Curtain wall jointing apparatus

A technology for connecting devices and curtain walls, applied in the direction of walls, building components, buildings, etc., can solve the problems of increasing labor intensity, hidden dangers, and heavy plate plates, reducing the consumption of materials and labor, strong absorption and displacement ability, The effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

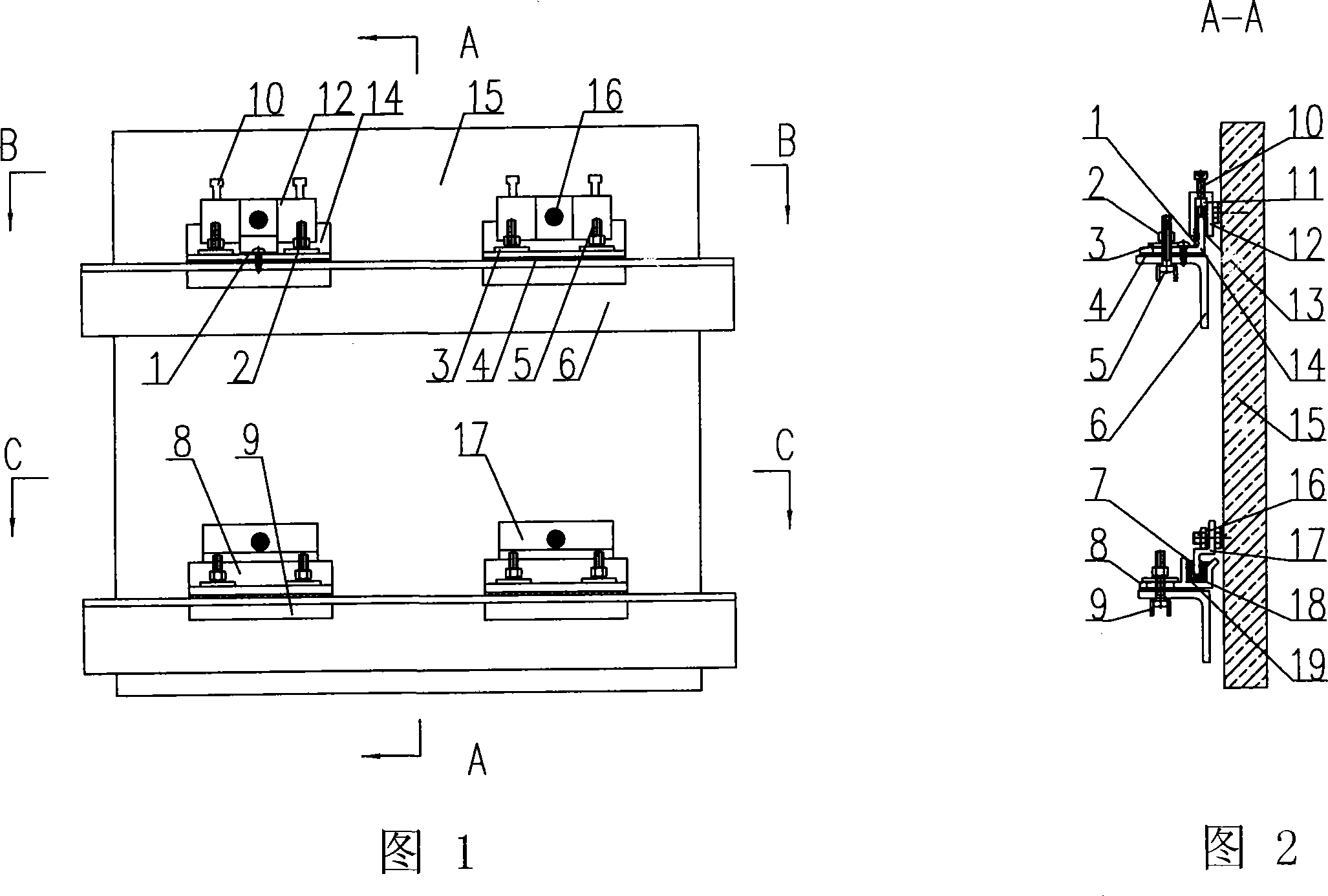

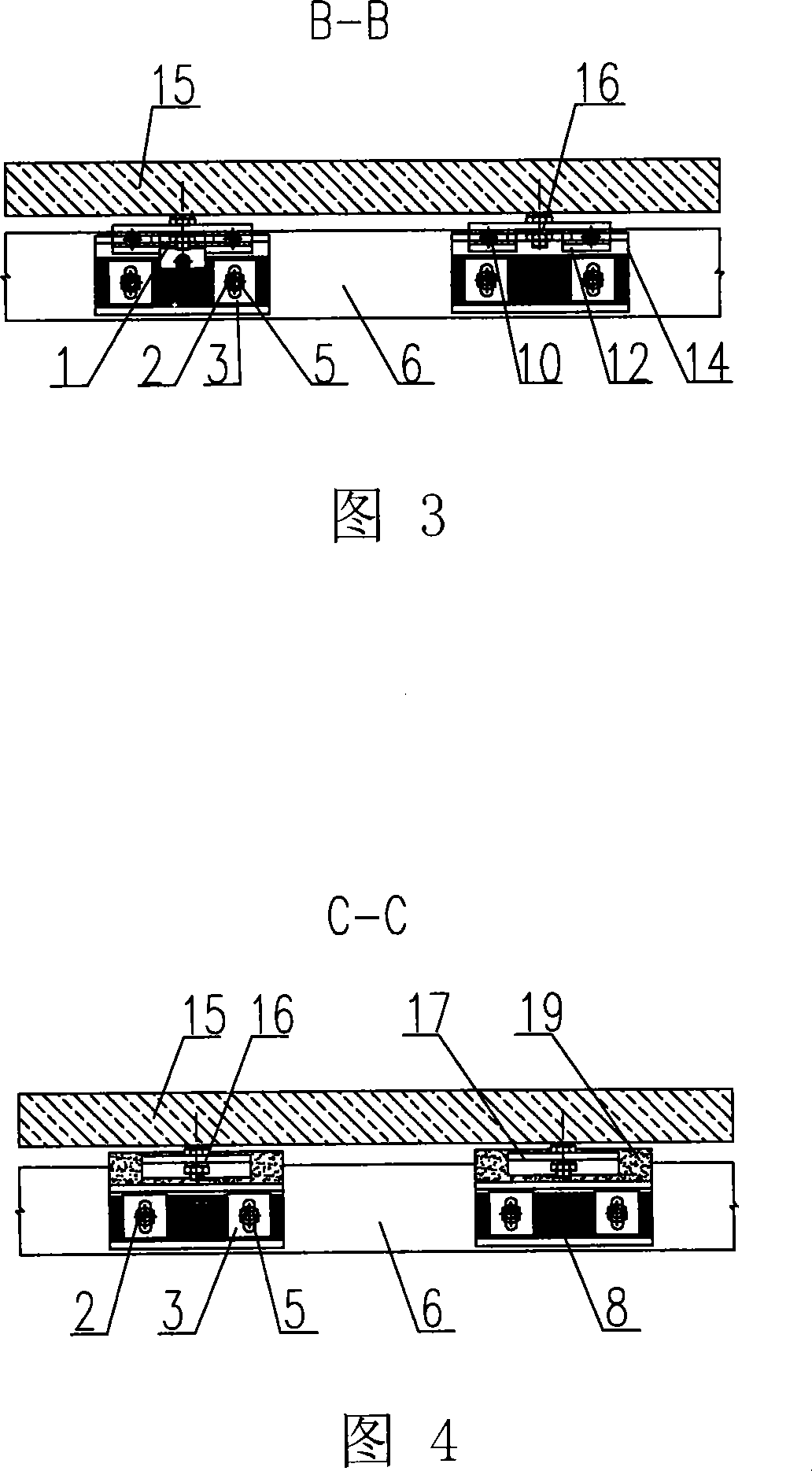

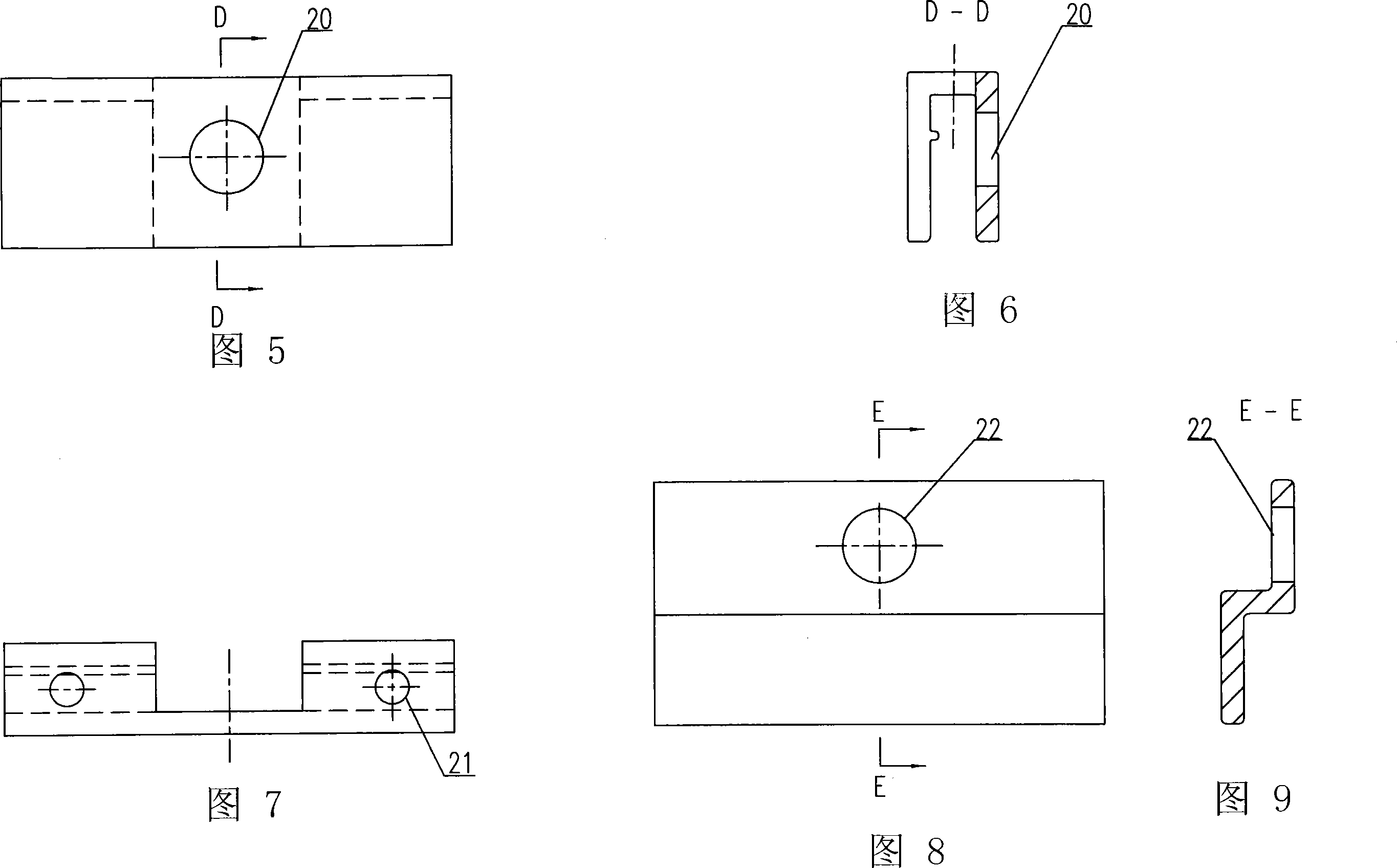

[0028] The specific structure of the present invention will be described in detail according to Figs. 1-16. The device is mainly used in the connection structure of the curtain wall of the back bolt type non-transparent board. It includes a pendant fixed on the preset expansion bolt 16 of the plate plate 15, a supporting plate connected to the keel 6 of the curtain wall structure by using the fastening bolt 5 and the stop pad 9, the positioning tooth plate 3, the spacer 4 and other parts. Wherein the hanger includes an upper hanger 12 and a lower hanger 17, and the supporting plate includes an upper supporting plate 14 and a lower supporting plate 8. In this embodiment, there are four preset expansion bolts 16 on the back of each board plate 15 . Four preset expansion bolts 16 are divided into two rows, left and right, and two preset expansion bolts 16 of the upper row are respectively connected with an upper pendant 12, and the structure of the upper pendant 12 is as shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com