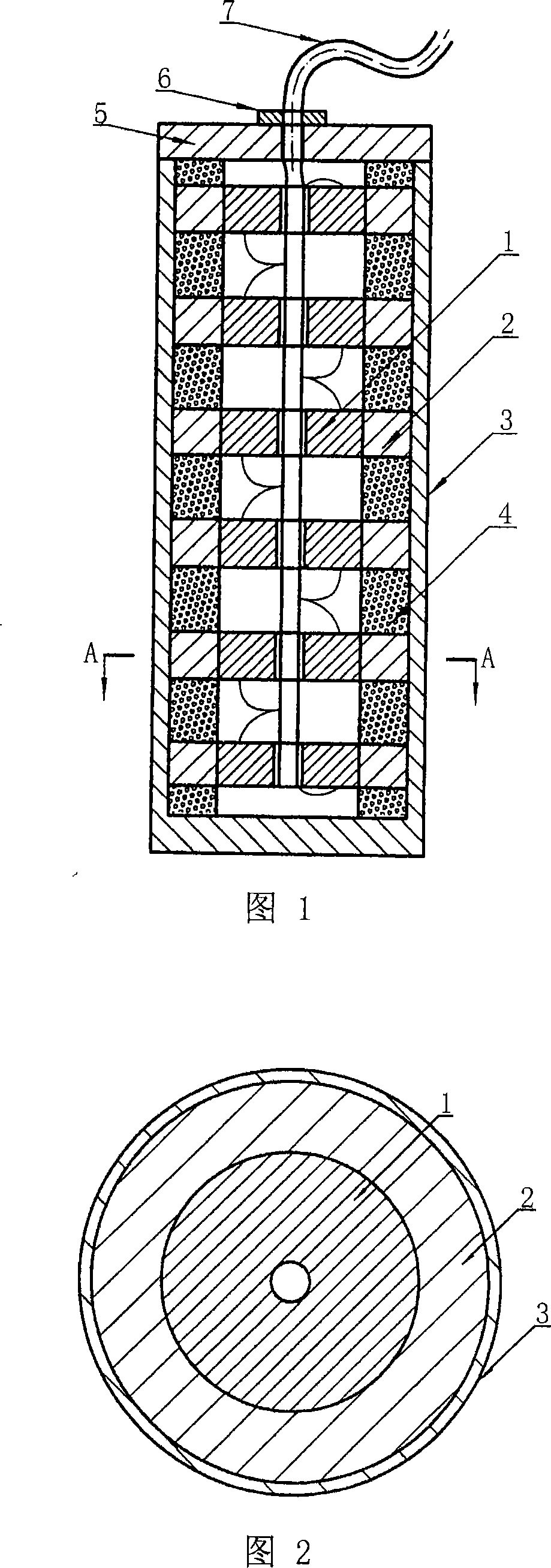

[0020] Referring to accompanying drawing 1 and accompanying drawing 2, a kind of piezoelectric ultrasonic transducer comprises piezoelectric ceramic disc 1, prestressed ring-shaped cover plate 2, cylinder body 3, insulating ring pad 4 and end cover 5, wherein, piezoelectric The ceramic disk 1 adopts a circular piezoelectric ceramic disk, and a through hole is arranged in the middle of the piezoelectric ceramic disk 1; the prestressed annular cover plate 2, the cylinder body 3 and the end cover 5 are made of metal materials, and the insulating and vibration-isolating ring pad 4 Made of polyester fiber; the polarization direction of the piezoelectric ceramic disc 1 is the thickness direction, the two end faces of the piezoelectric ceramic disc 1 in the thickness direction are electrode surfaces, and the thickness of the inner edge of the prestressed annular cover plate 2 is the same as that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com