Patents

Literature

42 results about "Tanning tanning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sun tanning or simply tanning is the process whereby skin color is darkened or tanned. It is most often a result of exposure to ultraviolet (UV) radiation from sunlight or from artificial sources, such as a tanning lamp found in indoor tanning beds.

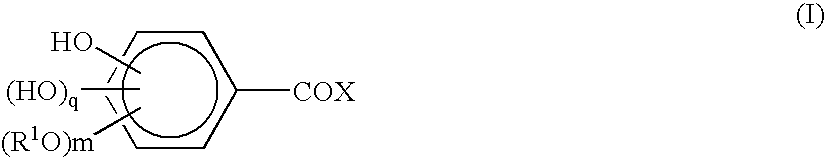

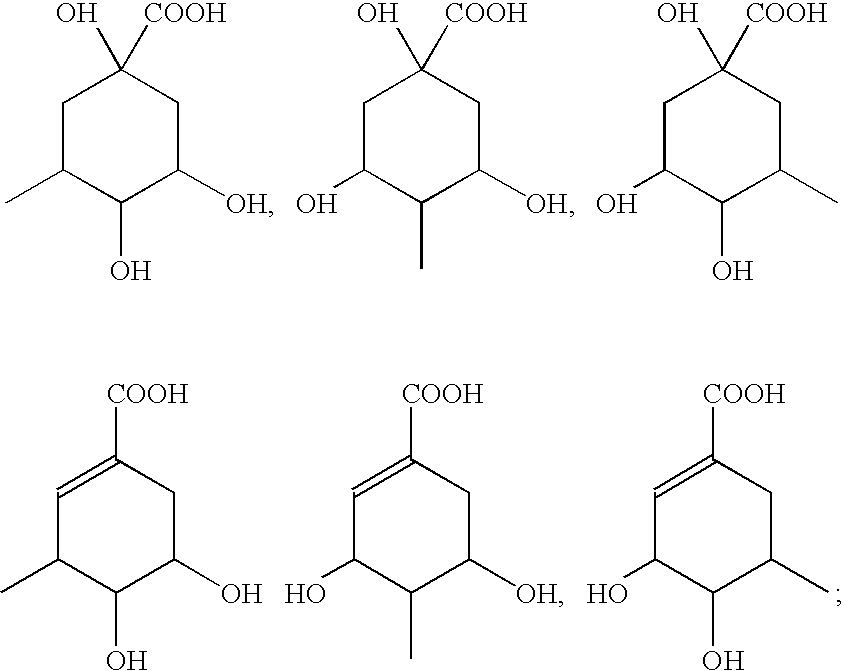

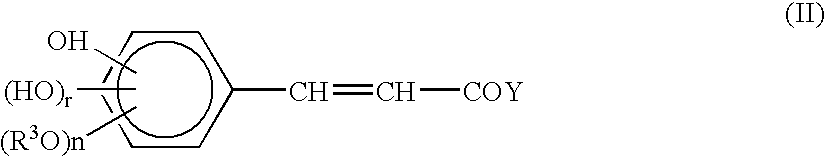

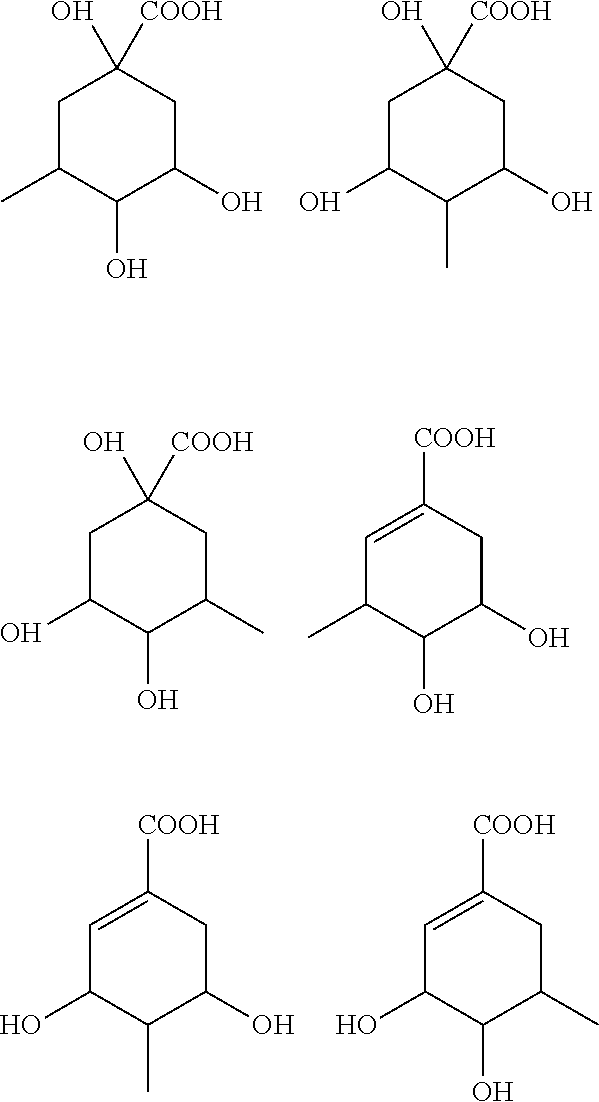

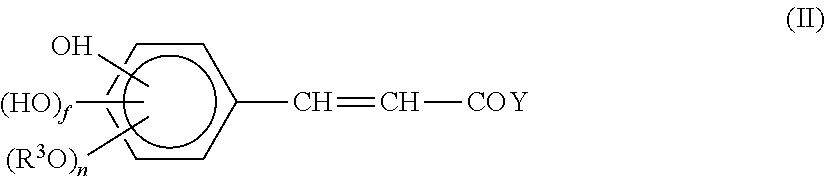

Photoprotector and/or photoimmunoprotector compositions of the skin and their uses

InactiveUS20070025933A1Prevent and minimise damaging effectPrevent and minimise reactionCosmetic preparationsBiocideBenzoic acidPhototherapy unit

The composition comprises of a component A selected from a hydroxylated derivative of benzoic acid or of cinamic acid, their esters, amides or salts, a glycoside of a hexose, and their mixtures; and a component B selected from quinic acid, shikimic acid, their alkaline metal or alkaline earth salts, their methyl esters, and mixtures of the same. This composition is suitable for protecting the skin against ultraviolet radiation coming from the sun or artificial sources, such as those used in phototherapy units and in sun tanning rooms. For application in the field of dermatology and nutrition, and, in particular, in the photoprotection of the skin and mucosa, photo-ageing and photocarcinogenesis, including protection of the immune system associated with the skin.

