Ampule automatic packing mechanism

A technology of automatic packaging and transmission mechanism, which is applied in the directions of packaging, packaging bottles, transportation and packaging, etc., to achieve the effects of improving unit economic benefits, small transmission driving force, increasing output and qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

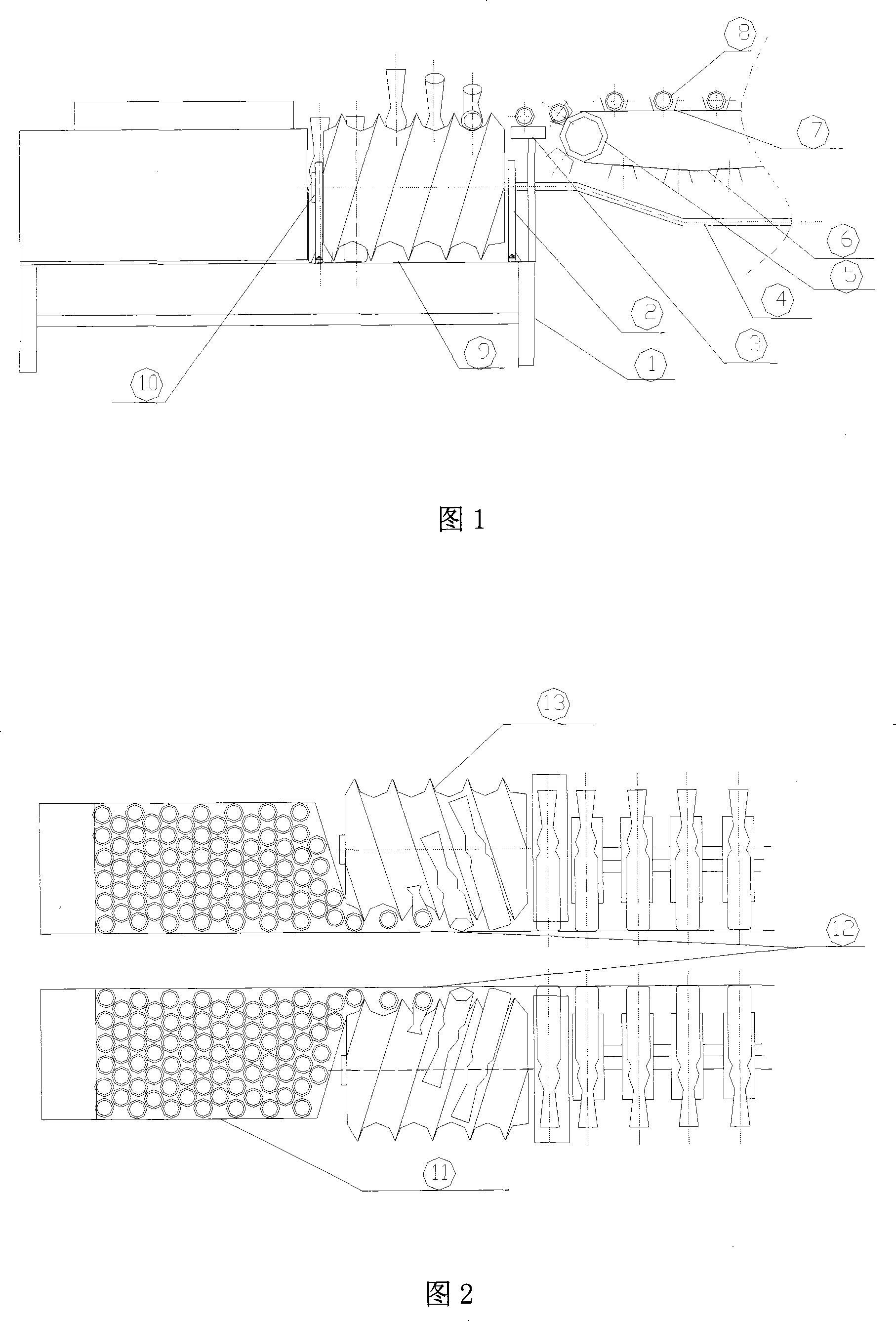

[0014] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

[0015] Referring to Figures 1-2, the ampoule automatic packaging mechanism includes a bracket 1, a transmission mechanism and a delivery arrangement mechanism, which is characterized in that the transmission mechanism and the delivery arrangement mechanism are installed on the bracket 1, and the transmission mechanism includes a transmission shaft support 2 and a pallet 3 , transmission shaft 4, sprocket 5, chain 6, placement groove 7, placement groove 7 is fixed on the chain 6, ampoule is placed in placement groove 7, the height of the chain 6 passing through the sprocket 5 supporting platform 3 is the same as the height of the sprocket 5 Adapt so that after the placement groove 7 with the ampoule 8 chain 6 passes through the sprocket 5, the ampoule rolls up to the pallet 3, the drive shaft support 2 is fixed on the bracket 1, and the drive shaft 4 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com