Bar code scaleplate production process

A technology of production process and process method, which is applied in the direction of measuring devices, instruments, surveying and navigation, etc., can solve the problems of high precision level, production, detection, high environmental conditions, infeasibility of invention and innovation, etc., and achieve high production efficiency , high degree of automation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

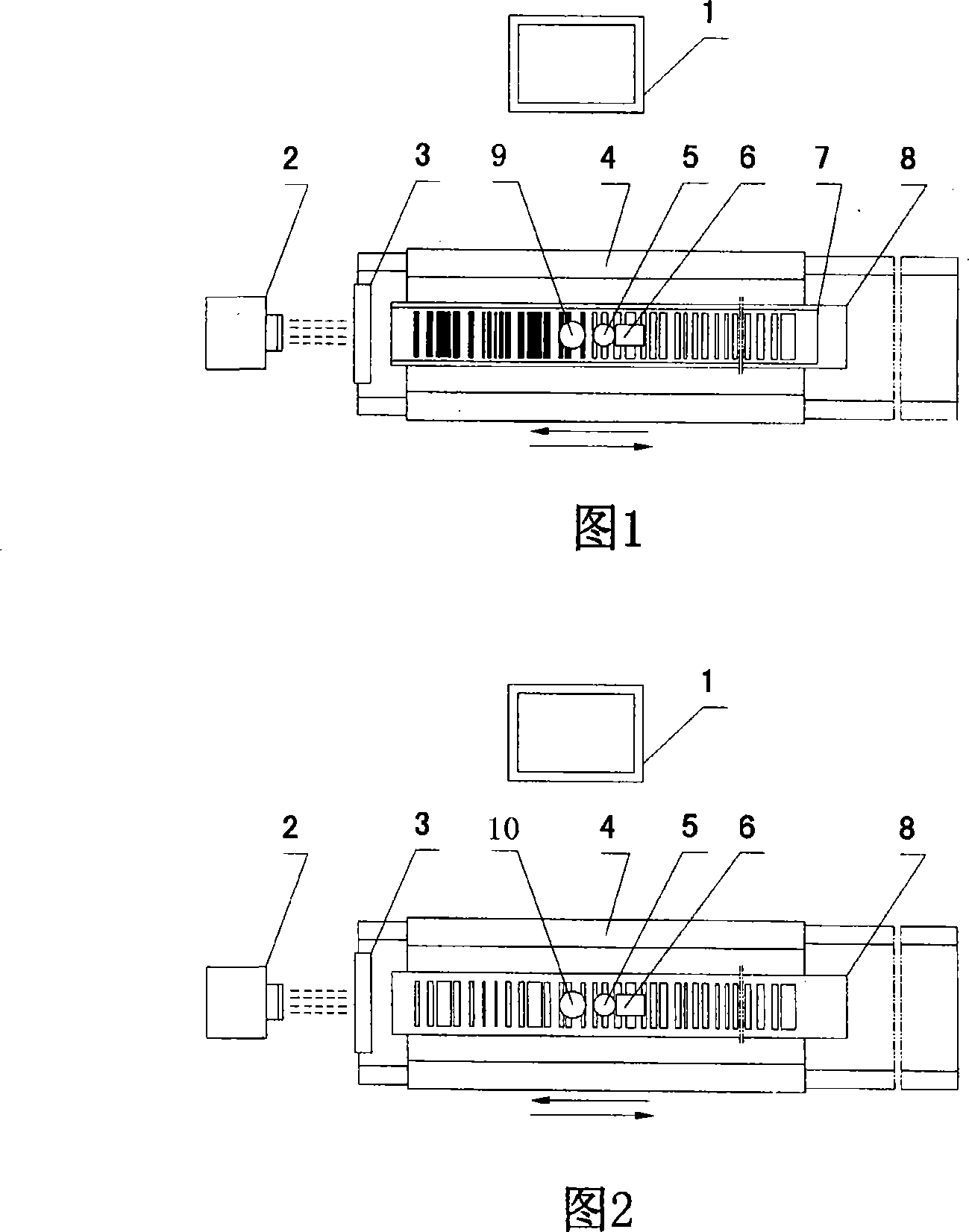

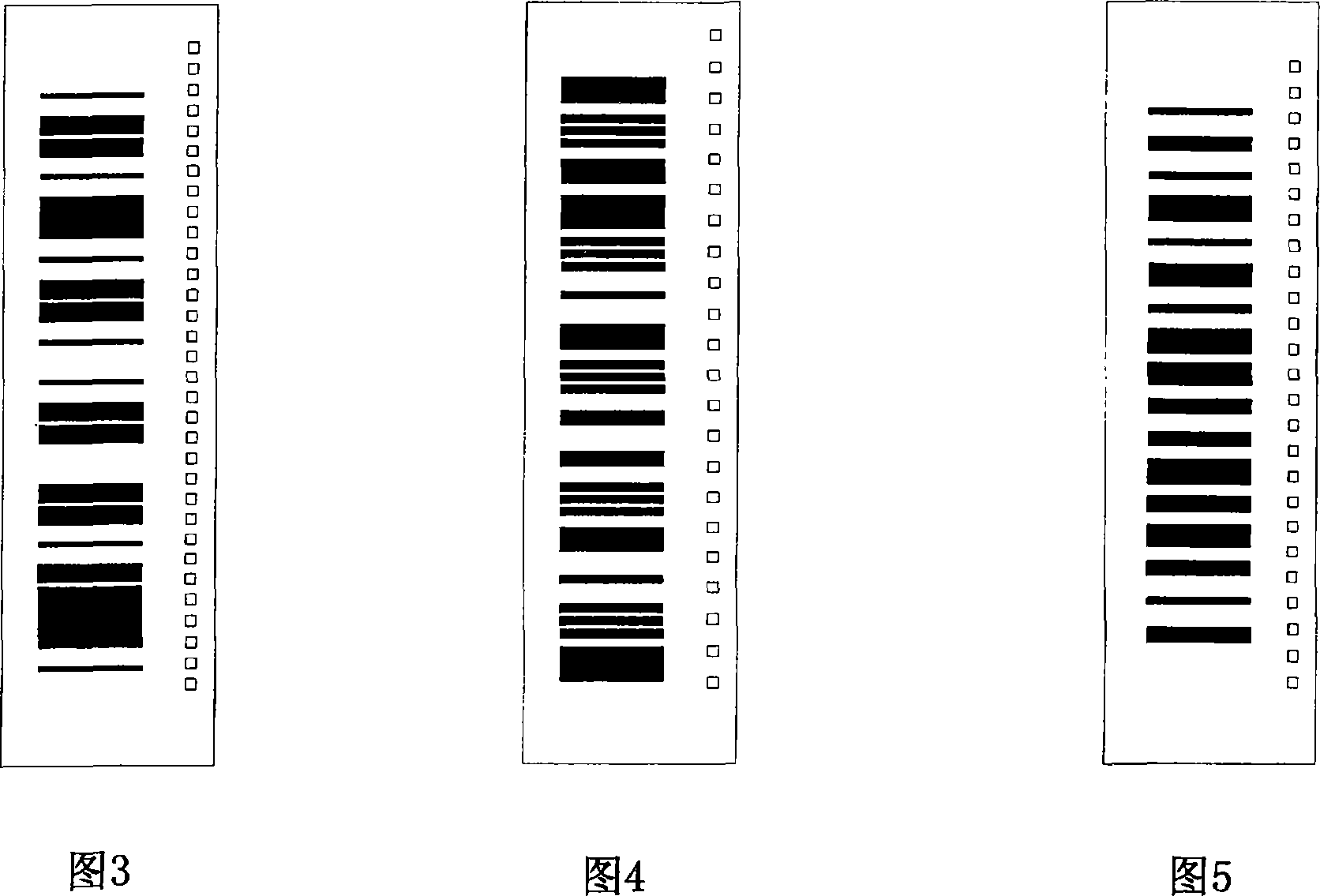

[0030] The method of the present invention is the technological method that adopts automation, semi-automation, manual mode to produce correlation method, geometric method, phase method and other mathematical principle bar code graphic scales, specifically comprises the following several:

[0031] 1) The production process of spraying barcodes with templates;

[0032] 2) The production process method of laser burning barcode mode;

[0033] 3) The production process of spraying barcodes with manual templates;

[0034] 4) The production process method of screen printing barcode mode;

[0035] 5) The production process method of etching barcode.

[0036] And the implementation of other production technology that this patent includes, reaches to produce various barcode graphic ruler products.

[0037] The purpose of the present invention is to provide a production process for producing various barcode graphic scales, and solve the problem of domestic instrument replacement with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com