Owner:IND FARM CANTABRIA

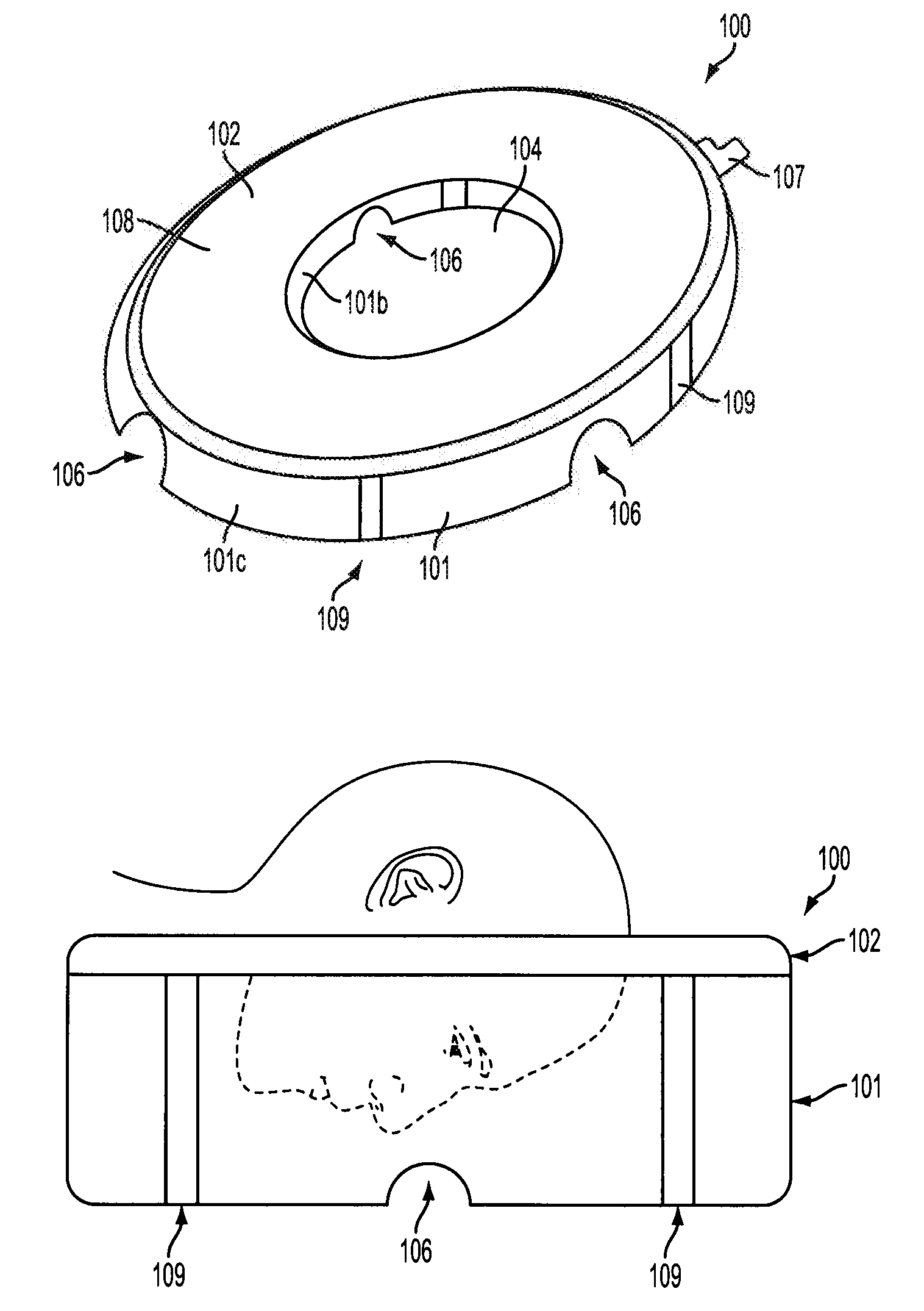

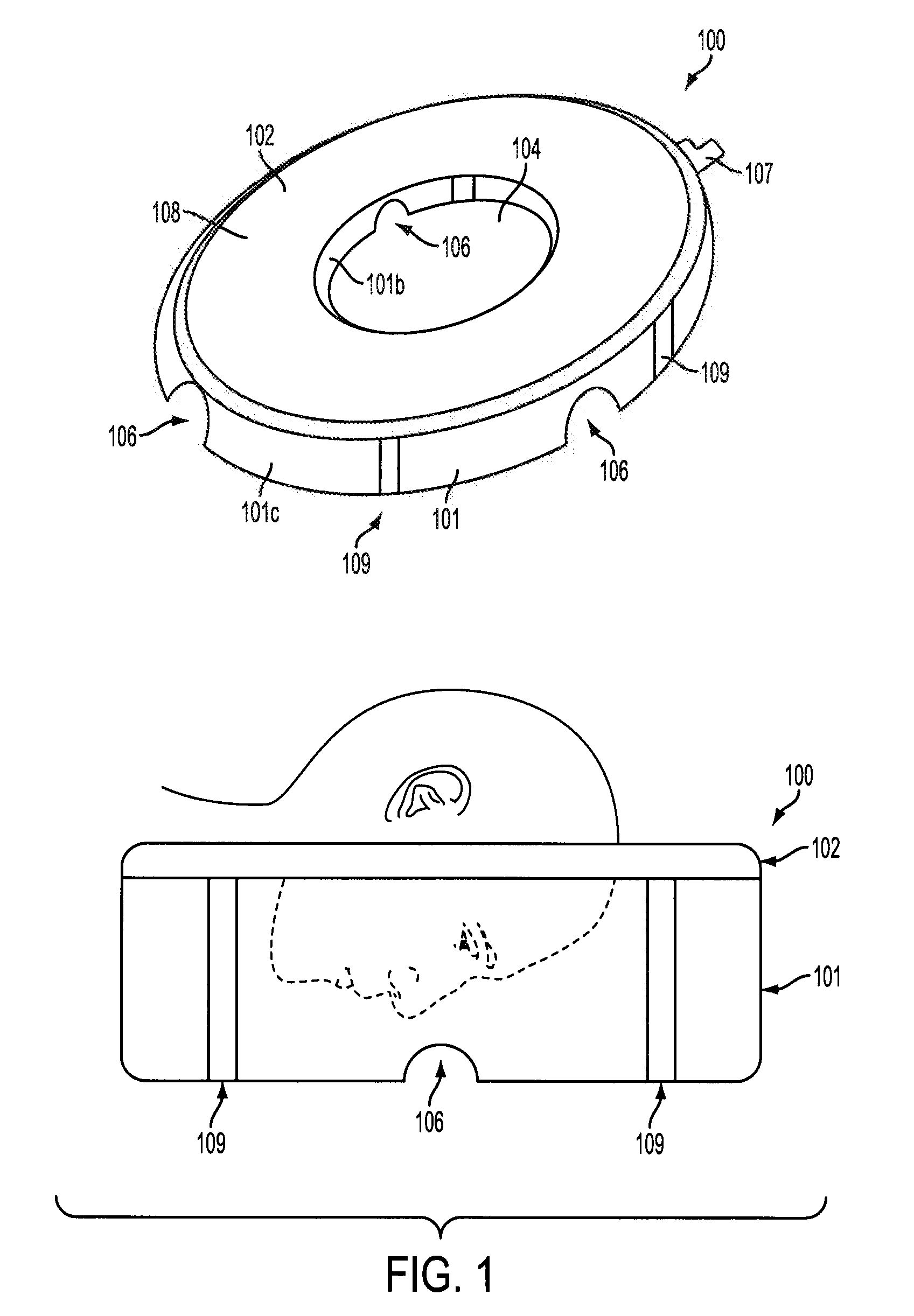

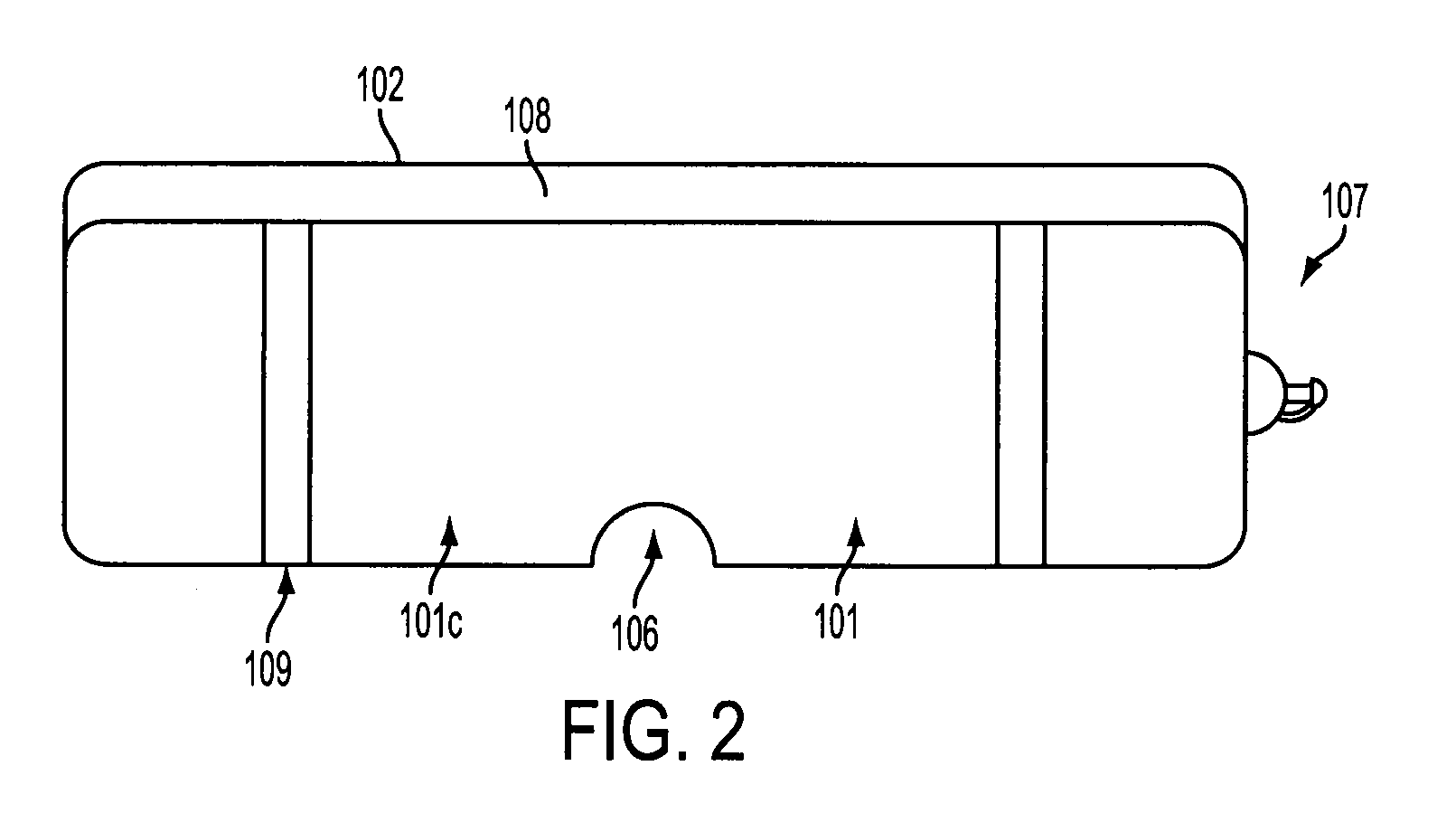

Head and neck supporting device for use while sun tanning, resting prone during massage without a massage table

InactiveUS20100205743A1No rigid structurePreventing uneven facial tanningPillowsBlanketTanning tanningMedicine

A new and improved head and neck support pillow which enables a user to comfortably rest upon his or her stomach. The support pillow is circular with a hole in the center of the pillow which allows the user to insert his or her face. The support pillow also has air holes at the base of the pillow which allows air flow to and from the face for inhalation and exhalation comfort. The support pillow may be completely constructed of PVC plastic with an air valve. The support pillow may be completely inflatable. The support pillow may also be accompanied with a terrycloth or similar fabric cloth which rests on the top of the support pillow for added comfort and is tied to the support pillow around the bottom base of the support pillow. A pocket may be sown in the pillow cover to allow insertion of a fragrance which would give the user an aroma therapy effect and added comfort to the user. A pocket may be sown on the pillow cover that is capable of holding an MP3 player.

