Loose discharging method for train container

A container and train technology, applied in the field of bulk unloading, can solve the problems of poor working environment, polluting the natural environment, spilling along the way, etc., and achieve the effects of saving bagging costs and labor costs, improving the environment, and reducing operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

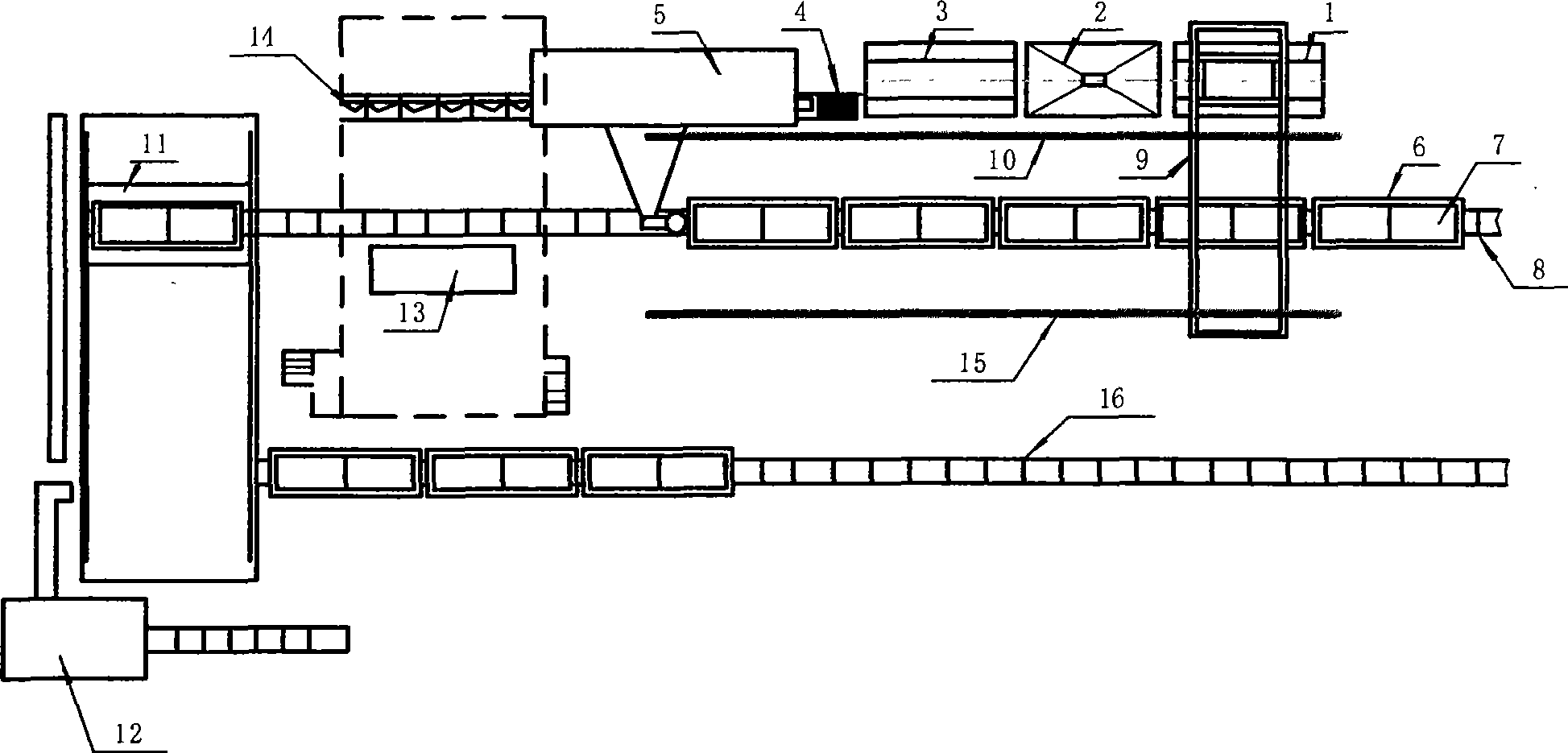

[0026] a. The locomotive aligns the wagon 6 to the working position where the steering machine 5 can function;

[0027] b. The gantry crane 9 sends the container 7 to the tilting platform A1 within the limits of the gantry crane track A 10 and the gantry crane track B 15 to unload the hook and return to lift another container, and at the same time, the tipping platform A1 starts unloading to the hopper 2, and then transport the bulk material to the warehouse through the belt conveyor under the hopper 2; after the gantry crane 9 lifts another section of container to the tilting platform B3, the decoupling operation lifts the empty container of the tilting platform A1 Be transported to reset on wagon 6, meanwhile, tipping platform B3 starts unloading. In such a cycle, the door crane unloads the containers within the effective range and returns them to the wagon 6;

[0028] c, the steering machine 5 starts to work, and the first batch of unloaded wagons 6 are transported to the ...

Embodiment 2

[0030] a. The locomotive aligns the wagon 6 to the working position where the steering machine 5 can function;

[0031] b. The gantry crane 9 sends the container 7 to the tilting platform B3 within the limit range of the gantry crane track A 10 and the gantry crane track B 15 to unload the hook and return to lift another container, and at the same time, the tipping platform B3 starts unloading to the hopper 2, and then transport the bulk material to the warehouse through the belt conveyor under the hopper 2; after the gantry crane 9 lifts another section of container to the tilting platform A1, the decoupling operation will lift the empty container on the tipping platform B3 Be transported to reset on the wagon 6, and meanwhile, the tipping platform A1 starts unloading. In such a cycle, the door crane unloads the containers within the effective range and returns them to the wagon 6;

[0032] c, the steering machine 5 starts to work, and the first batch of unloaded wagons 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com