Washable leather with oil- and water-repellency

An oil- and water-repellent technology, used in leather impregnation, special leather manufacturing, small raw hide/large hide/leather/fur treatment, etc., which can solve problems such as oil resistance and durable dirt removal without teaching durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

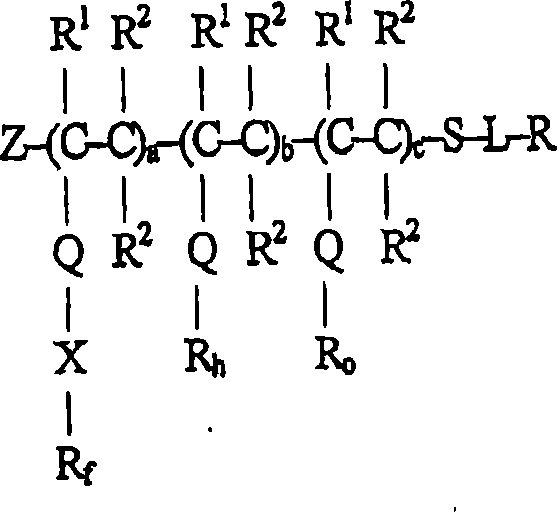

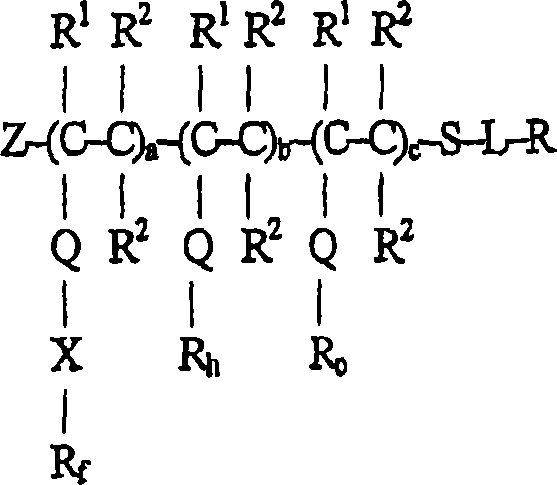

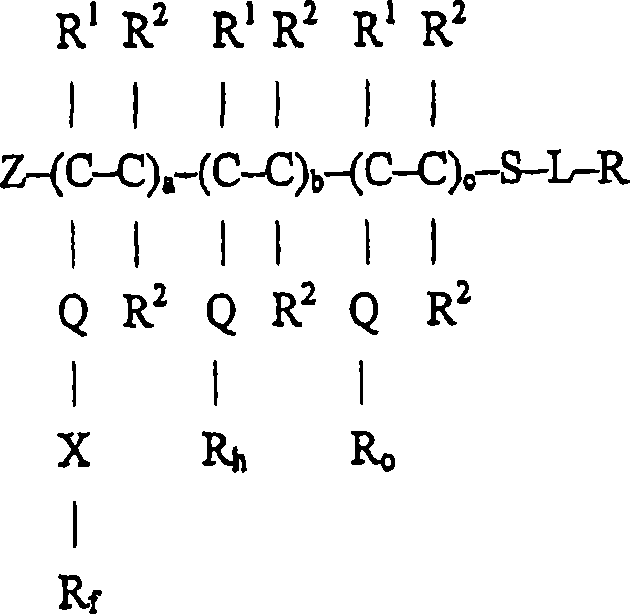

Method used

Image

Examples

Embodiment 1

[0107] The flask was filled with 99.98 g of a solution of 62.7% by weight DESMODUR N-100 (a hexamethylene diisocyanate prepolymer available from Lanxess Corporation, Pittsburgh PA) (320 mmol-NCO calculated) dissolved in methyl isobutyl ketone MIBK, 1.94 g isethionic acid (13 mmol), 16.77 g stearyl alcohol (61 mmol), 16.76 g ISOFOL 18T (61 mmol, available from Sasol North America, Inc., Houston TX) and 57.68 g mixed 1,1,2 , 2-tetrahydroperfluoro-1-alkanol, predominantly C8, C10, C12 and C14 with small amounts of C6, C16 and C18 (available from E.I. Du Pont de Nemours and Company, Wilmington DE, 122 mmol). With agitation, this mass was heated to 48°C and a solution of about 0.027 g dibutyltin dilaurate dissolved in 1-2 mL MIBK was added to the flask. The reaction temperature rose spontaneously to 76°C due to the heat of reaction. The reaction mass was then further heated to 130°C and maintained at this temperature for 21-22 hours. After adding 2.33 g of deionized water to cons...

Embodiment 2

[0109] A mixture of tris-(2-perfluoroalkylethyl) citrates was prepared using a mixture of 2-perfluoroalkylethanols. The mixture of 2-perfluoroalkylethanols is such that in its perfluoroalkyl group CF 3 CF 2 (CF 2 ) k wherein k is 2, 4, 6, 8, 10, 12 and 14 in a weight ratio of about 1 / 33 / 31 / 18 / 8 / 3 / 1, and such mixtures have an average molecular weight of about 452. 2-Perfluoroalkylethanol (4306 kg) was combined with anhydrous citric acid (562 kg) at 70°C + / - 5°C with agitation. Thereafter granular boric acid (2.7 kg) and aqueous phosphorous acid (6.4 kg of a 70% solution) were added as catalysts. The temperature of the reaction mixture was increased to 130°C + / - 5°C over a period of 3-4 hours with agitation. Agitation was continued for 23-24 hours while removing water formed from the reaction between 2-perfluoroalkylethanol and citric acid. When analysis indicated that the esterification was complete, the reaction temperature was lowered to 70-80°C and butyltin trichloride...

Embodiment 3

[0113] The tanning process begins with the wet blue stage as described above and in US Pat. No. 5,972,037. Wash and rinse the wet blue hide. They were then dipped into a water float containing 100% to 150% by weight of wet blue hides and 1% by weight of wet blue hides in sodium formate, with 0.75% by weight of wet blue hides added with sodium acetate as a buffer. After buffering, the hides are washed, dried and refloated in water having at least 100%-150% wet blue weight. Then 6% wet blue hide weight of TERGOTAN MC-N and 4% wet blue hide weight TERGOTAN EFB, each available from Clariant Corporation, Fair Lawn, NJ, were added as property building agents to help build softness into the leather. After the hides were again drained, washed and refloated as before, 4% by weight of wet blue hides of DERMALIX C (also available from Clariant Corp.) was added as a softener. Dyes are then added to achieve the desired color of the finished leather. This is followed by fixative (formic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com