Owner:HARCORDELL

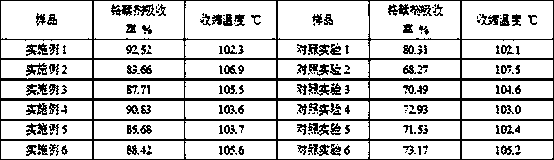

Salt-free pickling-free less-chrome combination tanning method for first layer cattle shoe upper leather

InactiveCN103509888APromote absorptionReduce the content of chromium trioxideTanning treatmentLiquid wasteTanning tanning

The invention relates to a salt-free pickling-free less-chrome combination tanning method for first layer cattle shoe upper leather. In a conventional chrome tanning process, the chromic oxide content in liquid waste with 7 percent of tanned chromium powder is 2000-3000 mg / L, harm is caused to the environment and human health, and the tanning cost is increased due to the shortage of chromium resources. According to the method, an amphoteric polymer-based nano composite less-chrome tanning aid is matched with 3-5 percent of chromium powder to be applied to the tanning process of the first layer cattle shoe upper leather, the shrinkage temperature of wet blue is over 95 DEG C, and the chromic oxide content in the tanned liquid waste is 0.21 g / L and is reduced by 80.5 percent compared with the conventional 7 percent of chromium powder tanning. The tensile strength of crust leather is increased by 38.5 percent compared with that of the conventional 7 percent of chromium powder tanning, and the tearing strength is increased by 50.1 percent. The chromic oxide content in the wastewater can be effectively reduced, the amount of chrome tanning agents is reduced, the use of salts and acids in the tanning process is avoided, and the pollution of chrome tanning liquid waste is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

Water soluble sun tanning solution

A topical solution that looks and performs like an oil, but with the totally non-oil-like characteristic of being completely water soluble. The present invention utilizes materials that have the oil-like look and feel, i.e. polyoxyethylene ethers, but define an end product which is water soluble. Sun screen active ingredients can also be incorporated into this formulation to yield desired SPF values

Owner:BIOCYCLE LAB

Environment-friendly raw skin preservative and preparation method thereof

ActiveCN102399915AImprove anti-corrosion performanceReduce pollutionPre-tanning chemical treatmentLeather impregnationPolymer scienceTanning tanning

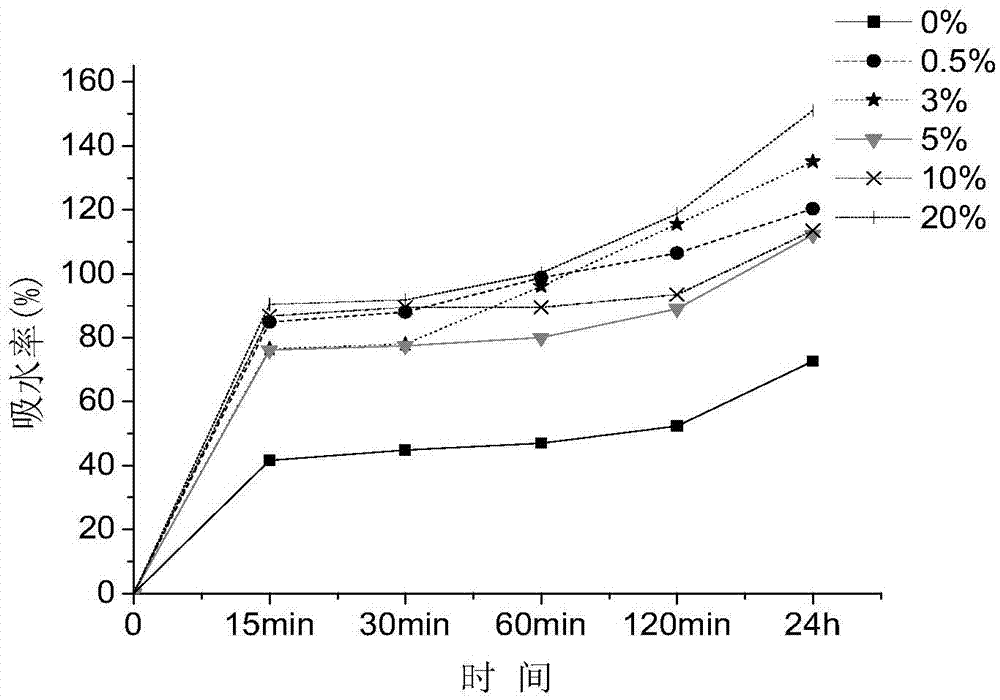

The invention discloses an environment-friendly raw skin preservative and a preparation method thereof. The preservative comprises the following component raw materials in percentage by weight: 42-61% of sodium chloride, 16-27% of polyvinyl alcohol, 16-27% of polyethylene glycol, 0.5-5% of polypropylene glycol, 0.5-5% of polytetrahydrofuran ether glycol and 0.5-2% of polyacrylamide, and the sum of weight percentages is 100%, wherein the molecular weight of polyvinyl alcohol is 25000-35000, the molecular weight of polyethylene glycol is 1000-10000, the molecular weight of polypropylene glycol is 400-2000, and the molecular weight of polytetrahydrofuran ether glycol is 600-2000. The preservative provided by the invention has small usage amount, is safe and nontoxic and can be biologically degraded, the total dissolved solids (TDS) and chloride pollution in tanning waste water can be greatly lowered, and no negative effect is produced on following tanning process.

Owner:SICHUAN UNIV

Preparation method of cationic aldehyde-containing polymer/montmorillonite nano-composite tanning agent

InactiveCN101545016AImprove performanceIncrease profitTanning treatmentTanning tanningMontmorillonite

The invention relates to a preparation method of cationic aldehyde-containing polymer / montmorillonite nano-composite tanning agent. The nano-tanning agents are still in a development stage at present, reports are relatively few. The invention adopts intercalation cyclization polymerization method to prepare strengthening and toughening-type cationic aldehyde-containing polymer / montmorillonite nano-composite tanning agent for leather and takes water-soluble cationic monomer diallyl dimethyl ammonium chloride, acrylamide, glyoxal and montmorillonite as raw materials, the diallyl dimethyl ammonium chloride and the acrylamide are cyclized and polymerized in a montmorillonite layer to prepare poly-diallyl dimethyl ammonium chloride- acrylamide / montmorillonite nano materials which are reacted with the glyoxal to prepare the cationic aldehyde-containing polymer / montmorillonite nano-composite tanning agent for leather. Matching with 2 percent of chrome tanning tanning agent, the tanning tanning agent can make thickening ratio of crust leather reach 71.05 percent, increase the tensile strength to 262.60 percent, and increase the tearing strength by 62.87 percent.

Owner:SHAANXI UNIV OF SCI & TECH

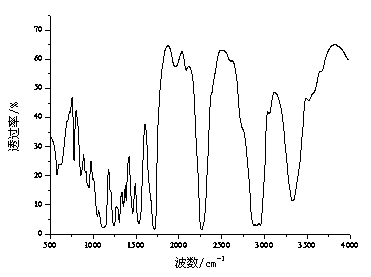

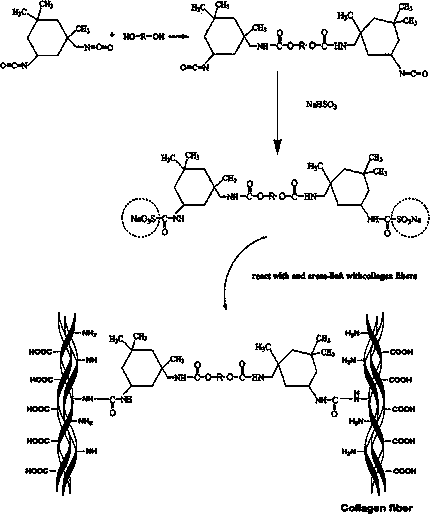

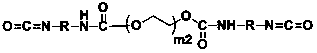

Fur tanning agent based on isocyanate and preparation method of fur tanning agent

The invention discloses a fur tanning agent based on isocyanate and a preparation method of the fur tanning agent. According to the process, diisocyanate molecules are adopted to perform end-capping on two ends of fat-diol or polyether glycols in a mixed solution under the condition of catalysis, and prepolymer with high selectivity and high conversion rate is obtained; then, hydrosulphite is adopted to protect isocyanate groups on two ends of the prepolymer, the water solubility of the compound is increased, and the tanning agent is obtained finally. The molecular weight of the tanning agent can be controlled, thereby being applicable to tanning of furs with different fibrous textures; during the tanning process, the fur tanning agent can effectively permeate to the position among the fur collagen; hydrosulphite decomposes under the condition of raised temperature and raised alkali, the tanning agent molecule expose the isocyanate group to cause the isocyanate group to react with the amino group on the collagen molecule, crosslinking of the fur collagen is realized, and the purpose of tanning is achieved; only neutral salt is released during the entire process, heavy metal ions or free aldehyde groups are not generated, the process is simplified, the fur tanning agent is environment friendly, the price is low, the fur tanning agent is very suitable for fur, especially tanning of rabbit fur with light color.

Owner:SICHUAN UNIV

Method for tanning sheepskin garment leather using non-chromium metal composite tanning agents

InactiveCN101381783AImprove matchGood factory industrial production baseTanning treatmentSludgePhosphor

The invention relates to a method for tanning ultrathin goat clothing leather by a chrome-free metal composite tanning agent. The method comprises the steps of acid enzyme bating and tanning; and in the tanning process, an LTA-100 type metal (chrome-free) composite tanning agent, a chrome-free tanning additive D5, a tanning promoting agent GM-15 and the like are adopted. The method is characterized in that leather in industrialized production has the thickness of between 0.4 and 0.6 millimeter and good strength; and the shrinkage temperature can reach over 90 DEG C; the leather has no pollution of chrome and phosphor, releases no formaldehyde, has rich coloration and is more suitable to be manufactured into white leather than chrome tanning leather; and sludge for manufacturing leather can be directly incinerated and has no potential danger of hexavalent chrome. The method can substitute the tanning of the prior chrome powder to the leather and remove the pollution of production process and chrome salt in waste of a leather product to human and environment simultaneously, thereby creating a new approach for producing the chrome-free tanning leather and the clothing leather in a tannery.

