High power density motive loop permanent magnetic linear electromotor

A technology of permanent magnet linear motor and high power density, applied in electromechanical devices, electrical components, etc., can solve the problems of large armature reaction, decrease of motor output power, and application of moving coil permanent magnet linear motor. The effect of improving power density and good control characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

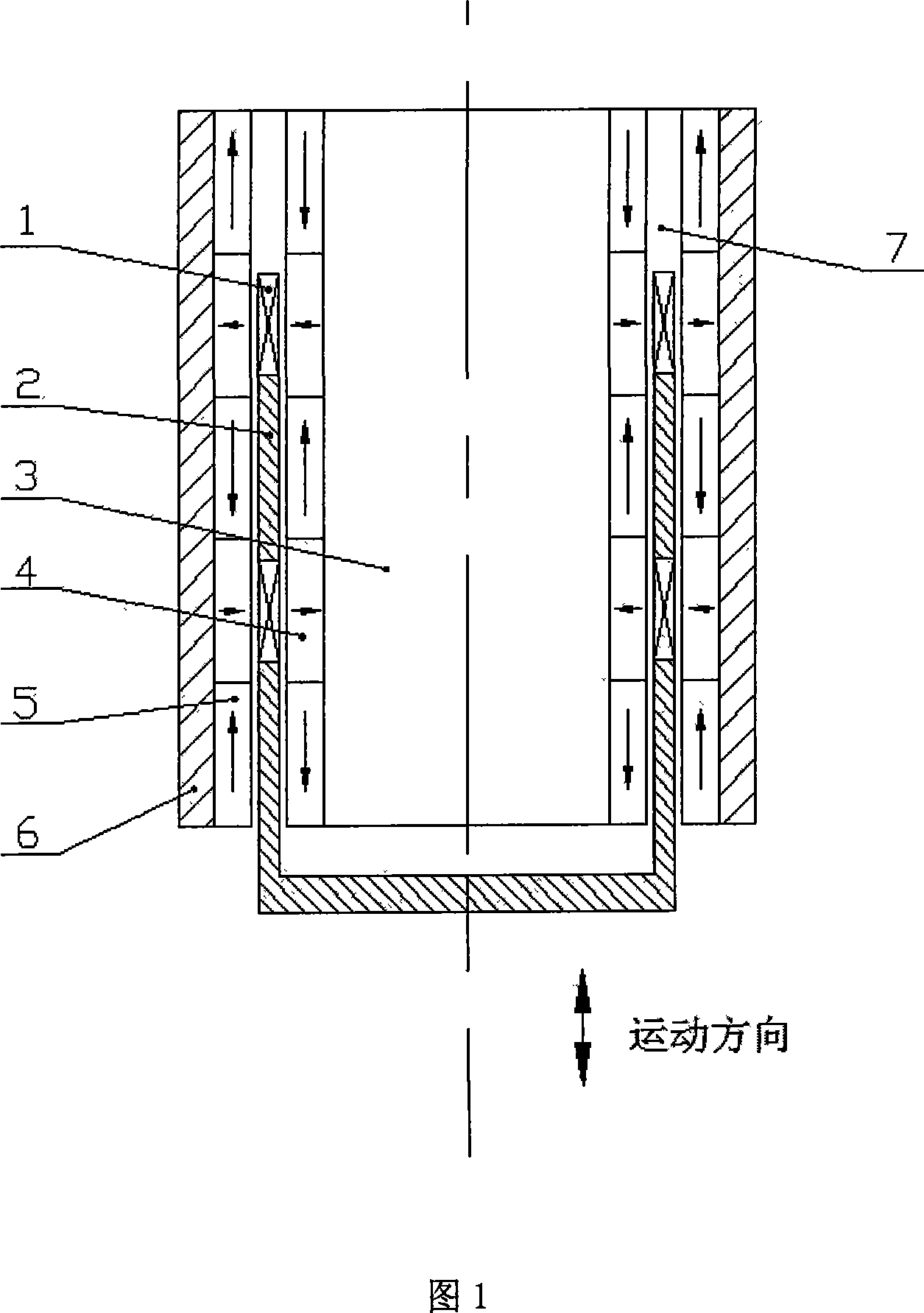

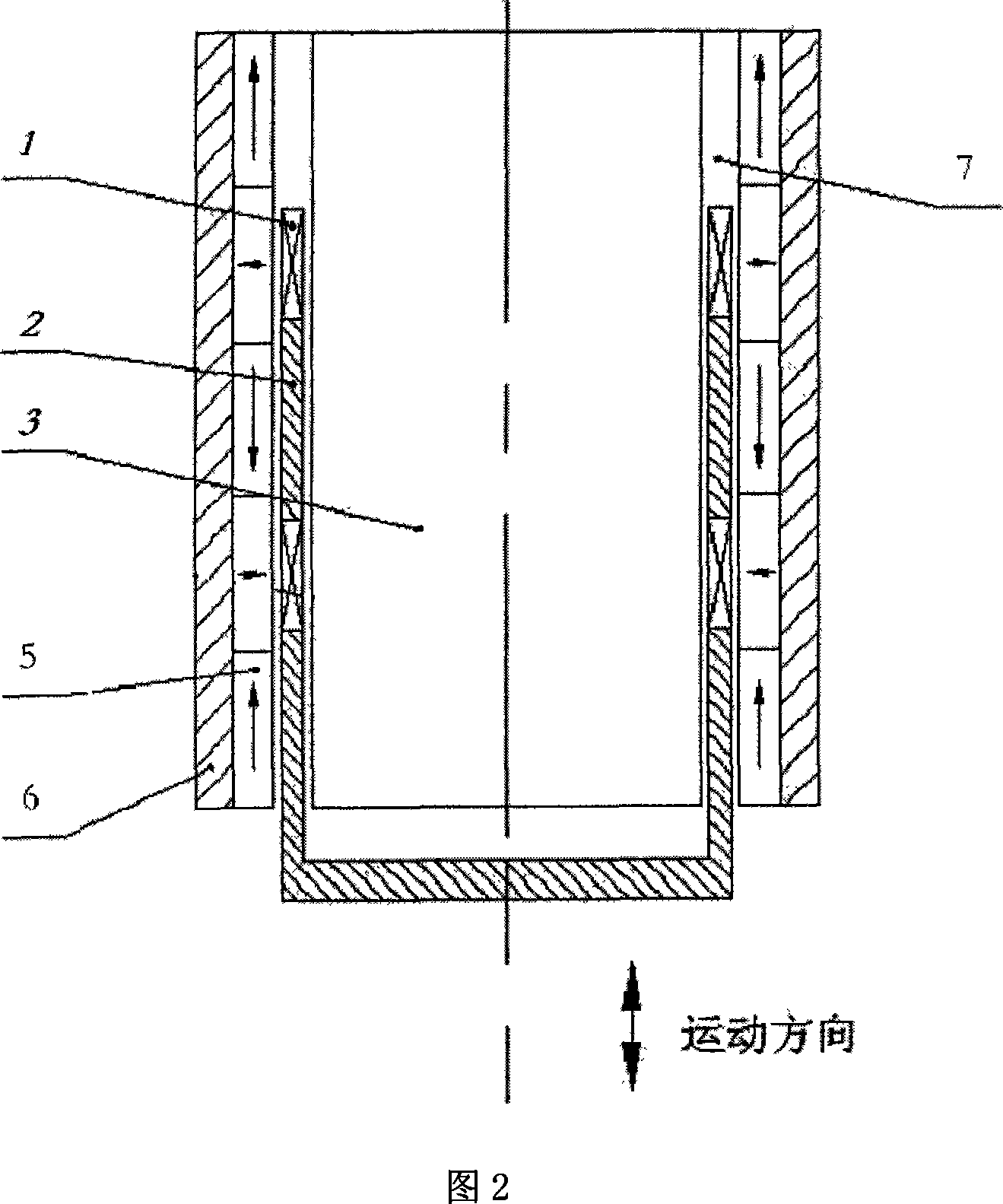

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] Referring to FIG. 1 , the high power density moving coil permanent magnet linear motor of the present invention is applied to the actuator of the intake and exhaust valves in the engine valve train. It consists of coil group 1, coil group frame 2, inner yoke 3, inner permanent magnet 4, outer permanent magnet 5, outer yoke 6, etc. The coil group consists of 2 coils with the same number of turns, fixed in the coil frame , can reciprocate and linearly move in the air gap 7 between the inner permanent magnet and the outer permanent magnet. The winding directions of the two coils of the coil group are opposite. The armature reactions generated by the coils with different winding directions can cancel each other to a certain extent, so that the armature reactions can be effectively reduced. Both the inner permanent magnet group and the outer permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com