Lagging mechanism for drawing die and application method

A drawing die and hysteresis technology, which is applied in the field of hysteresis mechanism for drawing dies, can solve problems such as increased stamping costs, additional costs, and crushed parts, and achieves the effects of simple structure, reduced stamping costs, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

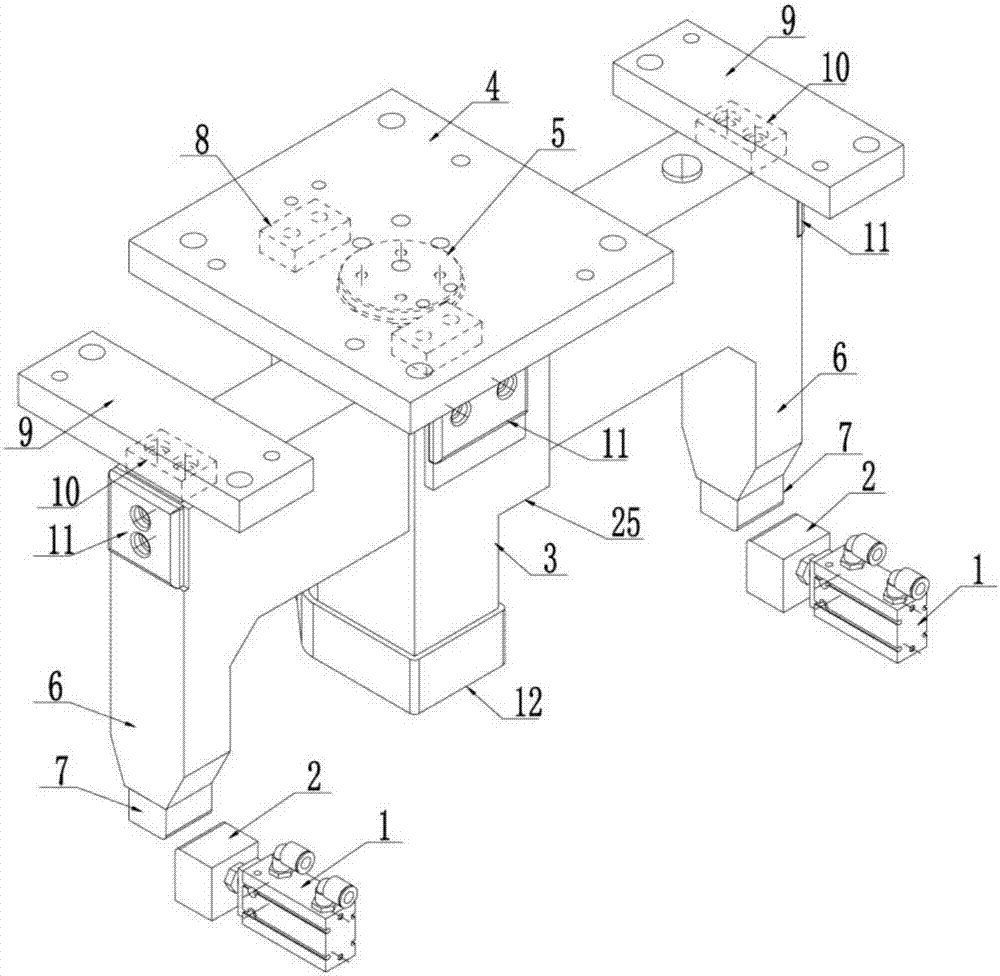

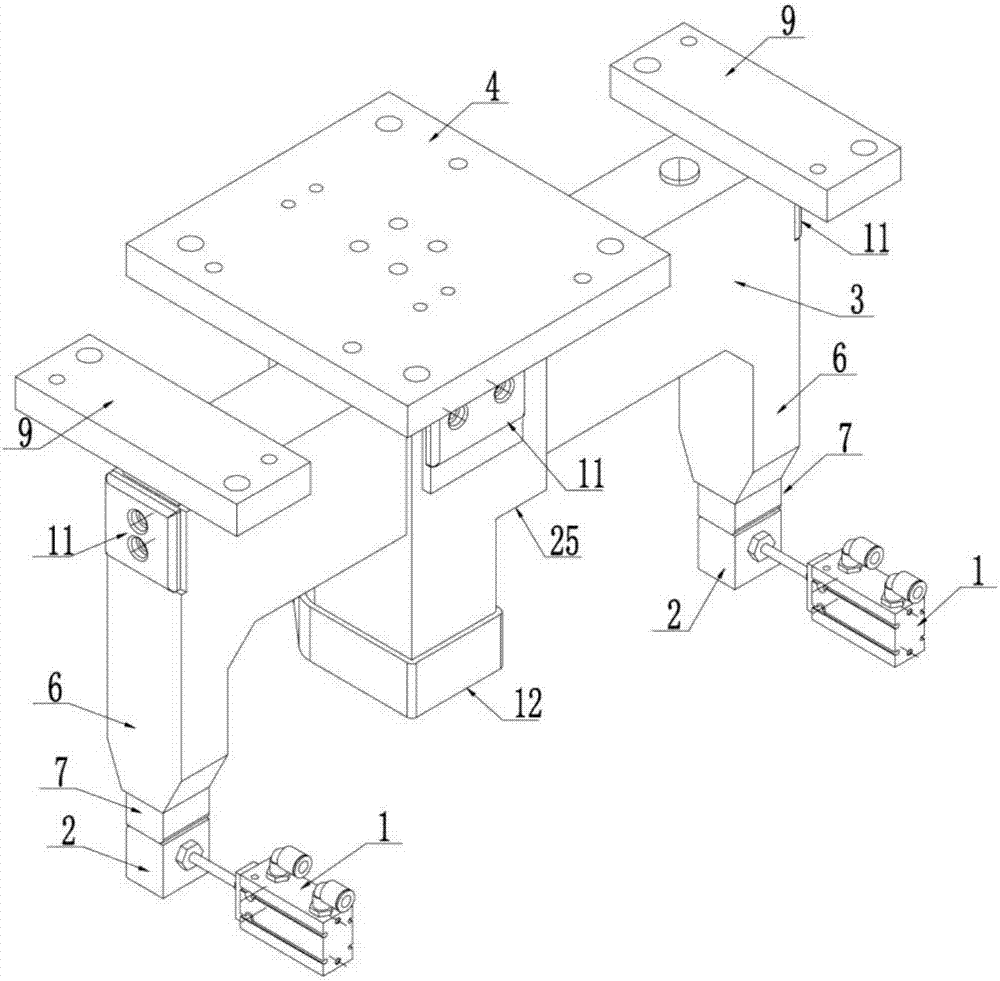

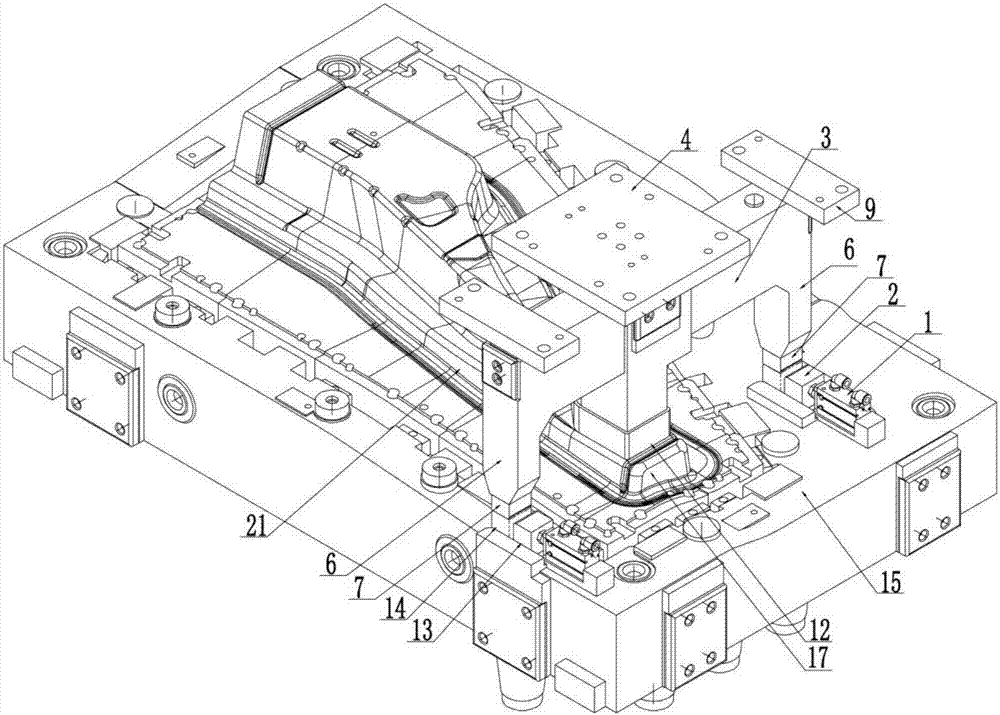

[0045] Such as Figure 1-Figure 6 As shown, a hysteresis mechanism for a drawing die includes two groups of symmetrically arranged hysteresis cylinders 1 and hysteresis pads 2, the hysteresis pads are connected with the piston rods of the hysteresis cylinders, and the cylinder body of the hysteresis cylinders is installed On the blankholder 15, the blankholder is installed on the lower die 17 of the drawing die, and the drawing die also includes an upper die 16 matched with the lower die, and the upper die is provided with a press The material body 3 is provided with a limit cover plate 4 on the upper die above the binder body, and a nitrogen cylinder 5 is arranged on the limit cover plate, and the ejector rod of the nitrogen cylinder presses against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com