Owner:WENZHOU UNIVERSITY

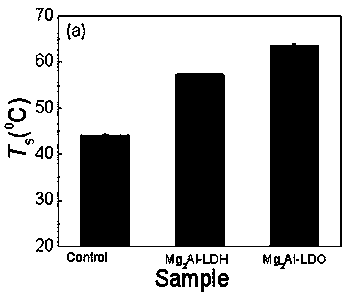

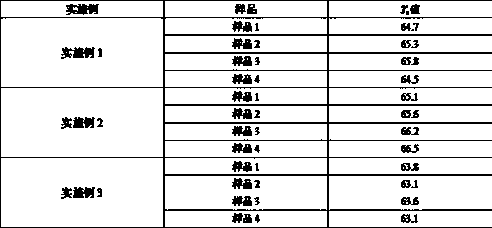

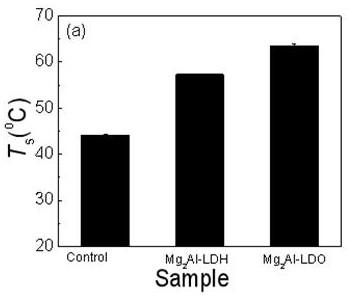

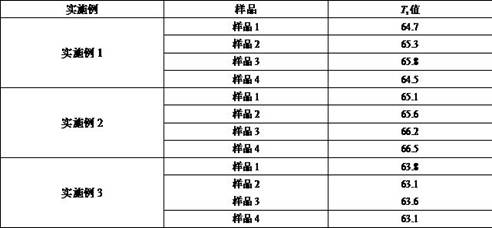

Nano tanning agent based on structural memory effect, preparation method and applications thereof

ActiveCN111004877AUnique structure memory effectLarge specific surface areaTanning treatmentTanning tanningFreeze-drying

The invention discloses a nano tanning agent based on a structure memory effect, a preparation method and applications thereof. A purpose of the invention is to increase the specific surface area of atanning agent and enhance the adsorption performance. According to the technical scheme, the preparation method of the nano tanning agent based on the structure memory effect comprises: respectivelyweighing magnesium nitrate and aluminum nitrate, and dissolving in water to prepare a metal salt solution A; dissolving sodium carbonate in water to prepare a sodium carbonate solution B; and adding the solution A into the solution B in a dropwise manner, regulating the pH value to 10-12 by using a sodium hydroxide solution, carrying out nucleating crystallizing for 10 hours at a temperature of 75DEG C, centrifuging, freeze-drying, and calcining the obtained product for 2-4 hours at a temperature of 350-450 DEG C to obtain the nano tanning agent. According to the invention, the prepared nanotanning agent has a unique structural memory effect; and in a tanning process, the nano tanning agent is assembled with leather collagen fibers to form an organic / inorganic nano hybrid material by adjusting the external environment, so that the shrinkage temperature of crust leather is increased.

