Gear shaping machine with slide board type knife rack

A technology of gear shaping machine and tool holder, which is applied to components with teeth, gear cutting machines, belts/chains/gears, etc. It can solve the problems of small stroke adjustment range, inability to meet the needs of processing strokes in time, and high technical requirements. The effect of enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

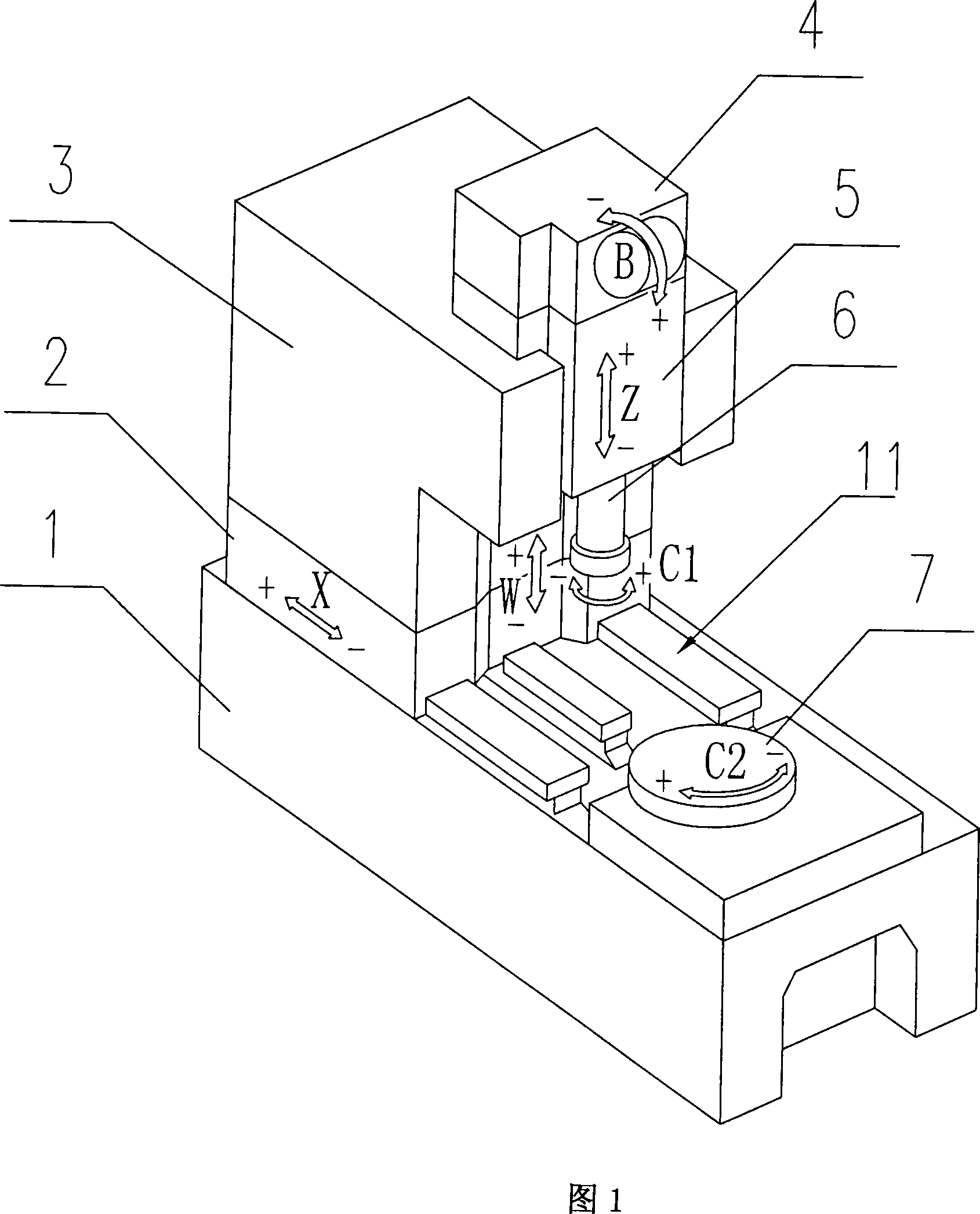

[0018] As shown in Figure 1-5.

