Microchip testing device

A chip inspection and chip technology, which is applied in the field of microchip inspection devices, can solve problems such as the influence of test results and the spilling of sample liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

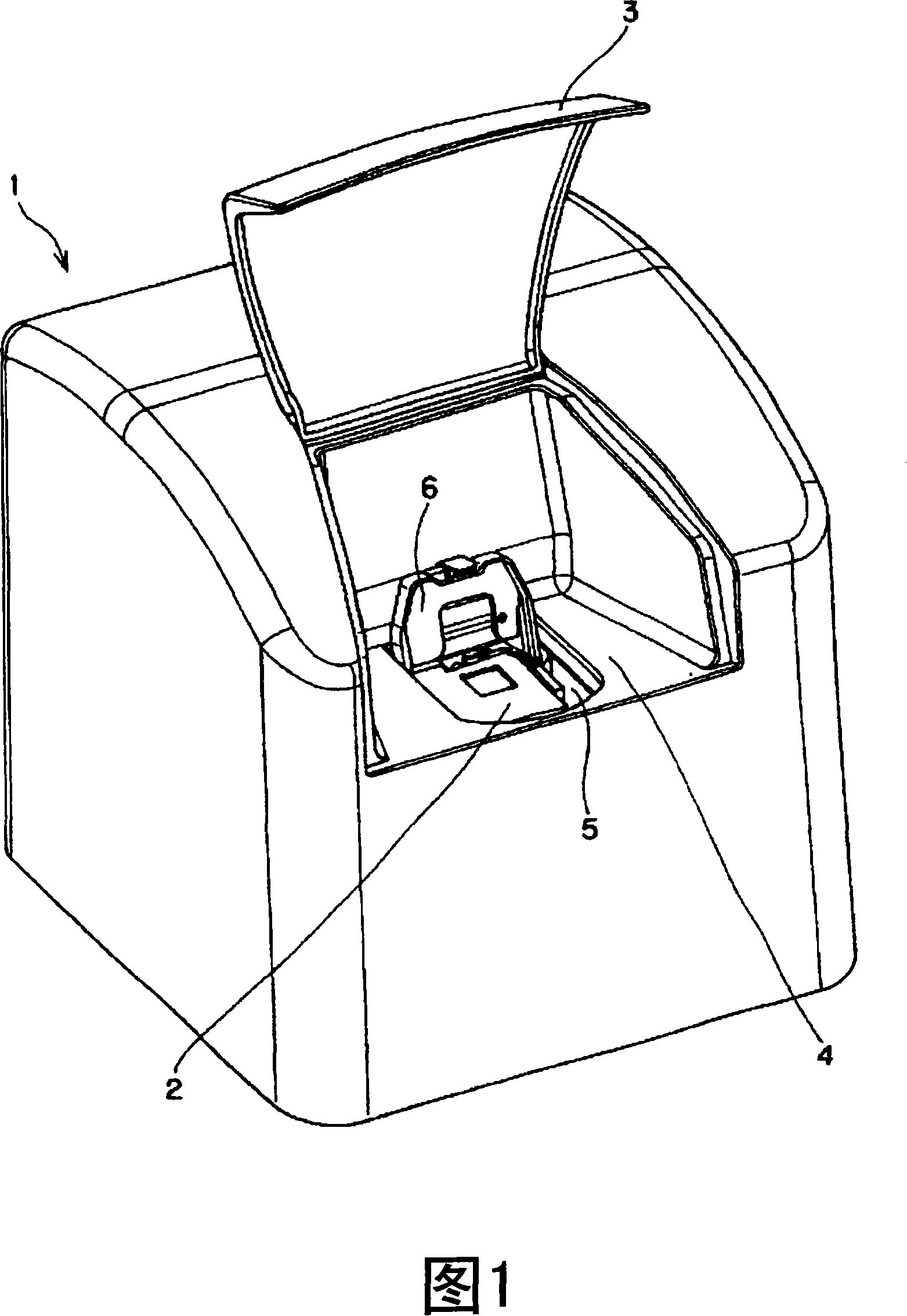

[0039] Fig. 1 is an external view of a microchip inspection device according to the present invention.

[0040] As shown in this figure, the outer surface of the microchip inspection device is constituted by a rectangular parallelepiped frame 1 . The housing 1 is provided with a housing cover 3 for taking and placing the microchip 2, and is fixed openably and closably by a hinge, for example. When assembling the microchip 2 into the microchip inspection apparatus, the frame body cover 3 is opened, the microchip 2 is placed in the chip holder 5 located at the microchip insertion part 4, the cover part 6 is closed to fix it, and the frame is closed. body cover 3.