Owner:SHAANXI UNIV OF SCI & TECH

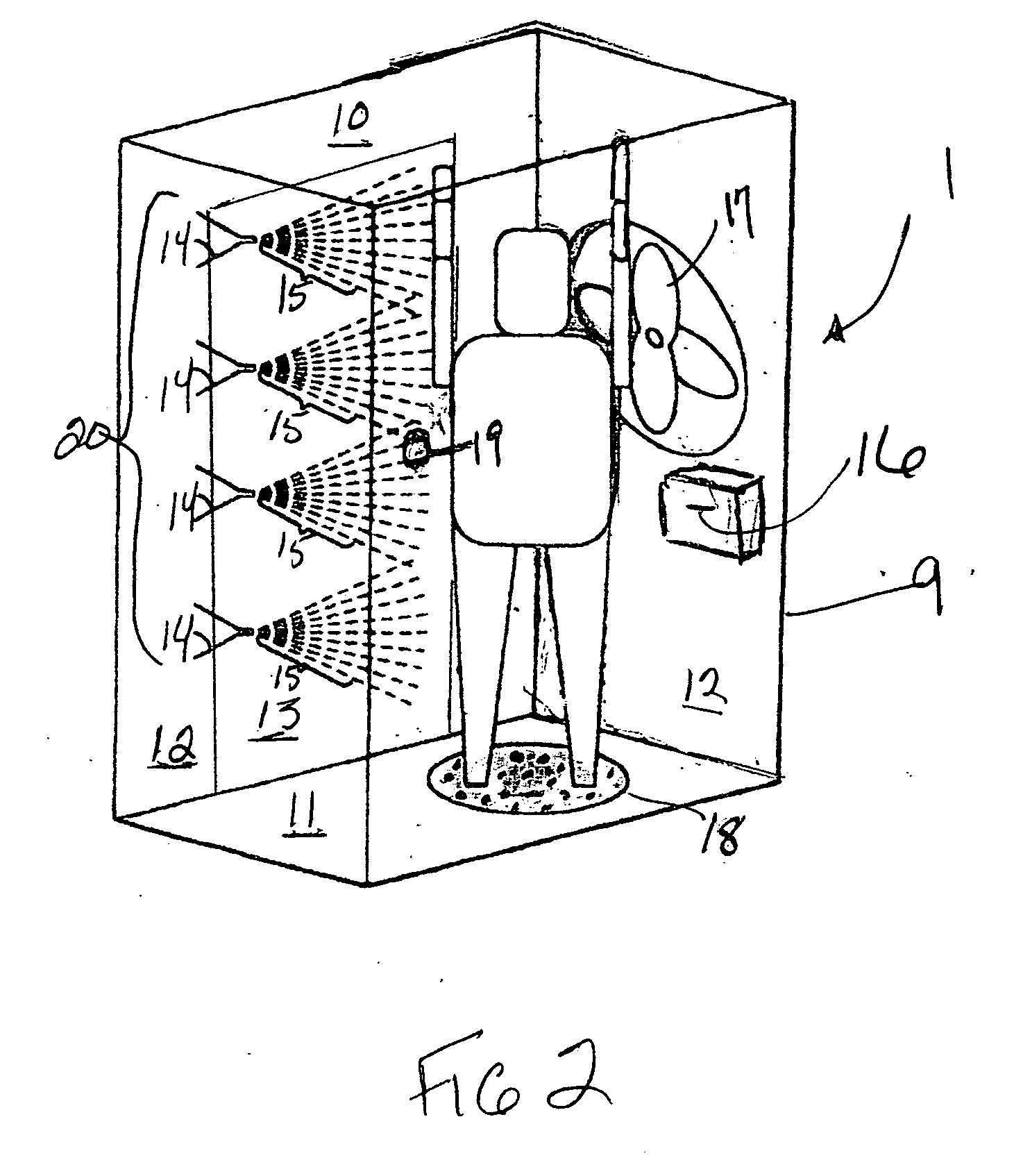

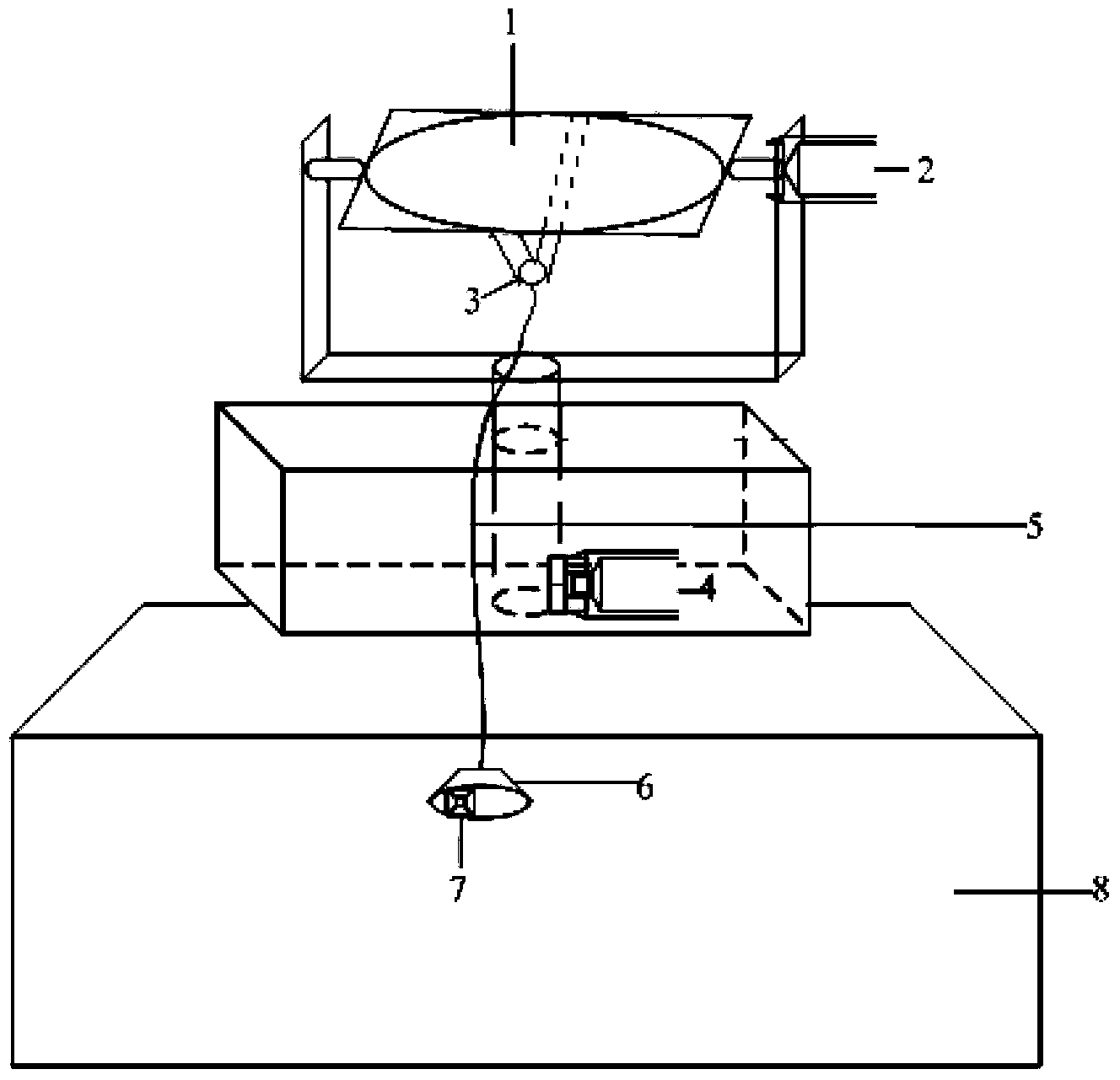

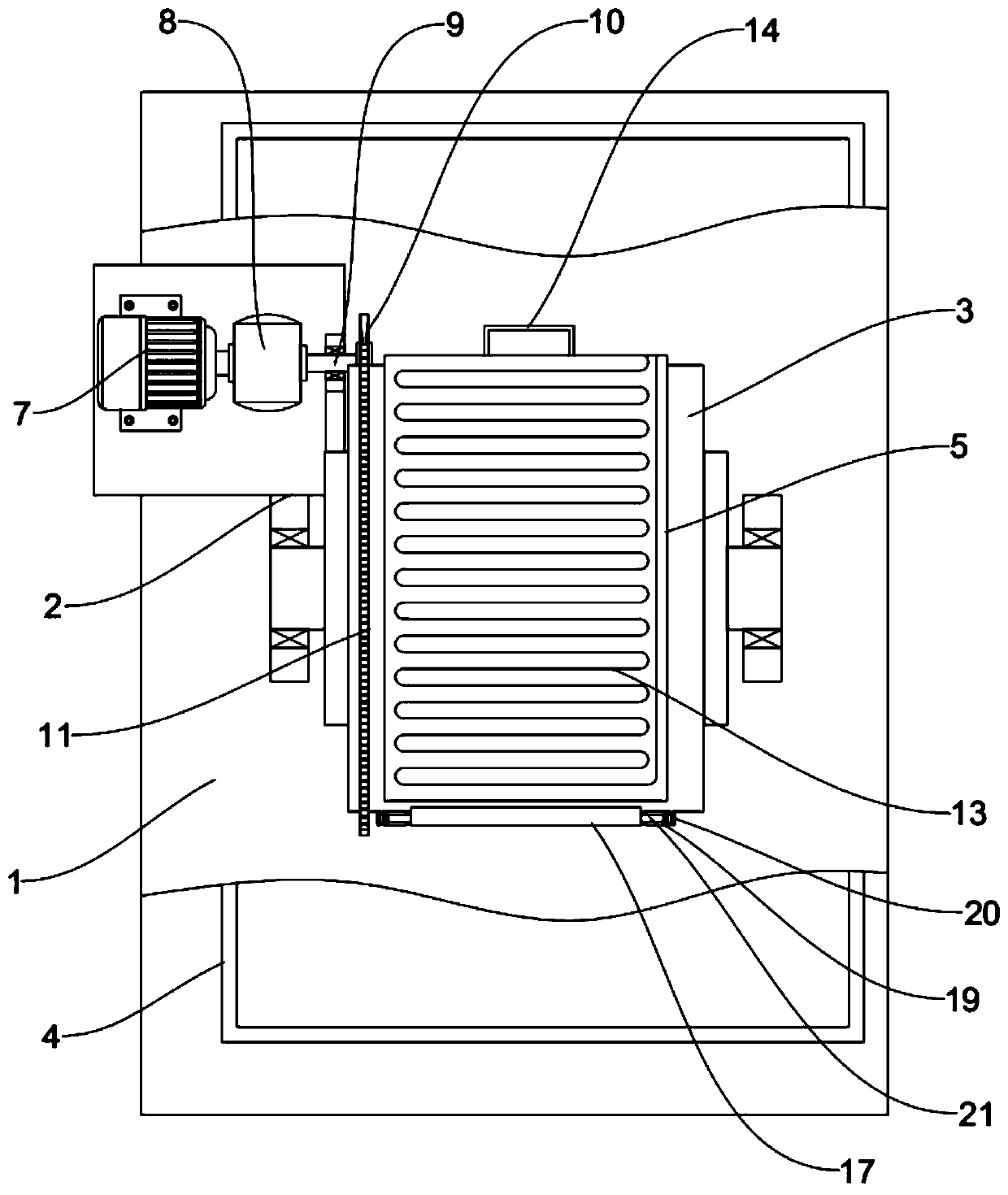

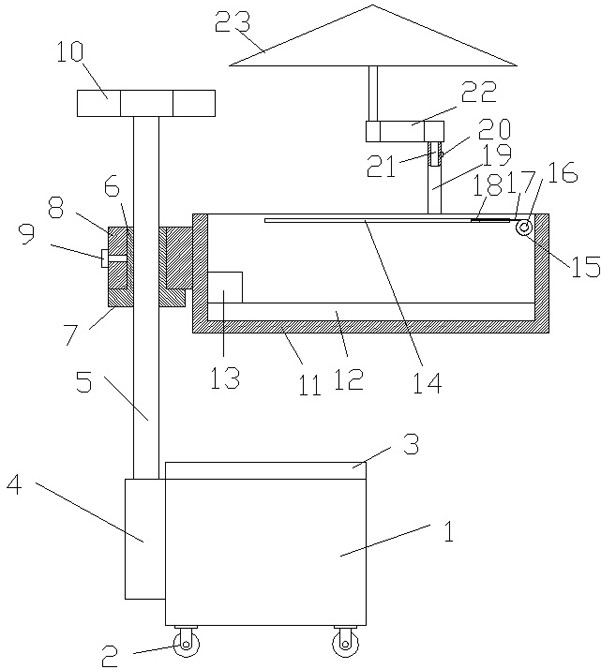

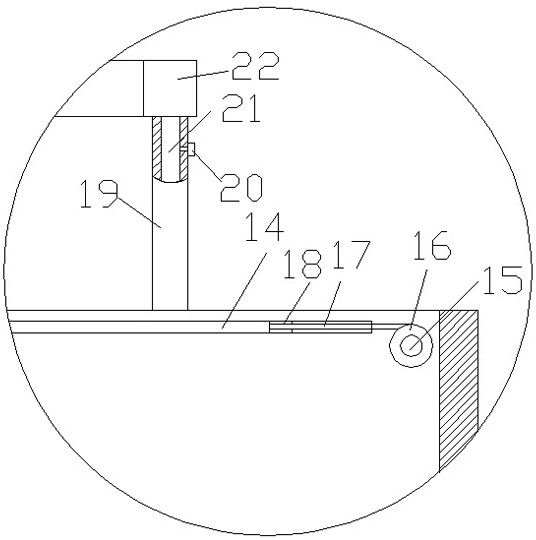

Indoor sun tanning device based on optical fiber light guiding and working method

InactiveCN103405854AImprove actual functionsGuaranteed to receiveControl using feedbackLight therapyTanning tanningEffect light

The invention relates to an indoor sun tanning device based on optical fiber light guiding. The indoor sun tanning device comprises a lighting unit, an illumination tracking and control unit, a light filter, an optical fiber transmitting unit and a light scattering unit. The illumination tracking and control unit comprises a central control module and a cloud deck driven by a longitudinal motor and a transverse motor in a three-dimension mode; the lighting unit is installed on the cloud deck to collect daylight, and is connected with the optical fiber transmitting unit through the light filter; collected daylight is focused by the lighting unit, is filtered by the light filter and then enters a room of a building through the optical fiber transmitting unit; the light scattering unit is arranged at the light outlet end of the optical fiber transmitting unit. The indoor sun tanning device achieves the purpose of tracking and collecting daylight in the daytime in an omni-directional and no-dead-angle mode.

Owner:SHANDONG UNIV

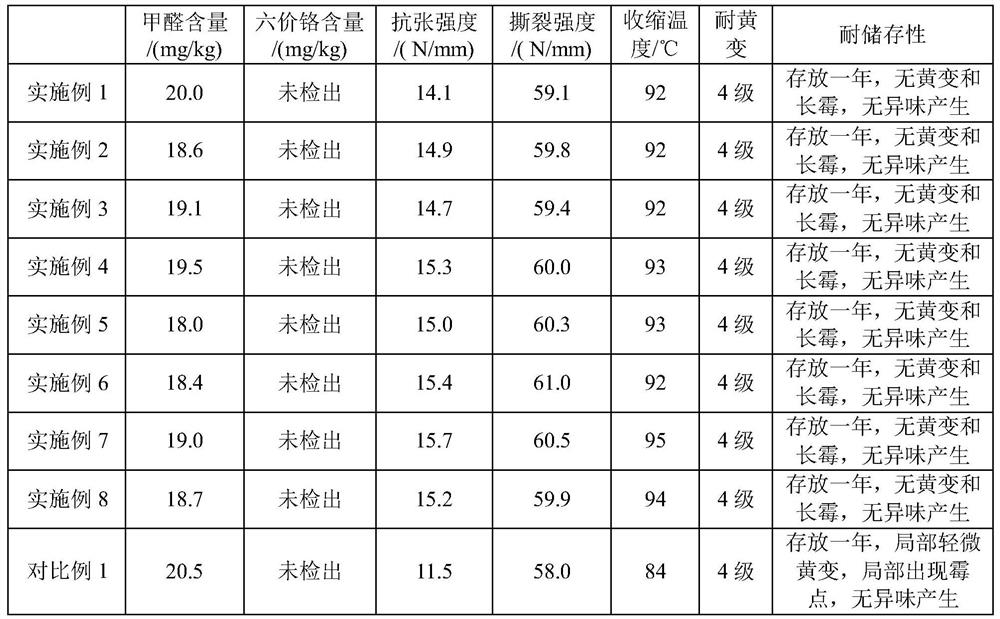

Chrome-free Tanning Technology of Sheep Leather and Sheep Wetwhite and Sheep Leather

ActiveCN110628968BBiodegradableImprove securityTanning treatmentPre-tanning chemical treatmentBiotechnologySheep skin

The invention relates to a processing technology for chrome-free tanning of sheep leather, which comprises the following processing steps in sequence: soaking in water, plucking with alkali, liming, deliming and softening, degreasing, pickling tanning, retanning and dyeing, finishing and finishing; In the pickling tanning step, the chrome-free tanning agent TWLZ is used to tan the degreased leather without chrome to obtain wet white leather, which is retanned and dyed, finished and finished to obtain sheep leather; the chrome-free tanning process has been successfully Applied to sheep leather to produce wet white leather and sheep leather. The tanning process does not produce chromium-containing wastewater and chrome leather shavings, which is green and environmentally friendly; the shrinkage temperature of the prepared wet white leather can reach up to 95°C, and the performance is good; the whiteness is good, and a No discoloration within one year, good storage resistance, yellowing resistance level 4; finished sheep leather has good air permeability, and the shrinkage temperature can reach above 90°C.

