Process flow of the full-automatic ultra-high temperature sterilization machine

A technology of ultra-high temperature sterilization and process flow, which is applied in the field of process flow of automatic ultra-high temperature sterilizers, can solve the problems of unreasonable design of sterilization process, unsatisfactory degree of automation, and high energy consumption of equipment, so as to expand milk consumption without The effect of high bacterial reliability and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

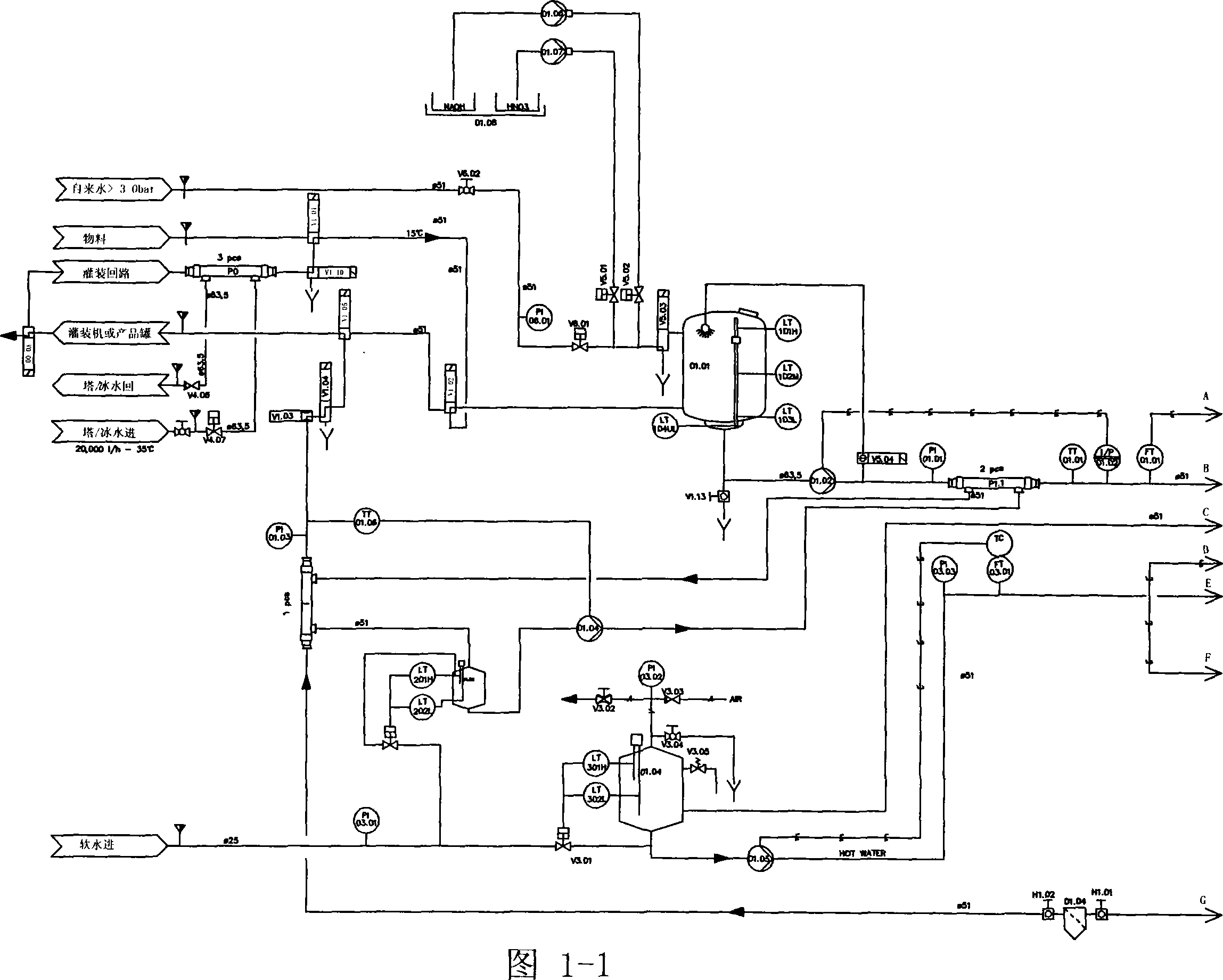

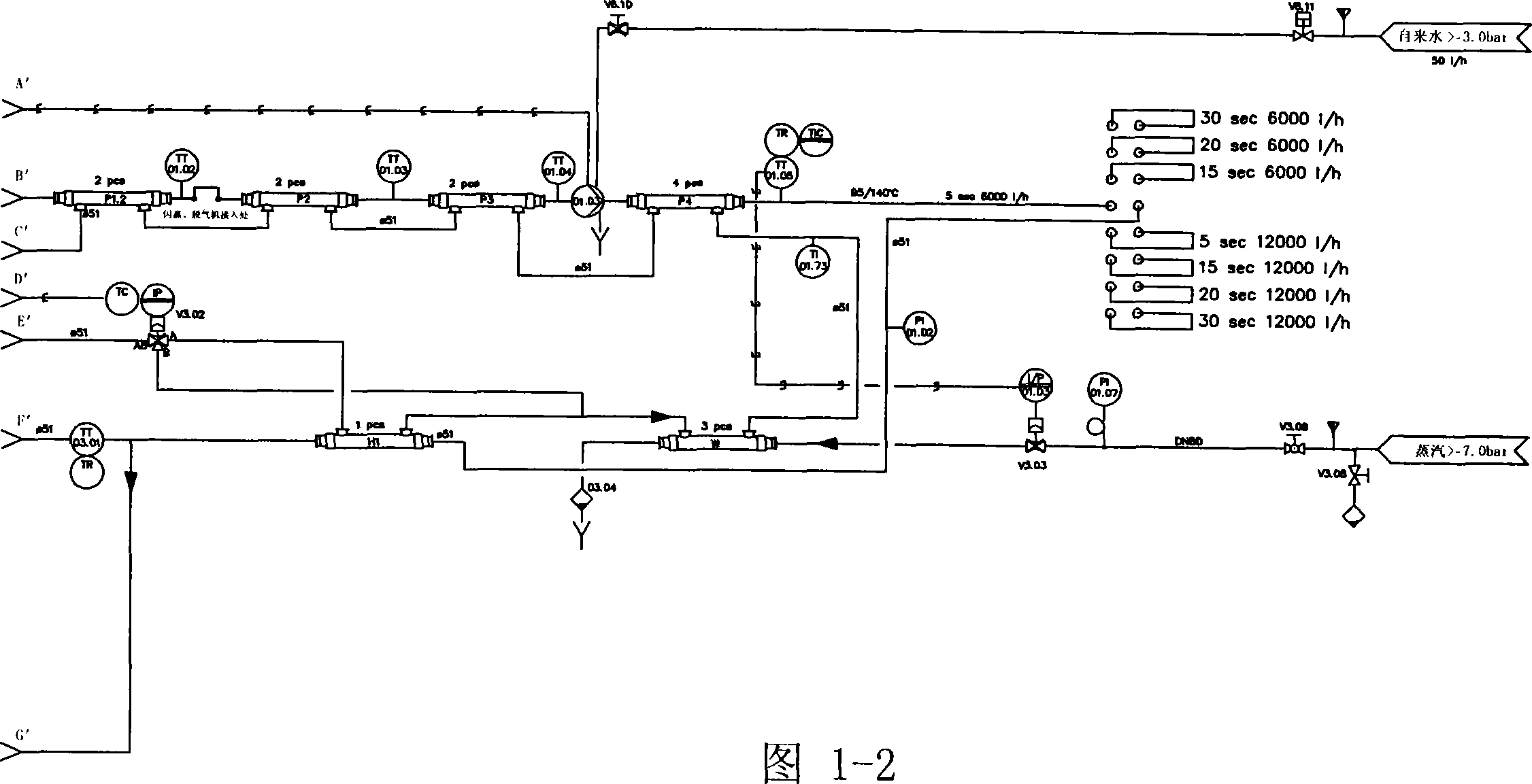

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0023] The invention is suitable for processing and filling beverages such as milk and fruit juice. The process flow is the same during processing, but the temperature of the sterilization process can be slightly adjusted according to actual needs.

[0024] As shown in Figure 1.

[0025] The present invention includes a balance tank 01.01 with four liquid level sensors LT101H, LT102M, LT103L, and LT104UL. When the material liquid level reaches the sensor LT101H, the system stops feeding the balance tank 01.01. When the material liquid level reaches the sensor LT102M , the system starts to feed the balance tank 01.01. When the material liquid level reaches the sensor LT103L, the system starts to drain the balance tank 01.01. When the material liquid level reaches the sensor LT104UL, the system stops working to protect the equipment in the system.

[0026] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com