Aluminum bottle cap channeling machine

A technology of rolling groove machine and bottle cap, which is applied in capping, packaging, closing and other directions, which can solve the problems of cumbersome operation and high energy consumption, and achieve the effect of increasing work efficiency and reducing time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

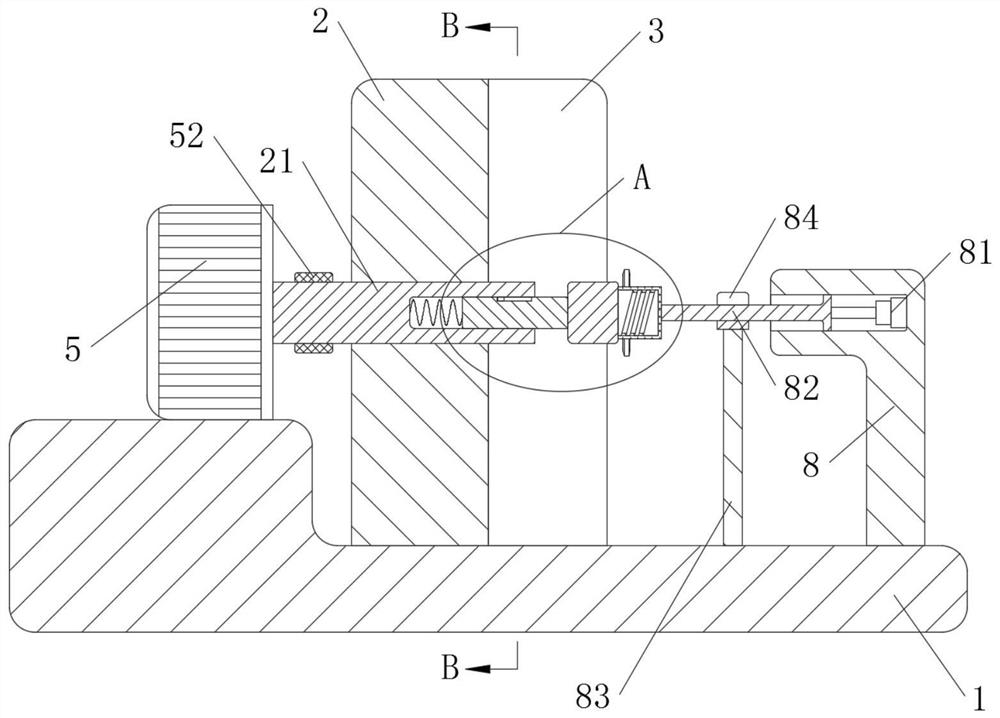

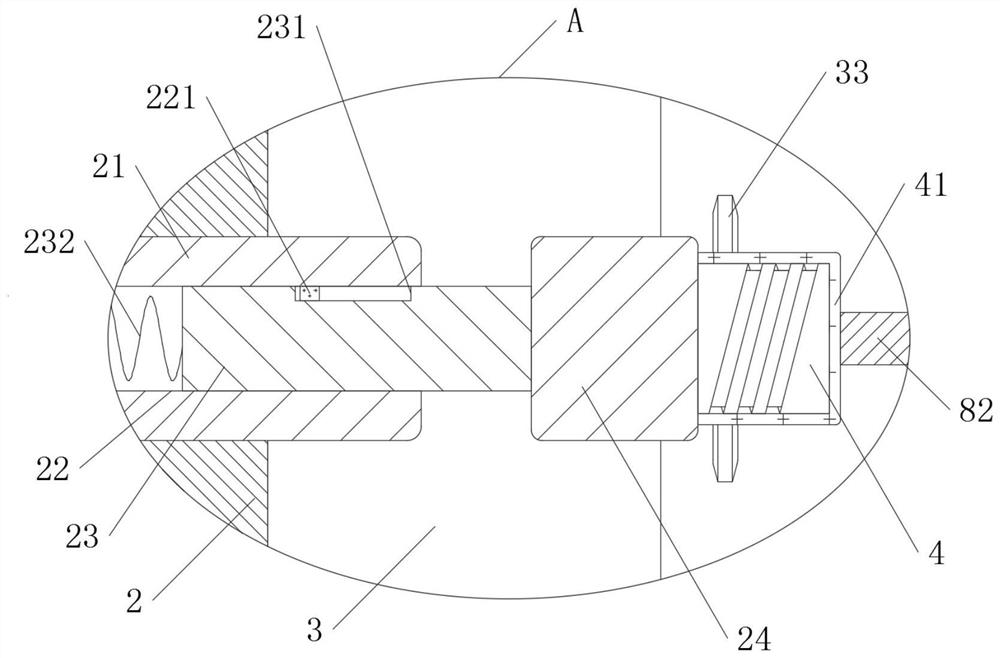

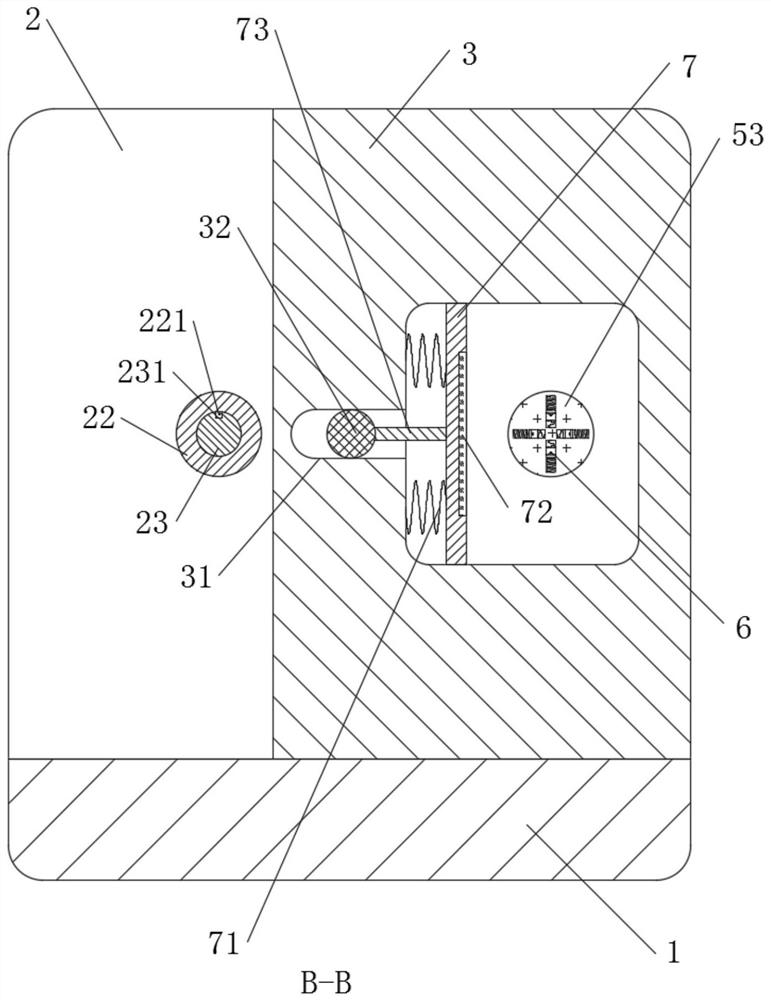

[0026] refer to Figure 1-5 , an aluminum bottle cap rolling machine, including a base 1, the upper end of the base 1 is welded with a first column 2 and a second column 3, the first column 2 and the second column 3 offset each other, and the side wall of the first column 2 runs through Rotationally connected with a first rotating rod 21, the side wall of the first rotating rod 21 is provided with a horizontal groove 22, and the inner wall of the horizontal groove 22 is slidably connected with a sliding rod 23, one end of the sliding rod 23 is located inside the horizontal groove 22, and the other end of the sliding rod 23 is located in the horizontal groove 22. The outside of the horizontal groove 22 is welded with a connecting block 24 on the side wall of the sliding rod 23 outside the horizontal groove 22, and the side wall of the second column 3 is provided with a sliding groove 31, and the inner wall of the sliding groove 31 is slidably connected with a fixed rod 32, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com