Owner:辛集市凌爵皮革有限责任公司

Method for tanning cattle hide upper leather using non-chromium metal composite tanning agent

The invention relates to a method of tanning cattle shoe upper leather with non-chrome metal compound tanning agent, comprising steps of pre-treatment, tanning and after-treatment. LTA-100 metal (chrome-free) compound tanning agent, chrome-free tanning partner D5, tanning assisting agent GM-15 and the like are adopted during the process of tanning. The invention is characterized in that: the shrinkage temperature of leather in the industrialized production can be stabilized above 85 DEG C, even above 90 DEG C; chrome pollution and phosphorus pollution are not produced, and formaldehyde is not released; the dyeing color is so rich that the color is better for white rather than that of the chrome tanning leather; the tannery sludge can be directly burned without causing potential danger of hexavalent chrome. The invention can be sued for substituting the traditional technique of leather tanning by chrome powder, meanwhile eliminating pollution to humankind and environment by chromium salts during the process and in the wastes of leather products. The productobtained by the method has good strength, thus blazing a trail in producing chrome-free tanning cattle shoe upper leather for tanneries.

Owner:WENZHOU UNIVERSITY

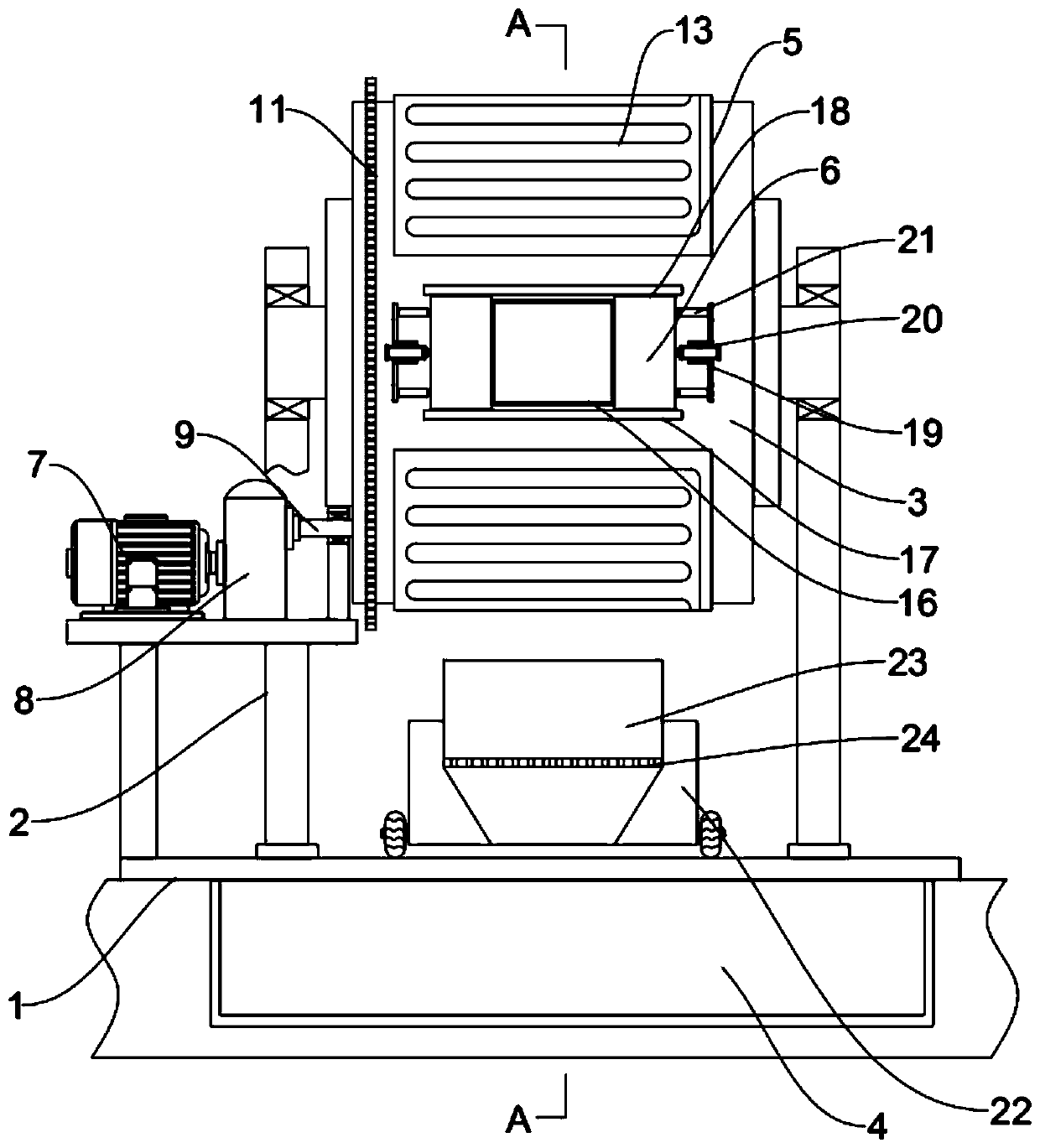

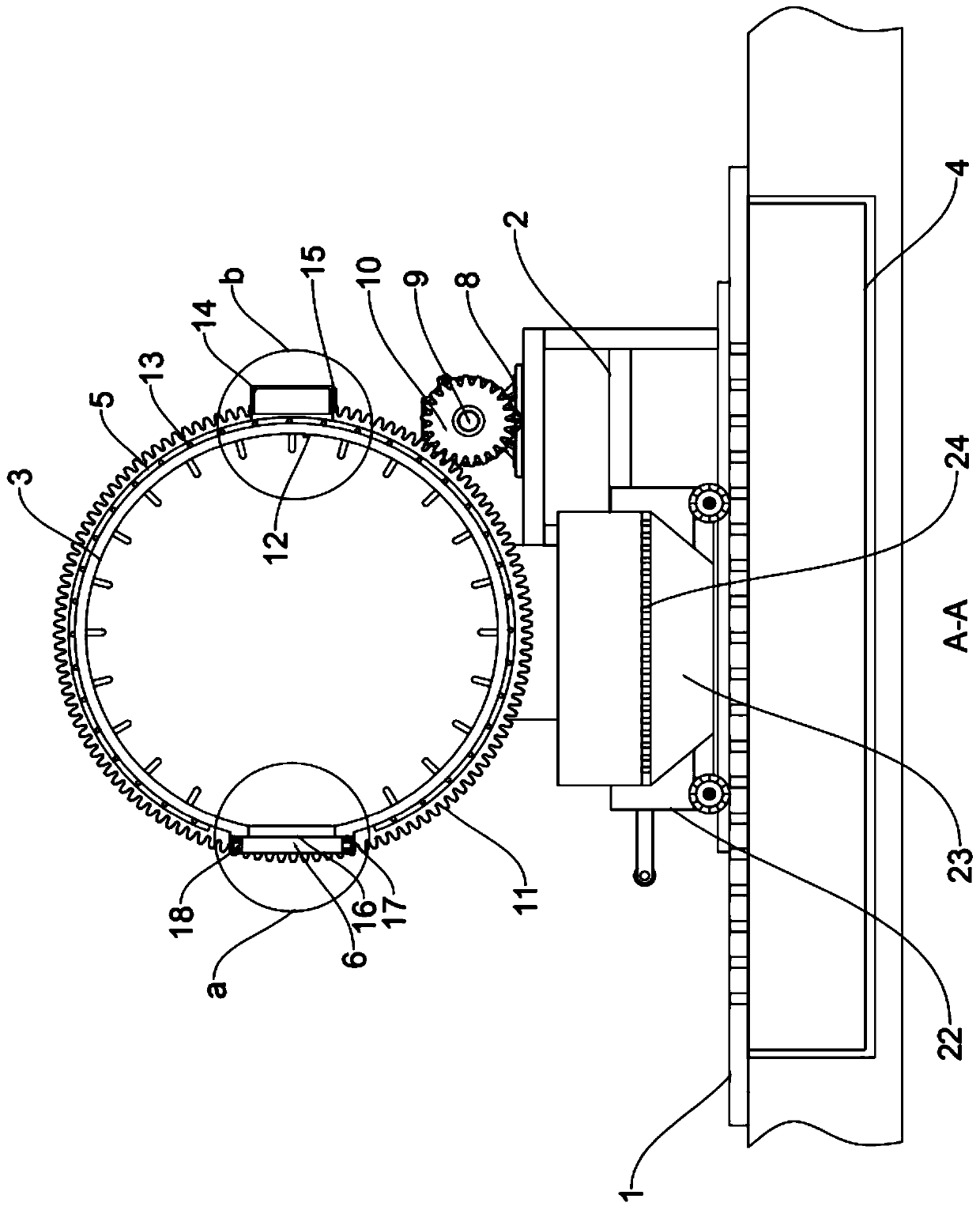

Environment-friendly tanning method and device of leather

InactiveCN111304376AEasy to handleStabilizationLeather manufacturingLeather clicking/perforating/clickingSodium bicarbonateTanning tanning

The invention discloses an environment-friendly tanning method and device of leather. The method comprises the following steps of S1, raw material pretreatment; S2, tanning treatment; S3, rinsing andneutralizing; and fourthly, finishing treatment. The environment-friendly tanning device of the leather comprises a base, a fixed frame and a rotating cylinder. The fixed frame is mounted on the base,the rotating cylinder is mounted on the fixed frame and is rotatably connected with the two ends of the fixed frame, a waste water recycling bin is mounted below the base and communicates with the base, an existing leather tanning method is improved, temperature and PH value in the raw leather tanning process can be adjusted, the tanning speed is improved, in the whole tanning process, a plant tanning agent, ammonium sulfate and sodium chloride serve as main components of tanning liquid, neutralizing is carried out through sodium bicarbonate, waste water treatment is easy, and the whole process is environment-friendly.

