Remote-control detonation control method of industry electric cap

A technology of remote control detonation and control method, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as the inability to guarantee the synchronous detonation of electric detonators, and achieve the problem of low delay time accuracy, easy installation, and network connection. complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

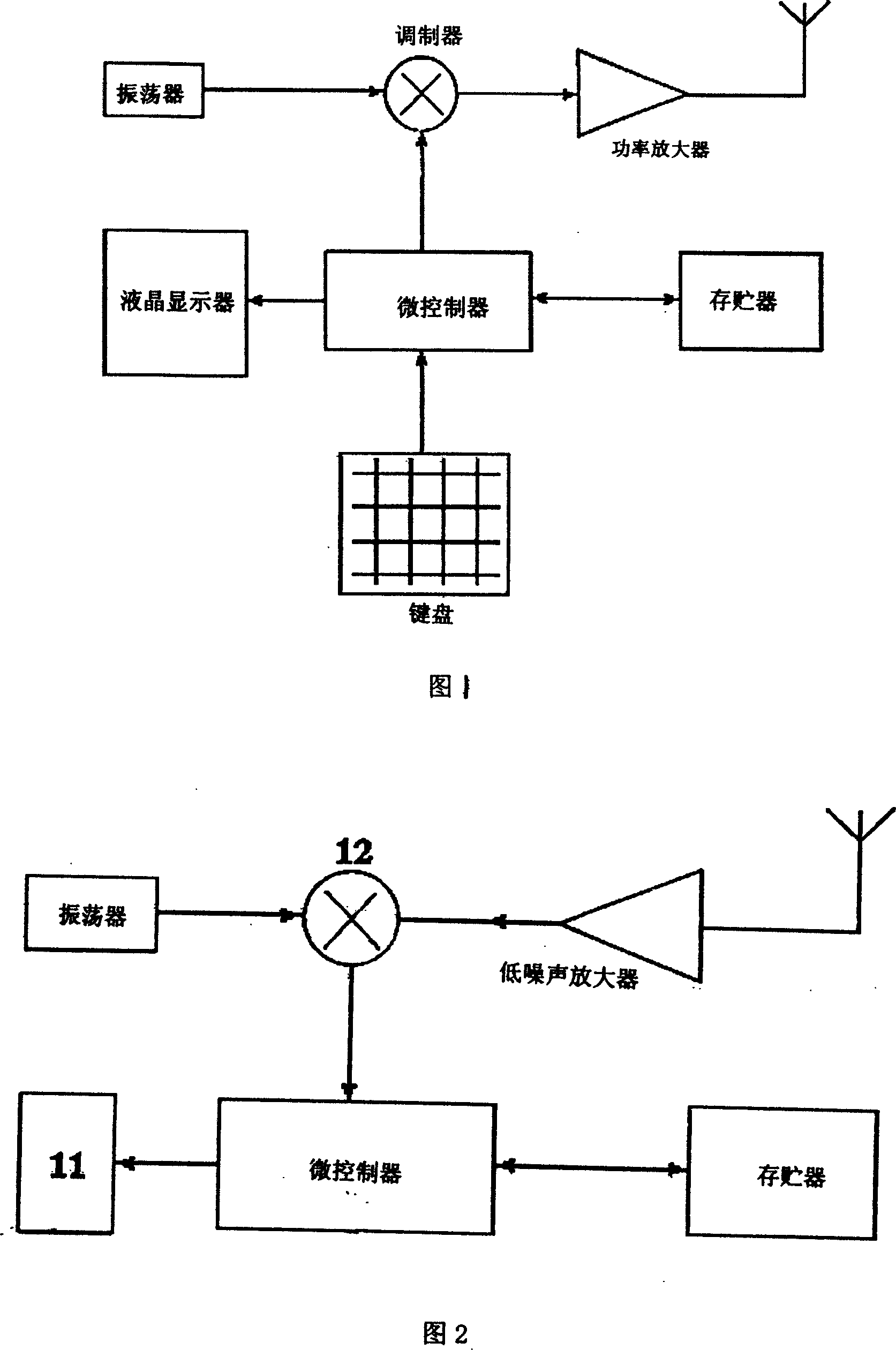

[0013] The remote detonation control method of industrial electric detonators, the transmitter transmits wireless detonation signals, and the signal processing device connected with the controlled industrial electric detonators receives, processes, judges the wireless detonation signals and generates corresponding signals for controlling the controlled industrial electric detonators. The output control signal of the transmitter; the wireless detonation signal emitted by the transmitter is composed of a series of information frames with the same frame structure and a certain number. After the signal processing device connected to the controlled industrial electric detonator receives the wireless detonation signal and performs corresponding processing, Judging the frame sequence number information of the received information frame (that is, judging which information frame is received) and calculating the number of subsequent remaining information frames of the received information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com