Inter-tooth transmission structure of speed reducer

A technology of transmission structure and reducer, applied in the direction of gear transmission, transmission, mechanical equipment, etc., can solve the problem of large transmission friction between the teeth of the reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

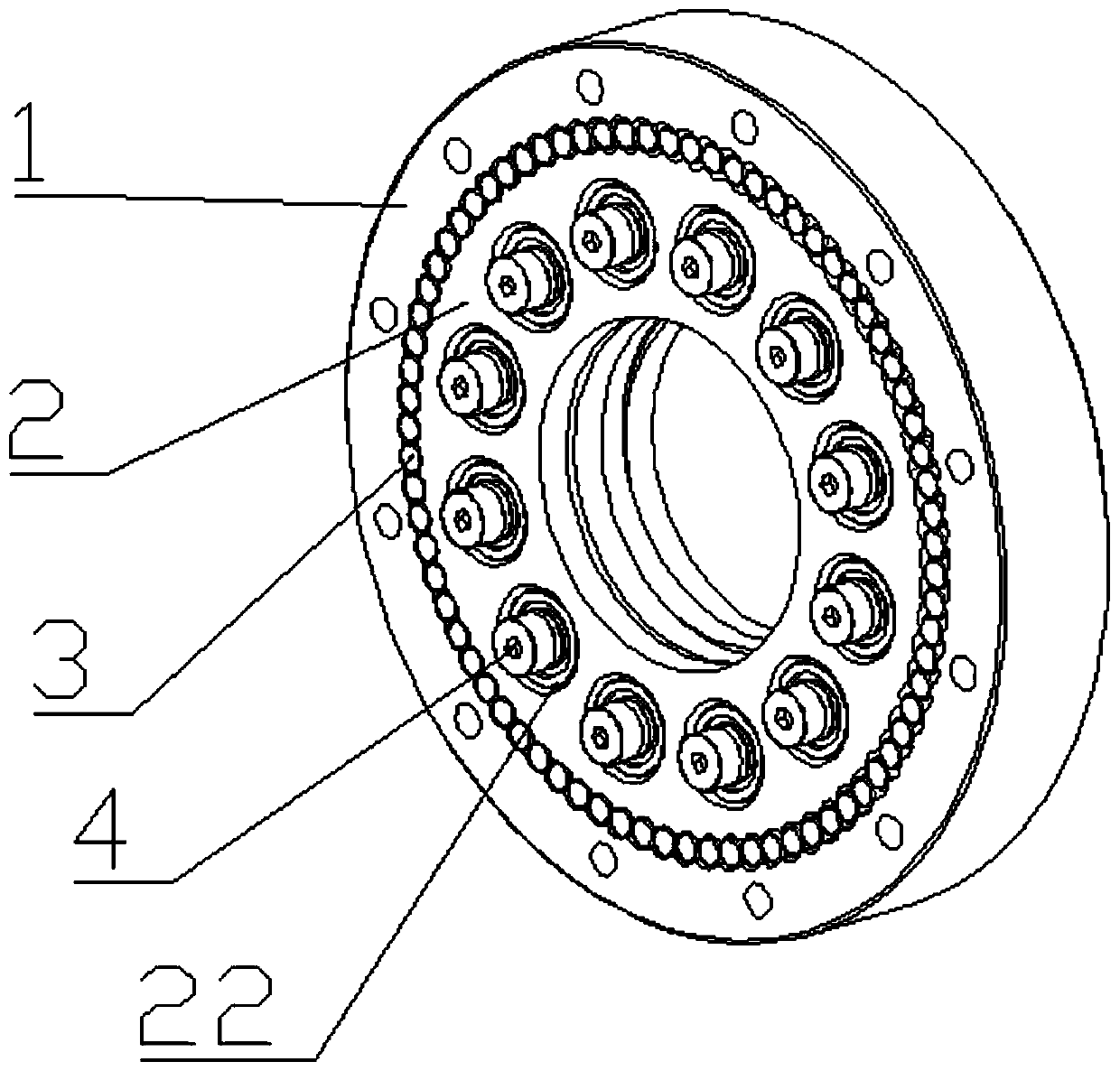

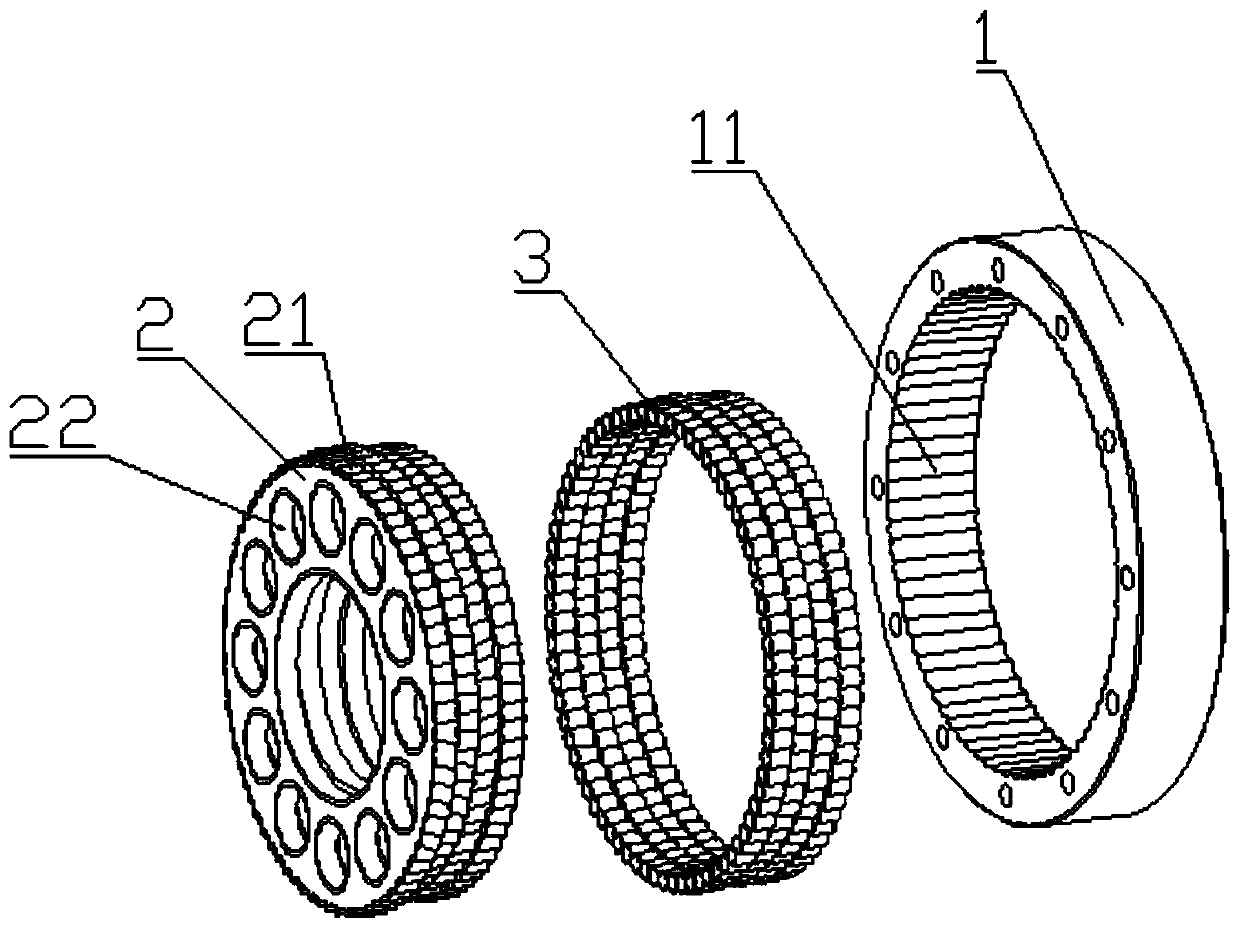

[0023] Embodiment one: if figure 1 and 2 As shown, on the basis of the above technology, the inter-tooth transmission structure also has a transmission structure similar to the cycloid reducer, as follows:

[0024] The inner wheel 2 is selected as a cycloidal wheel, and the outer wheel 1 is selected as a pin-toothed housing.

[0025] In this embodiment, at least three support holes 22 are opened on the inner wheel 2 , and the support holes 22 are supported by ball bearings 4 .

[0026] In this embodiment, the number of said inner wheels 2 is four.

Embodiment 2

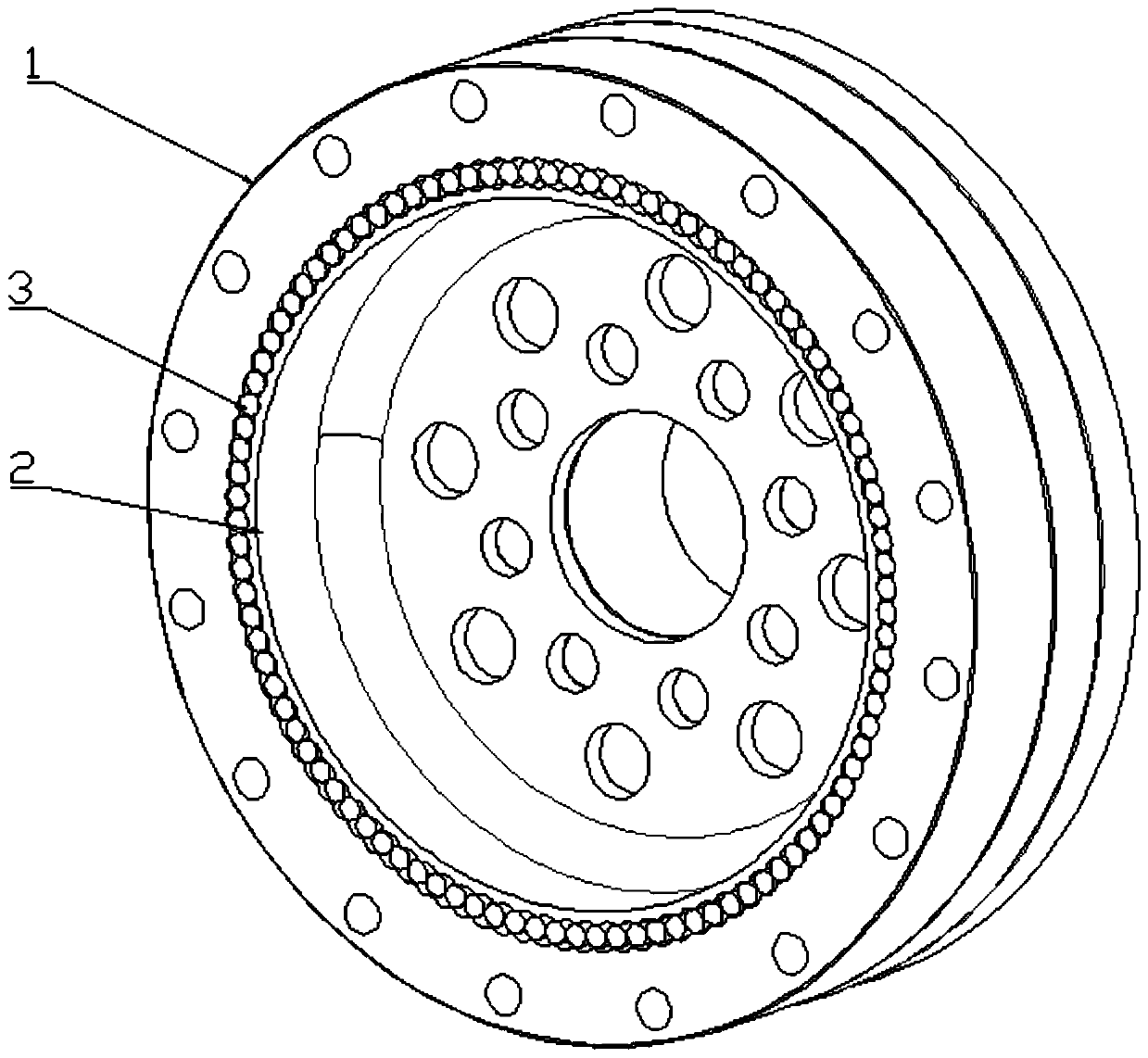

[0027] Embodiment two: if image 3 and 4 As shown, on the basis of the above technology, the inter-gear transmission structure also has a transmission structure similar to a harmonic reducer, specifically as follows: the inner wheel 2 is a flexible gear, and the outer wheel 1 is a rigid gear.

[0028] The rolling element 3 is a cylindrical rolling element. Specifically, the cylindrical rolling element is a rigid cylindrical rolling ball, and the type of the cylindrical rolling element may be a rolling needle, a rolling ball or a miniature rolling bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com