Owner:ZHONGNIU GRP

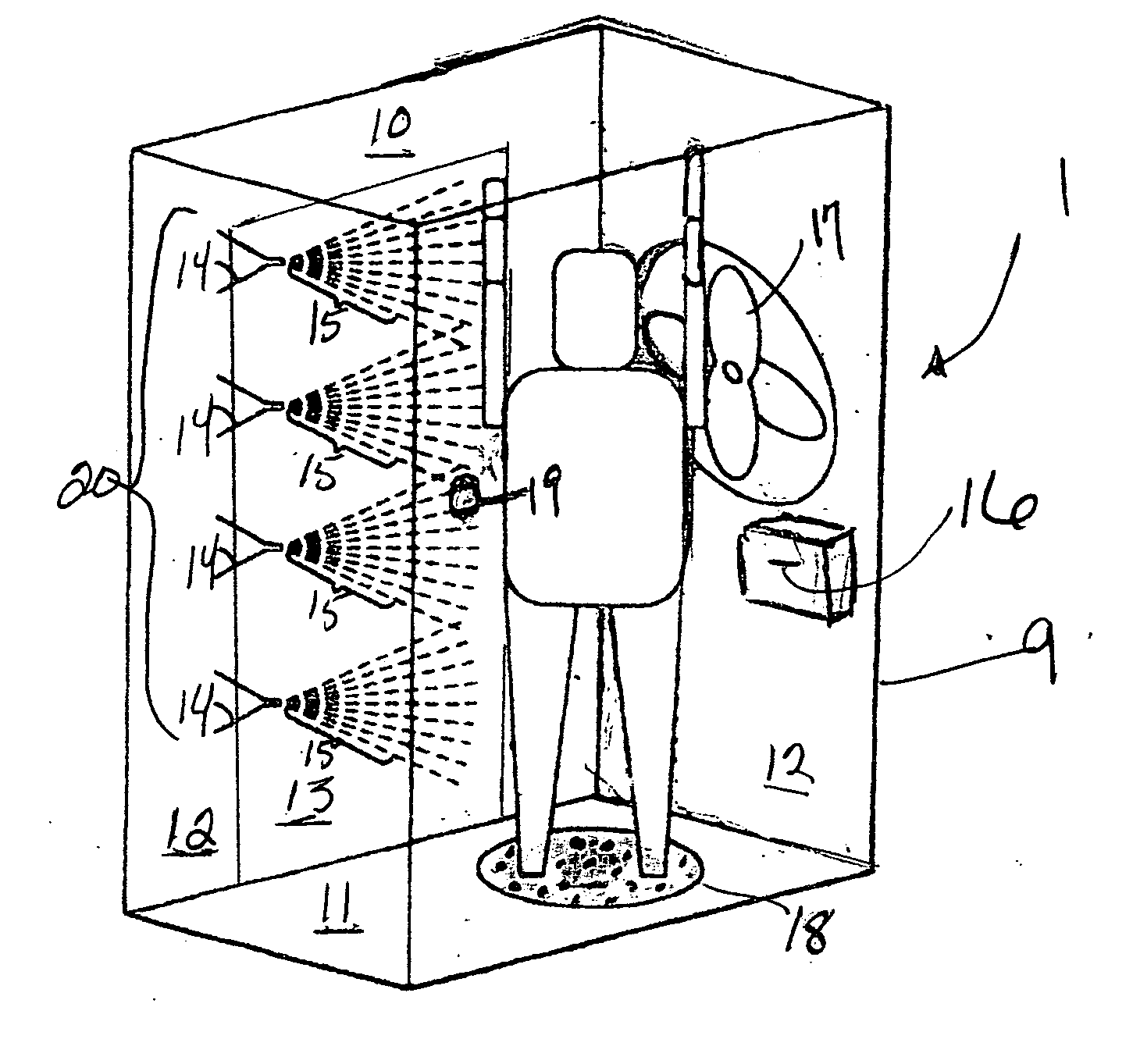

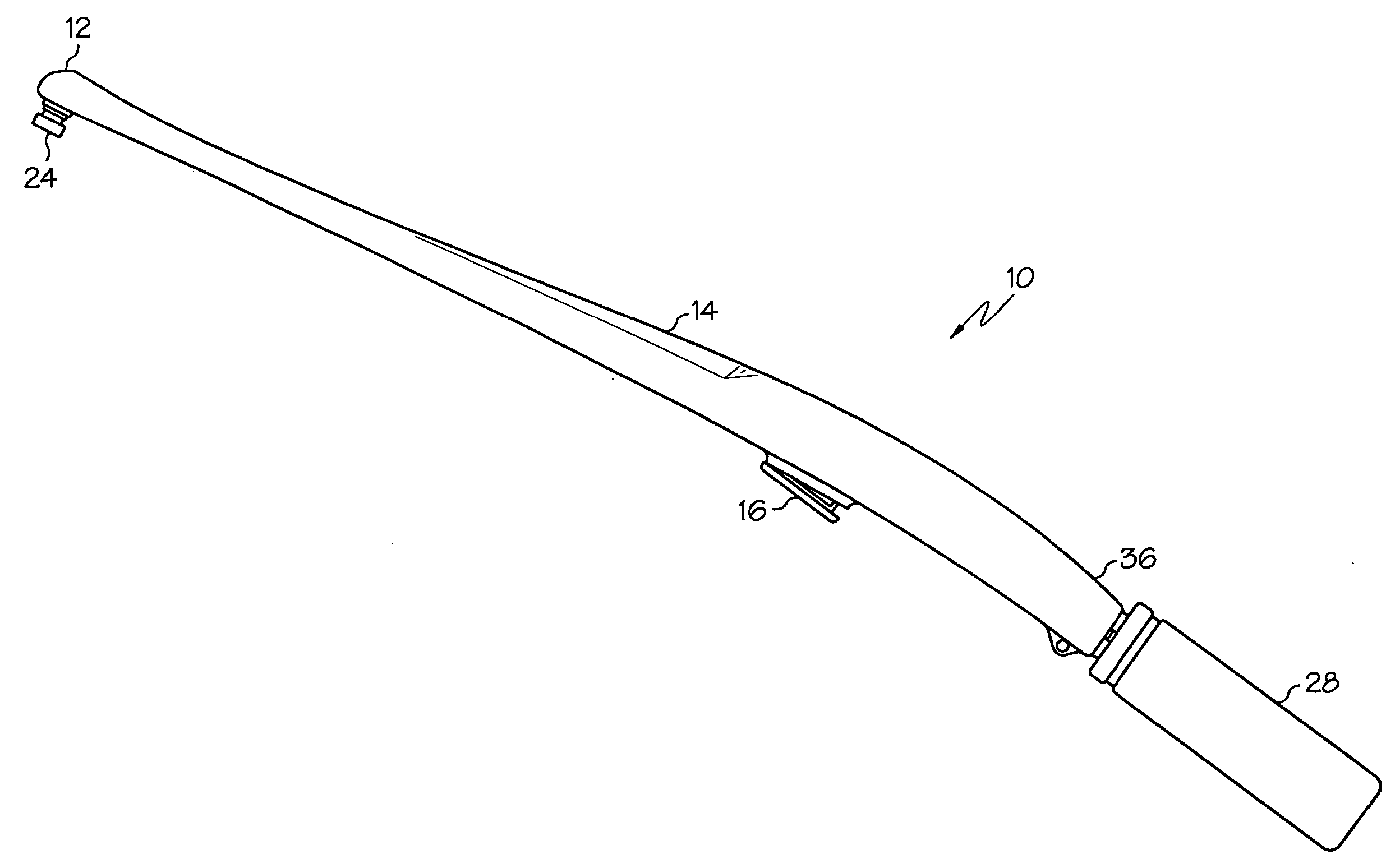