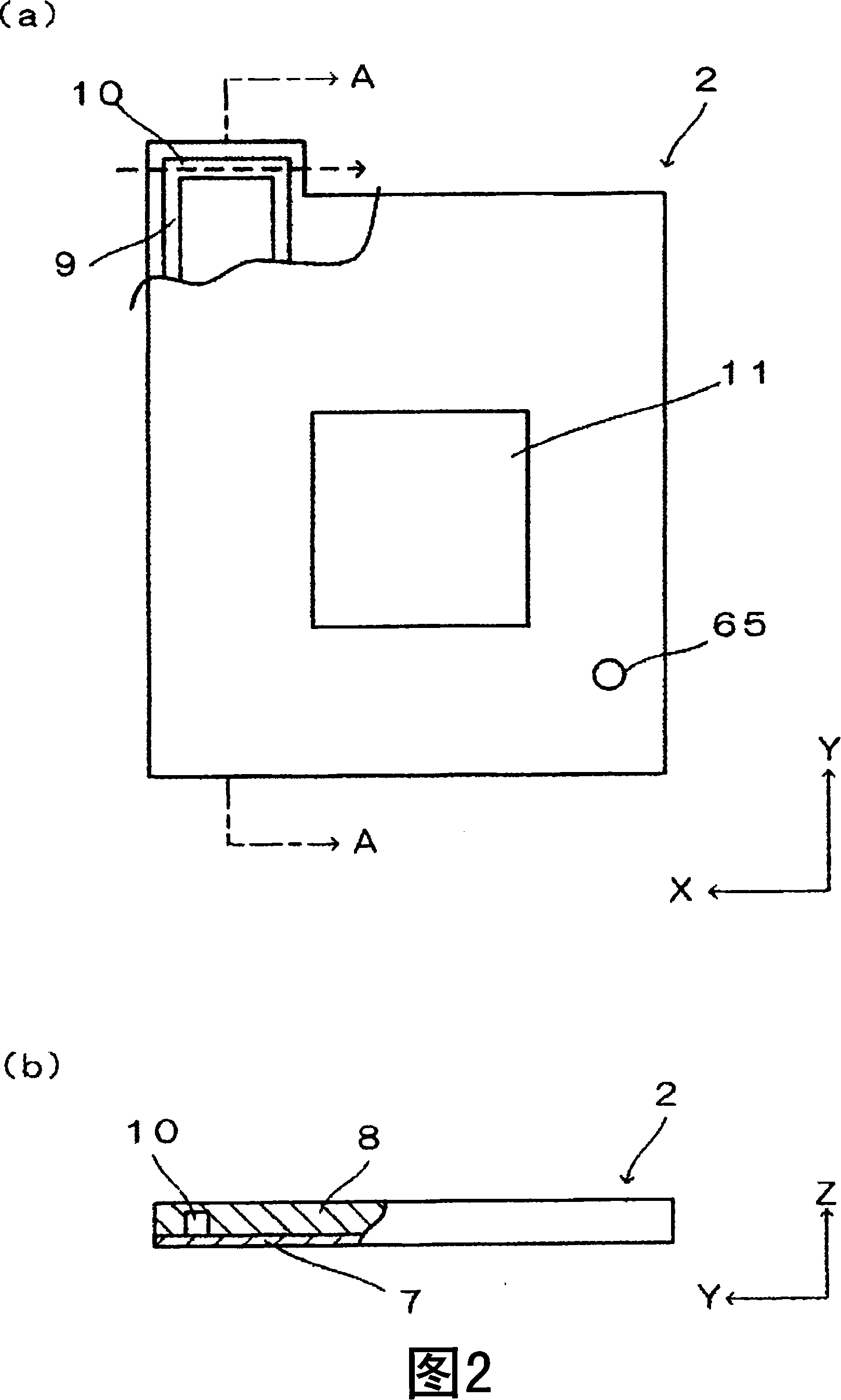

[0041] Fig. 2 (a) is a plan view showing the microchip 2 for single-item inspection contained in the chip holder 5 of the microchip inspection device, and Fig. 2 (b) is an A-A sectional view shown in Fig. 2 (a), that is Shows cross-sectional views in the Y and Z directions.

[0042] As shown in FIG. 2(b), the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com