Tu's negative arc gear tooth

A gear tooth, arc-shaped technology, applied in the field of Tu's negative arc-shaped gear teeth, can solve problems such as poor energy saving effect, affecting product service life, gear transmission resistance, etc., and achieve the effect of reducing transmission friction and improving market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

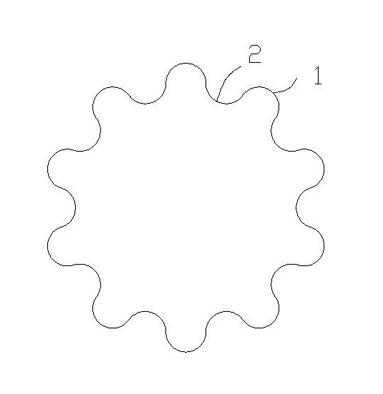

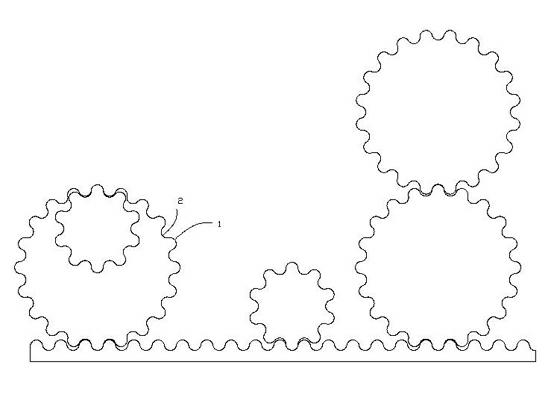

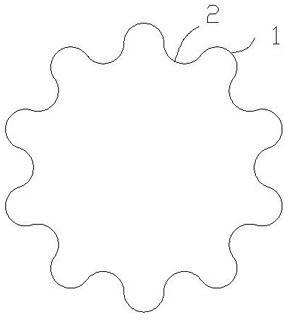

[0009] For an understanding of the invention, see figure 1 , figure 2 , the figure shows the concrete structure of the present invention. Tu's negative arc-shaped gear teeth are composed of tooth top arcs 1 and tooth bottom arcs 2 with the same diameter, which are sequentially interlaced along the gear circumference, and the tooth height and tooth width percentage are between 80% and 90%.

[0010] The arc-shaped gear teeth of the present invention are different from conventional involute tooth gears, and are arc-shaped teeth produced by arc connection. A new design concept of tooth shape is adopted, the design scheme is: the tooth width is greater than the tooth height, the tooth height is smaller than the tooth width, the diameter of the tooth top arc and the tooth bottom arc are the same and the diameter used is greater than the tooth height. The design standard adopts 90%-80% of the tooth width as the tooth height. Those with low speed and high torque can adopt the 95% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com