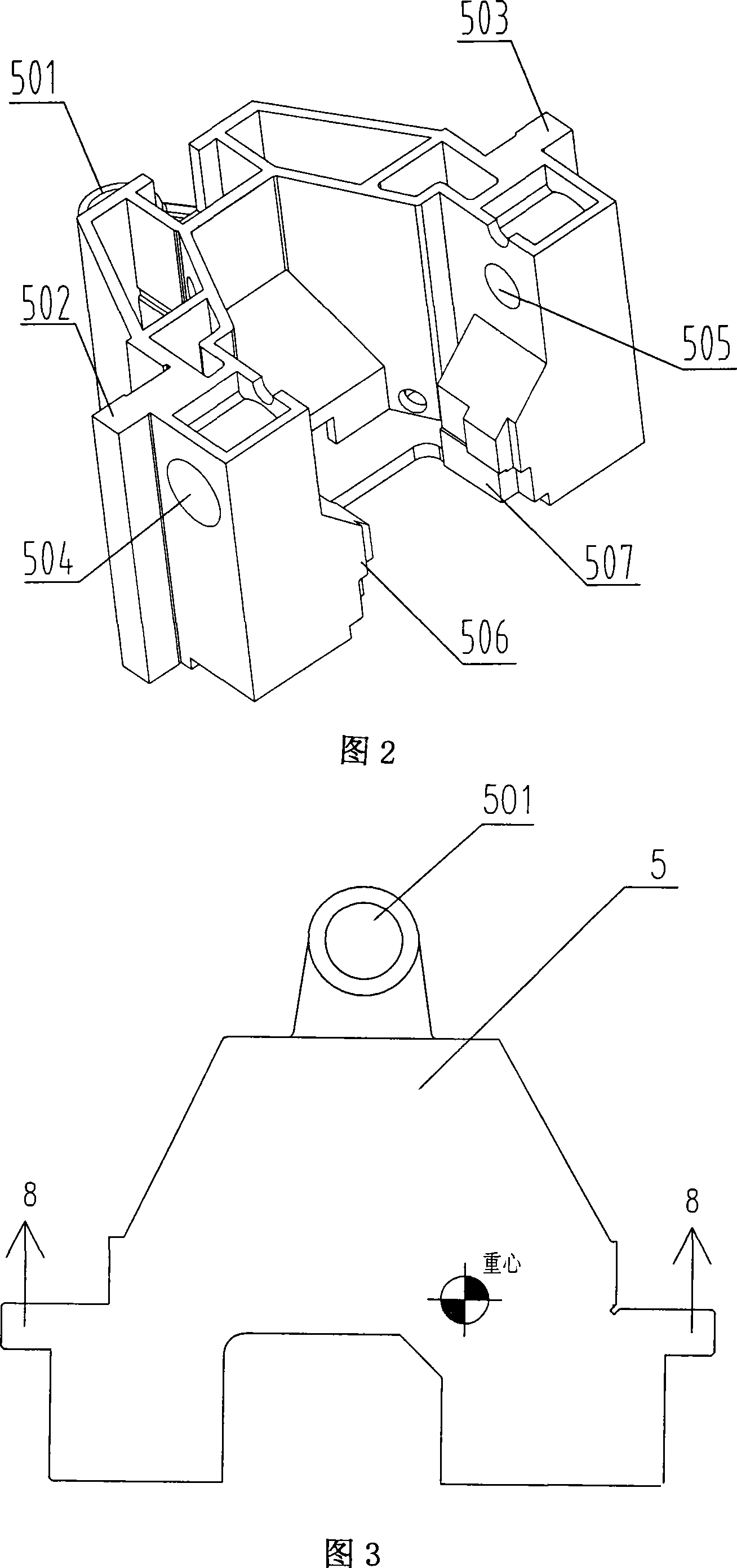

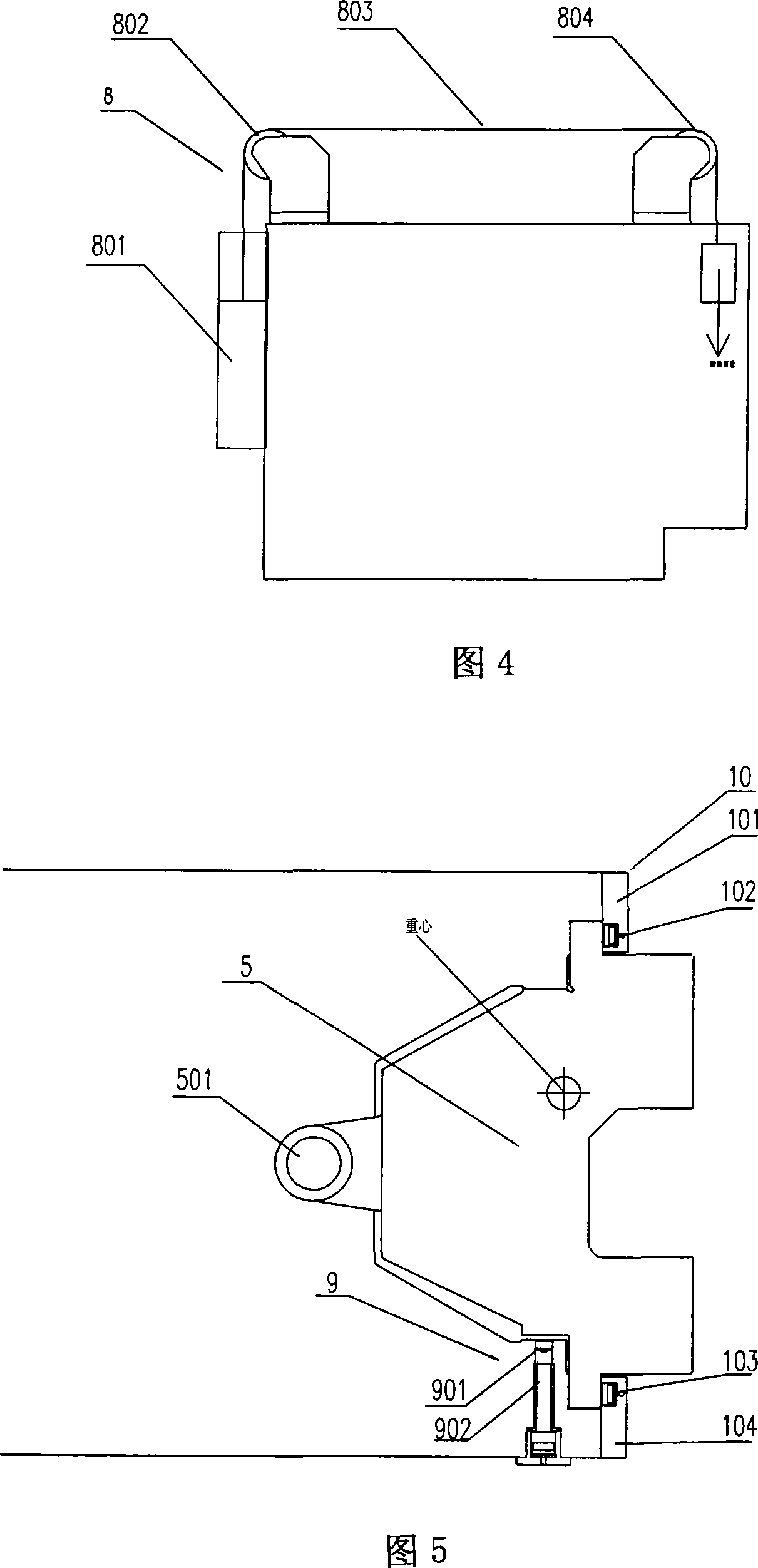

[0019] A gear shaping machine with a slide-type tool holder, including a bed 1, a radial slide 2, a column 3, a transmission box 4, a tool holder slide 5, a tool holder 6, and a workbench 7. As shown in Figure 1, the bed The body 1 is provided with a radial guide rail 11 and a workbench 7, a radial slide plate 2 is installed on the radial guide rail 11, a column 3 is installed on the radial slide plate 2, a tool holder slide plate 5 is installed on the column 3, and a tool holder slide plate 5 The upper part of the tool holder 4 is equipped with a transmission box 4, and the upper end of the tool holder 6 is installed in the tool holder slide plate 5 and connected with the transmission box 4; both sides of the tool holder slide plate 5 are respectively provided with a guide rail 502 that matches the axial guide groove on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap