Leak indicator comprising a sniffer probe

A technology of leak detection and gas sensor, which is applied in the field of leak detectors and can solve problems such as the adverse effects of the minimum leak rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

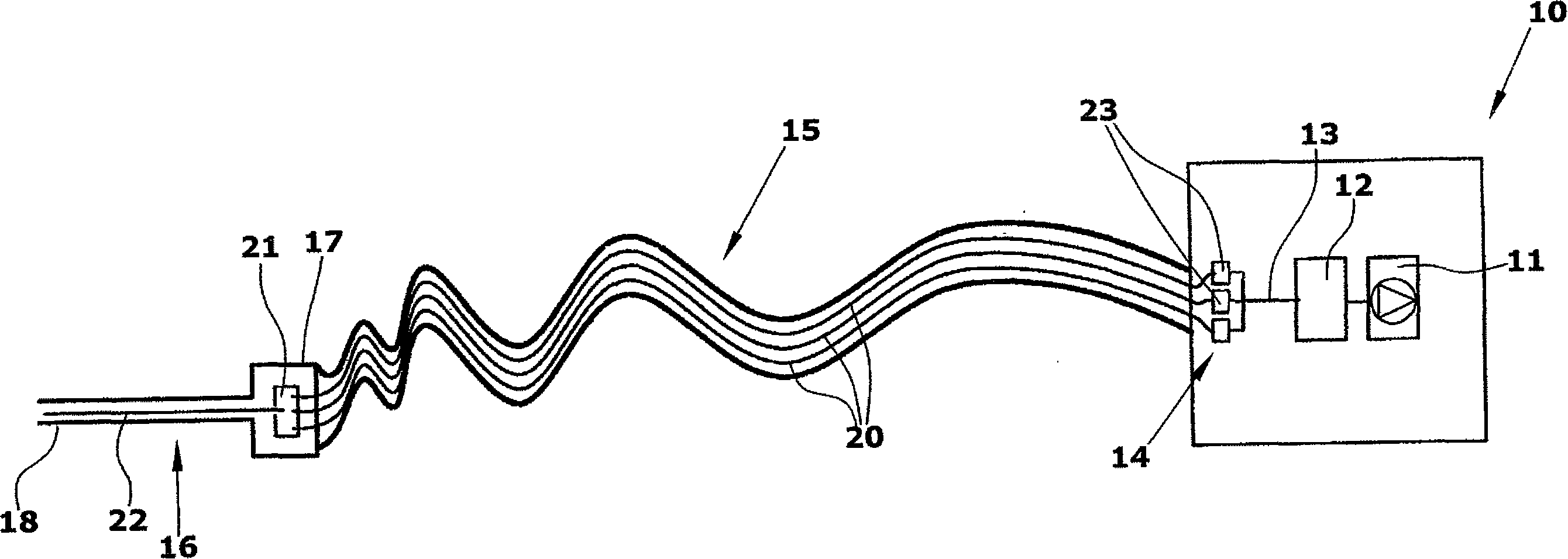

[0020] The leak detector comprises a main device 10 provided with parts that do not have to move during leak testing. The main device 10 is configured as a table-mounted or floor-mounted device. It mainly includes a vacuum pump 11 and a test gas sensor 12 . Mass spectrometers or infrared gas analyzers can be used to test gas sensors. The vacuum pump 11 sucks air through the test gas sensor 12 . The inlet 13 of the test gas detector is connected to a flexible hose line 15 via a valve arrangement 14 . A hose line several meters long extends to the sniffing probe 16 . The sniffer probe 16 is a hand-held device comprising a handle 17 and a sniffer line 18 . The sniffer probe can be designed in the shape of a pistol.

[0021] The hose line 15 comprises a plurality of capillaries 20 which are connected to a line box 21 in the sniffer probe 16 . The line box 21 has a cavity into which an inlet line 22 extending through the sniffing line 18 opens. Inlet line 22 branches in line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com