Double-screw bolt fast-screwing instrument

A technology of double-ended studs and tools, which is used in manufacturing tools, screwdrivers, metal processing, etc., can solve the problems of double-ended studs, inconvenient use, low efficiency, etc., and achieve the effect of reducing transmission friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

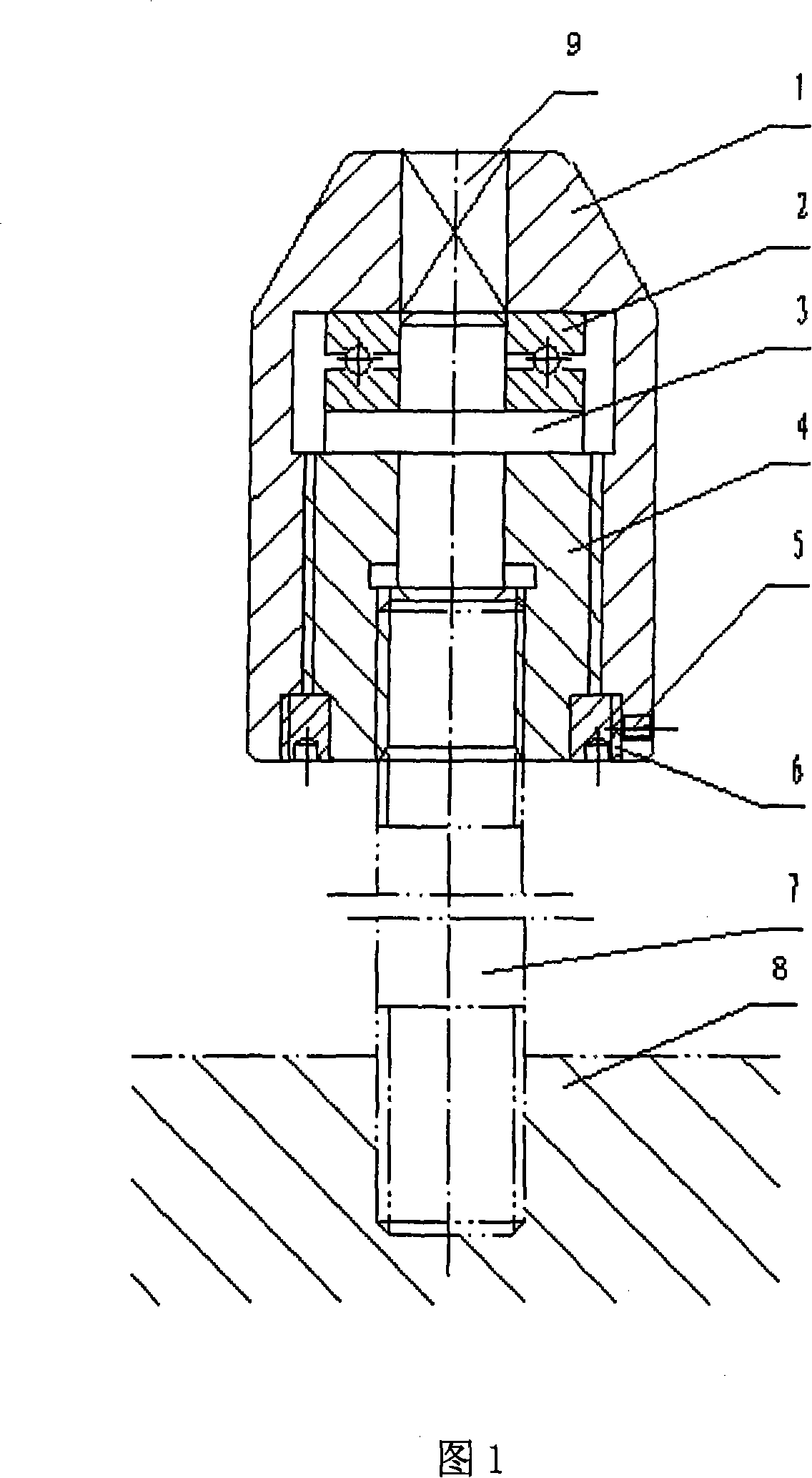

[0008] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0009] Referring to Fig. 1, the present invention includes a housing 1 and a thrust bearing 2, a push rod 3 and a screw sleeve 4 arranged in the housing 1 from top to bottom in sequence, and the upper end of the housing 1 is provided with a square hole 9 that can be connected with an external tool, The thrust bearing 2 is set on the upper end of the ejector rod 3, and put them together in the casing 1. There is a gap of 0.3 mm between the ejector rod 3 and the casing in the axial direction. Press the ejector rod 3 and the thrust bearing 2, and finally limit the position with the nut 6, and fix it with the jacking screw 5.

[0010] The square hole 9 provided at the upper end of the housing 1 is used to connect the air trigger to drive the tool to rotate. It can also be inserted with a square tenon of tools such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com