Fastener for steel pipe scaffold butting

A technology of scaffolding and locking parts, which is applied in the connection of scaffolding, building structure support, building structure support, etc., can solve the problems of cost increase, cumbersome structure, low vertical bearing capacity index, etc., and achieve the goal of reducing manufacturing cost and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

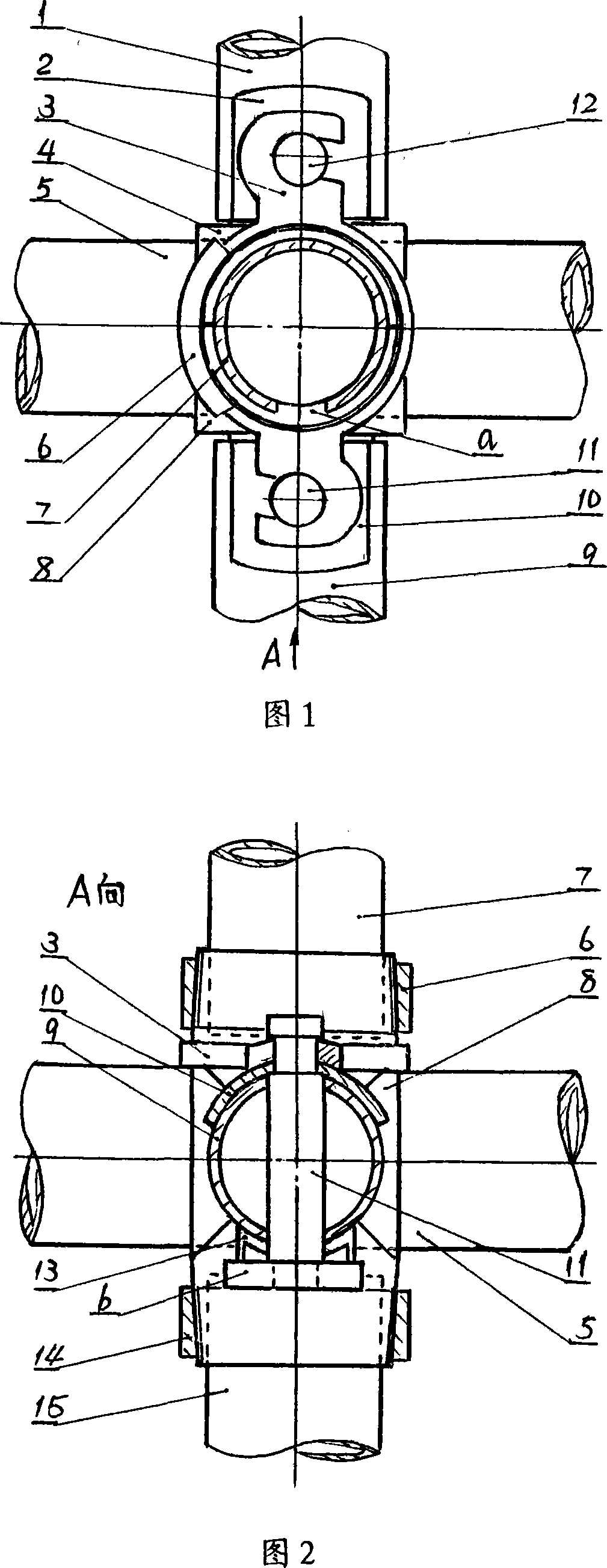

[0010] In Fig. 1 and Fig. 2: Insert vertical rods A(7), B(15) at the upper and lower ends of the half-opening and closing conical bolt bodies A(4), B(8); Passes through the main body in a radial direction; the two sides of the main body are respectively equipped with a seat body and accessories. As can be seen in the figure, the seat body B (b) is provided with a column B (11), an arc surface support plate B (13), and a semicircle with a socket in the middle. Pressing plate B (10), locking hook (3); On the inner wall of half open and close conical bolt body B (8), be provided with stop platform (a), its height≯1.5 millimeter; All bar parts are all in the present invention The end is provided with a radial hole with a diameter of 14 to 16 mm. This hole is used to replace the joints that must be welded at the ends of the rods in all butt joint layouts. It can be seen that it is very simplified.

[0011] Additional instructions: (1) During application, the frame body can be chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com