Adhesive force automatic monitoring detecting instrument

A technology of automatic monitoring and detector, applied in the direction of instruments, measuring devices, mechanical devices, etc., can solve the problems of inability to observe the change of adhesive force in real time, single electrical control part, low detection accuracy, etc., to achieve low manufacturing cost, movement Flexible and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

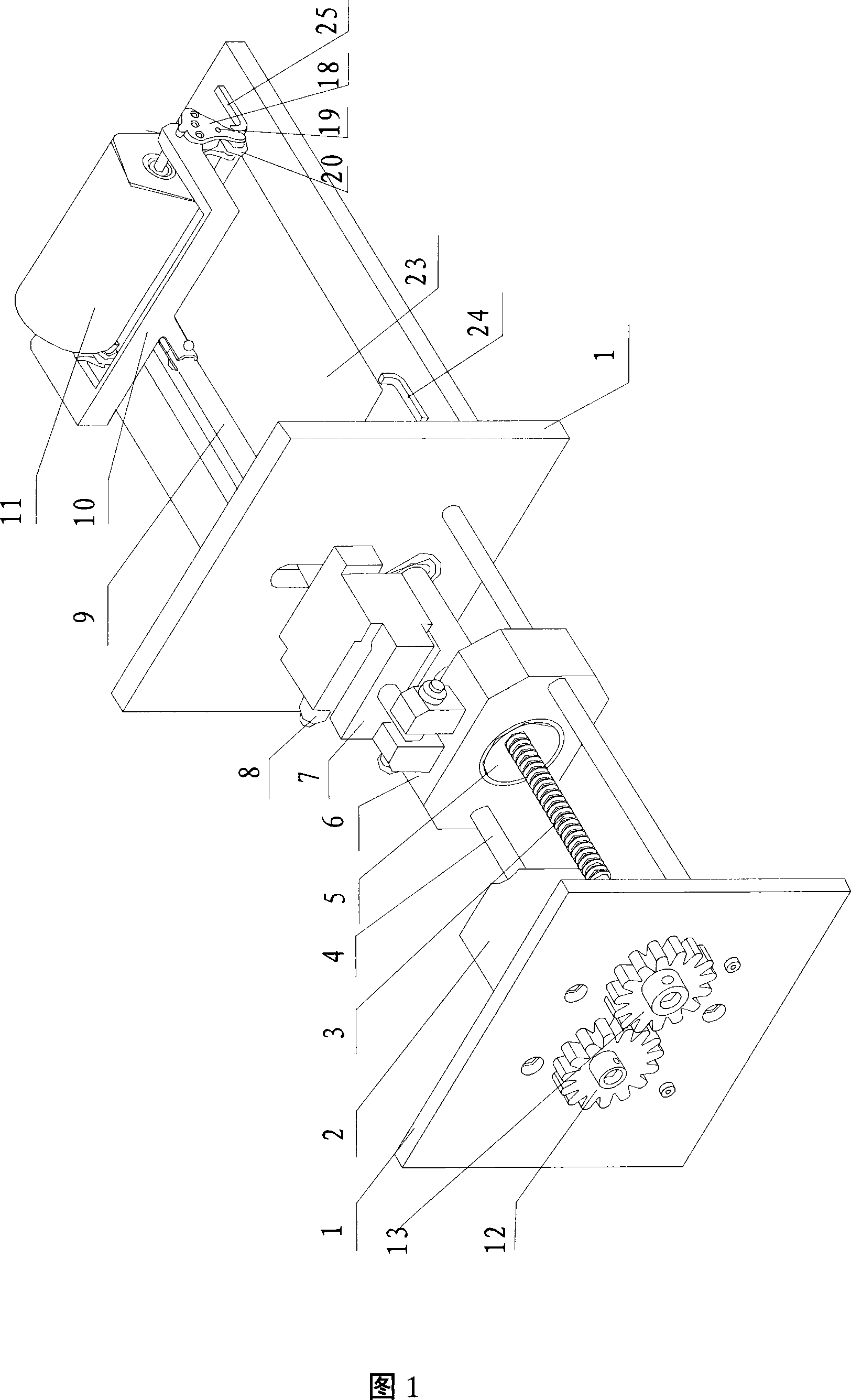

