Air-float magneto motive friction-free suspension device

A suspension device, frictionless technology, used in the testing of measuring devices, instruments, machines/structural components, etc., can solve the problems of inability to meet the requirements of the frequency criterion, large nonlinear effects, and large error in measurement results, and achieve the same guarantee. Effects of Axiality and Parallelism Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

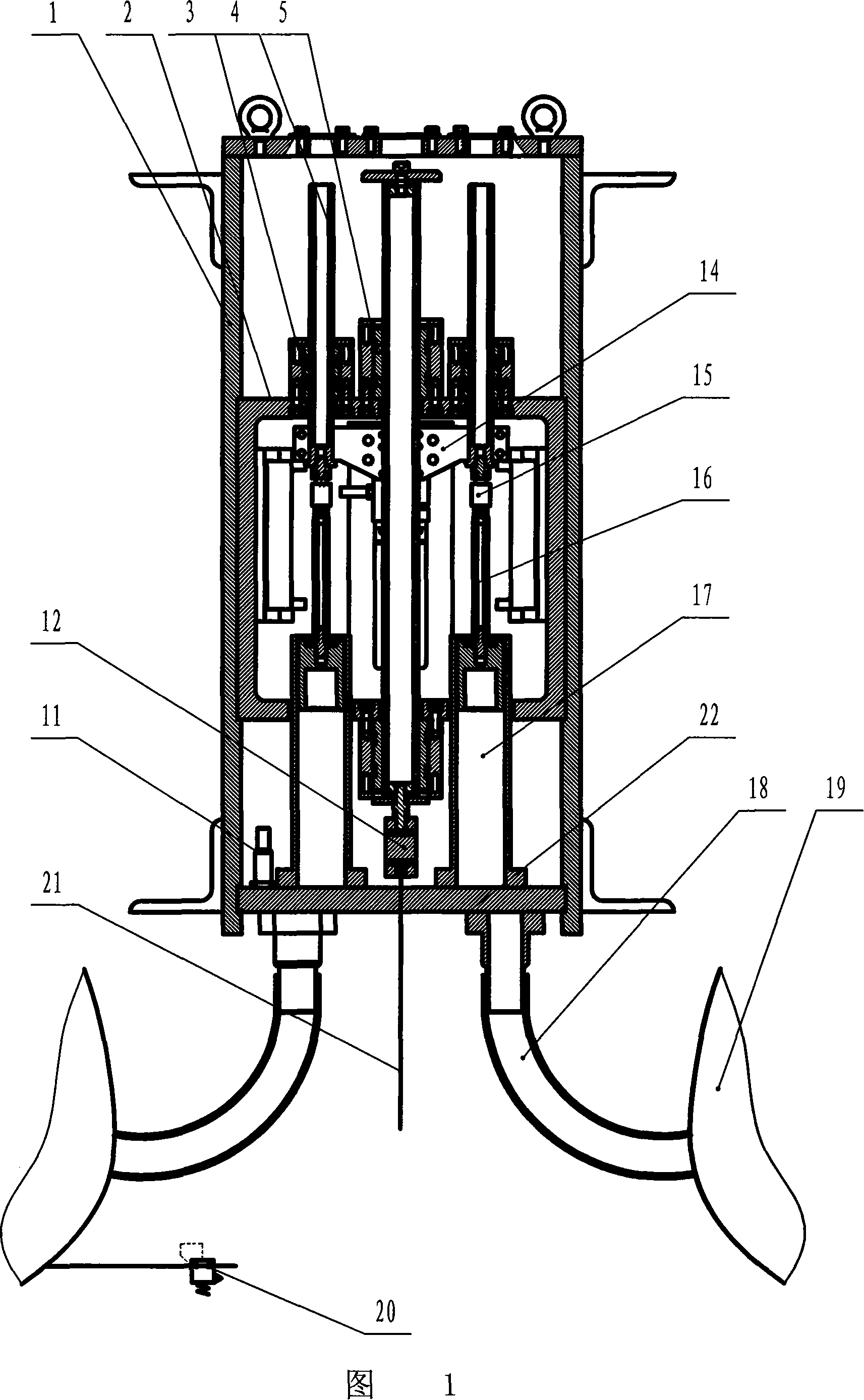

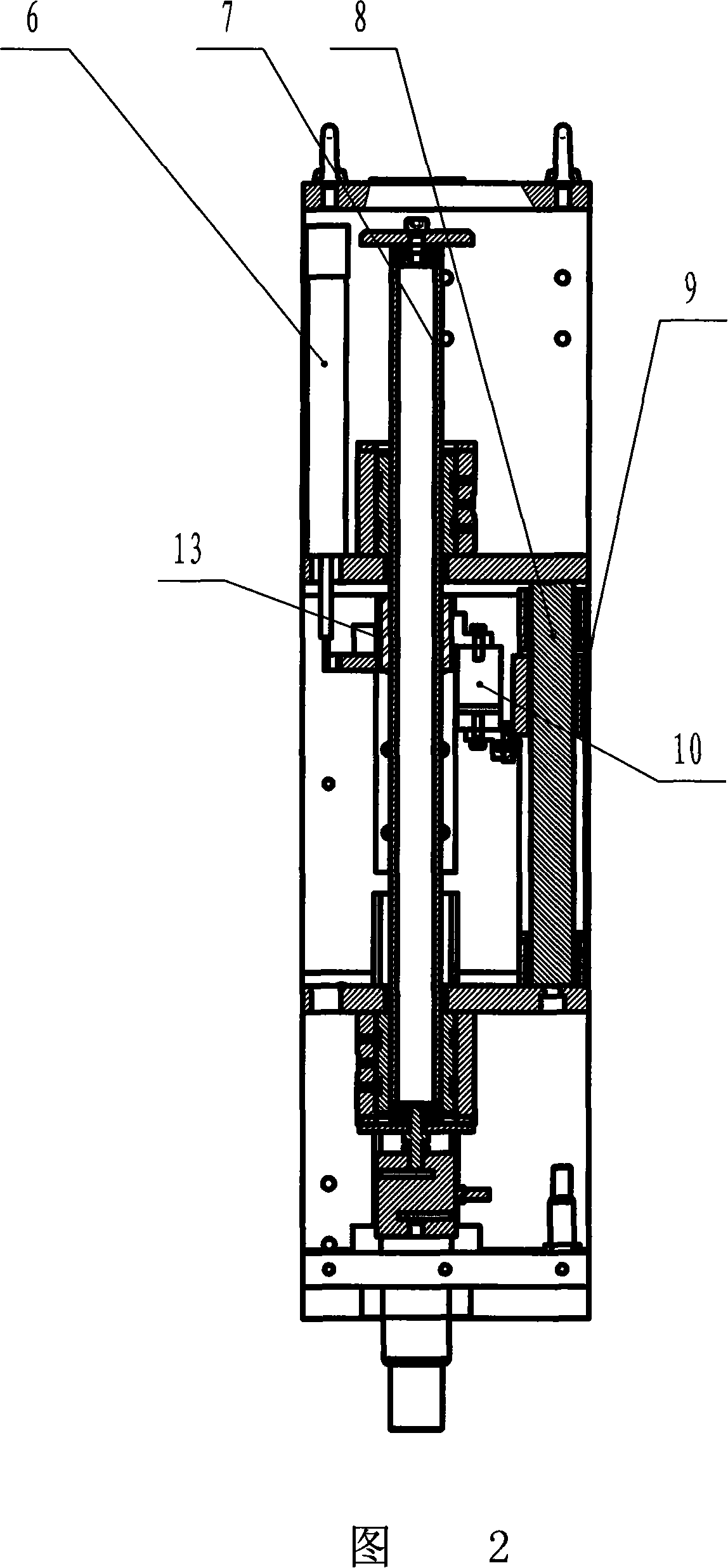

[0017] Referring to Fig. 1 and Fig. 2, an air-floating magnetic dynamic frictionless suspension device, the frictionless suspension device includes a frame 1, an installation frame 2, a moving beam 14, a guide rod 4, a main rod 7, an air flotation system And a magnetic system, the air flotation system includes two frictionless cylinders 17, two identical air storage tanks 19, frictionless cylinders connected to air pipes 18, and a precision pressure relief valve 20; the magnetic system includes long-stroke audio motion Ring 9, exciter iron core 8; the middle part of the frame 1 is fixed with an installation frame 2, and the lower part has a lower mounting plate 22; the installation frame 2 has a top plate and a bottom plate, and two mounting plates are installed on the top plate A small air bearing 3 for the guide rod 4, a large air bearing 5 for installing the main ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com