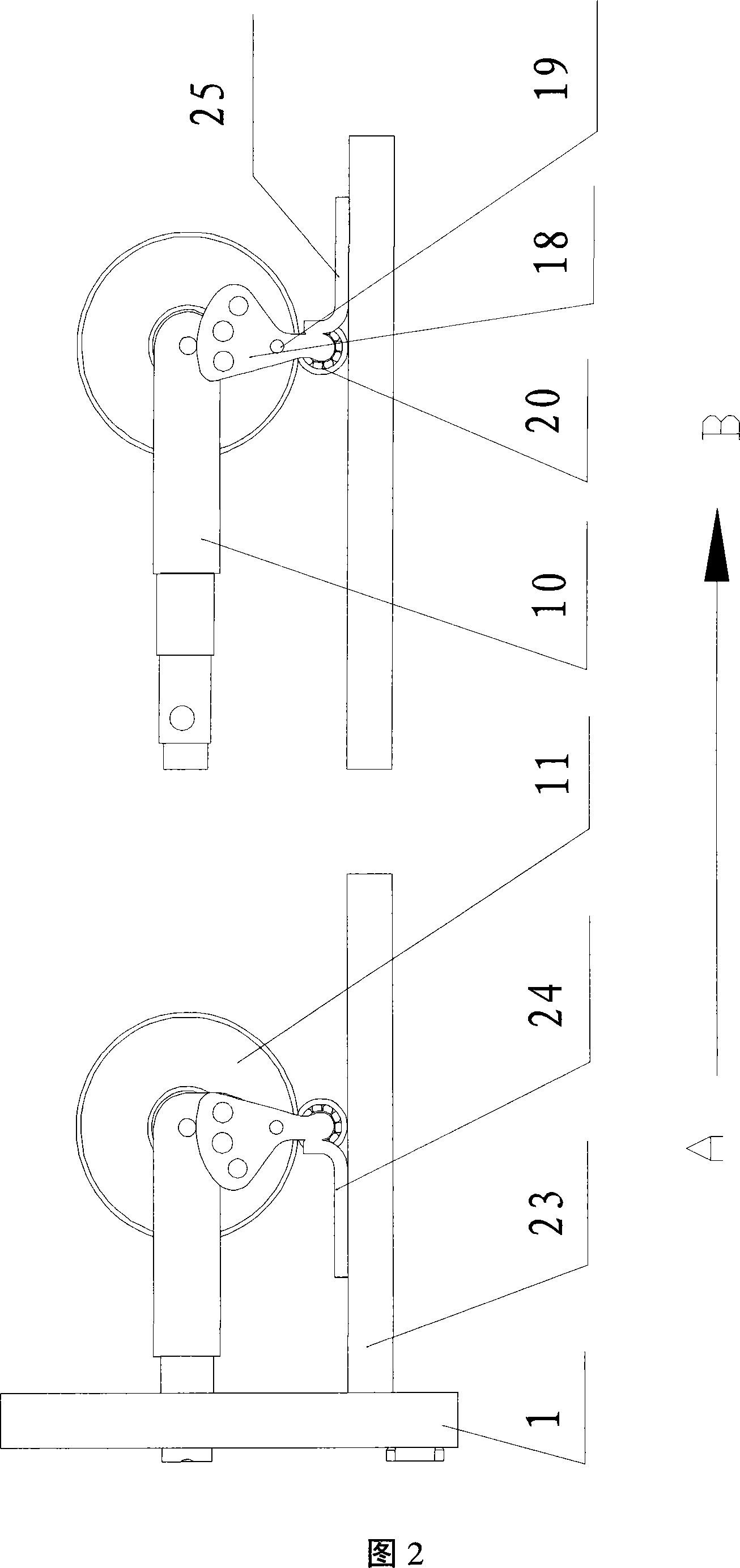

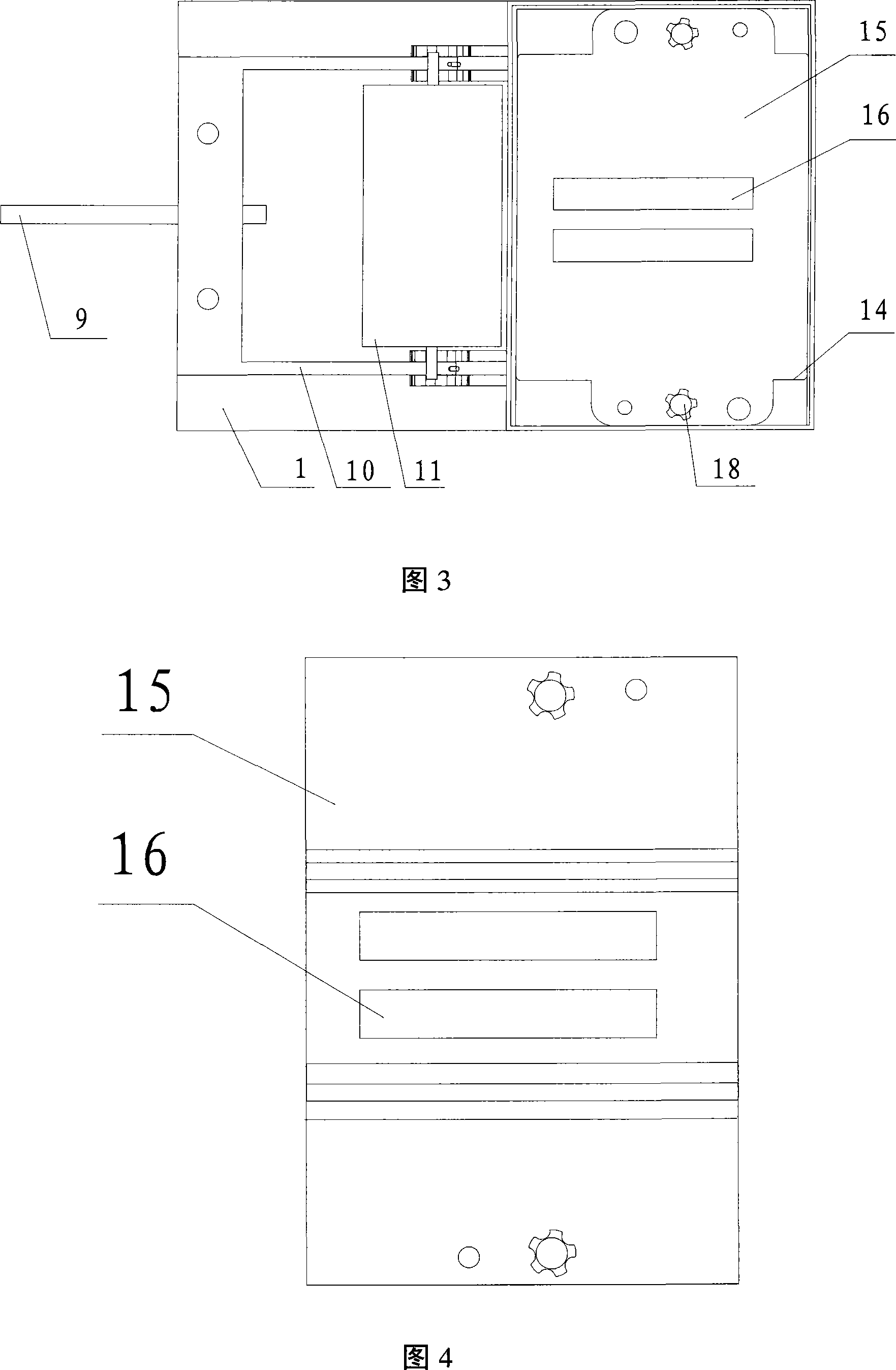

[0026] As shown in accompanying drawings 1 to 5, the mechanical system consists of a frame 1, a stepping motor 2, a gear transmission pair 12, 13, a ball screw 3, a nut 5, a nut bracket 6, a guide rod 4, a tension sensor 8, The detection roller pull bar 9, the detection roller bracket 10, the detection roller 11 detection plate mechanism and the like are composed.

[0027] Detection roller linear reciprocating mechanism

[0028] As shown in Figure 1, the linear reciprocating motion of the detection roller 11 is the mechanical movement link to realize the adhesion test. The movement process is: the motor 2 rotates forward, the driving gear pair 12, 13 drives the ball screw 3, the nut 5 and the detection roller pull rod 9, the detection roller bracket 10, and the machine detection roller 11 start from the initial position along the dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com