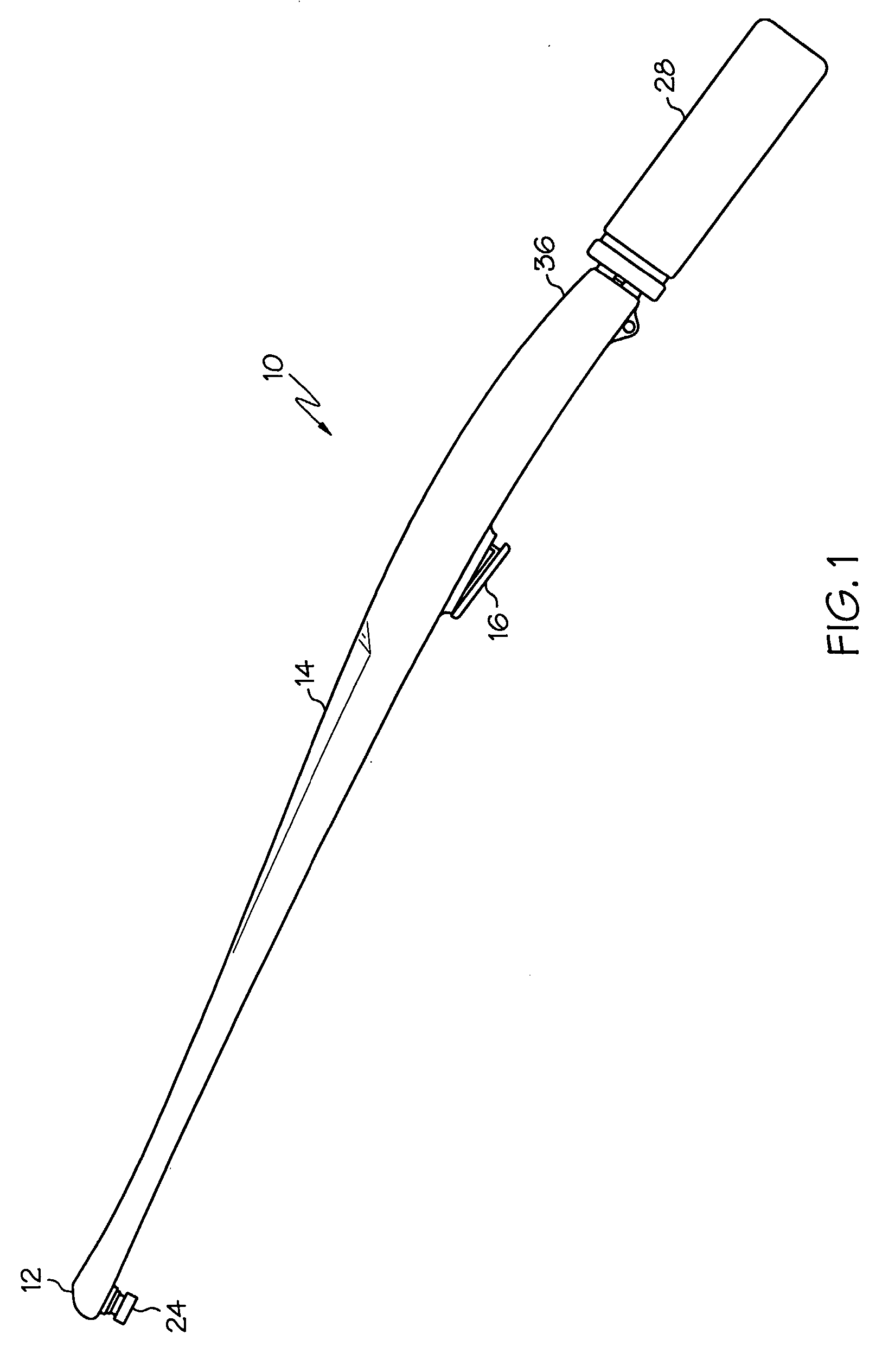

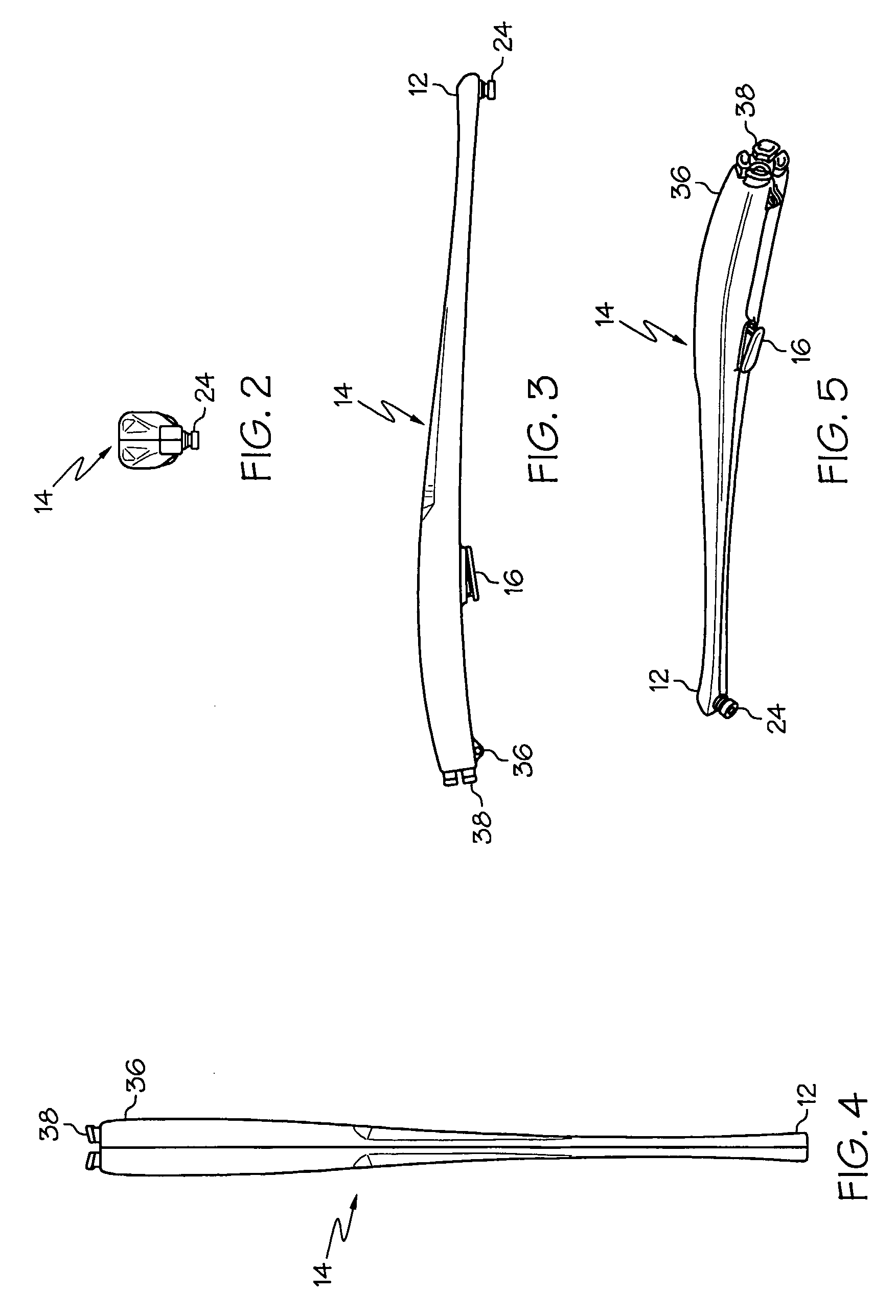

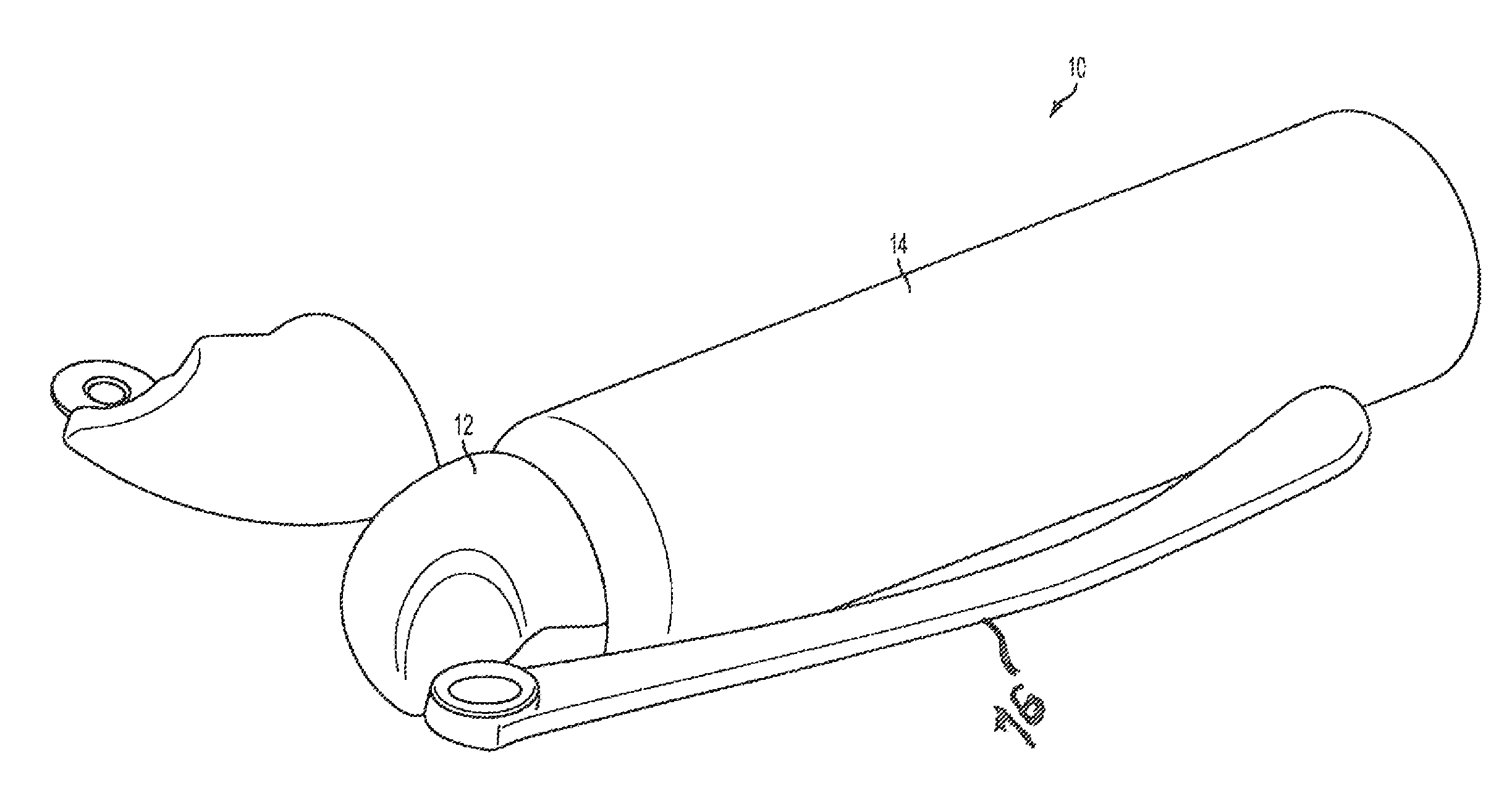

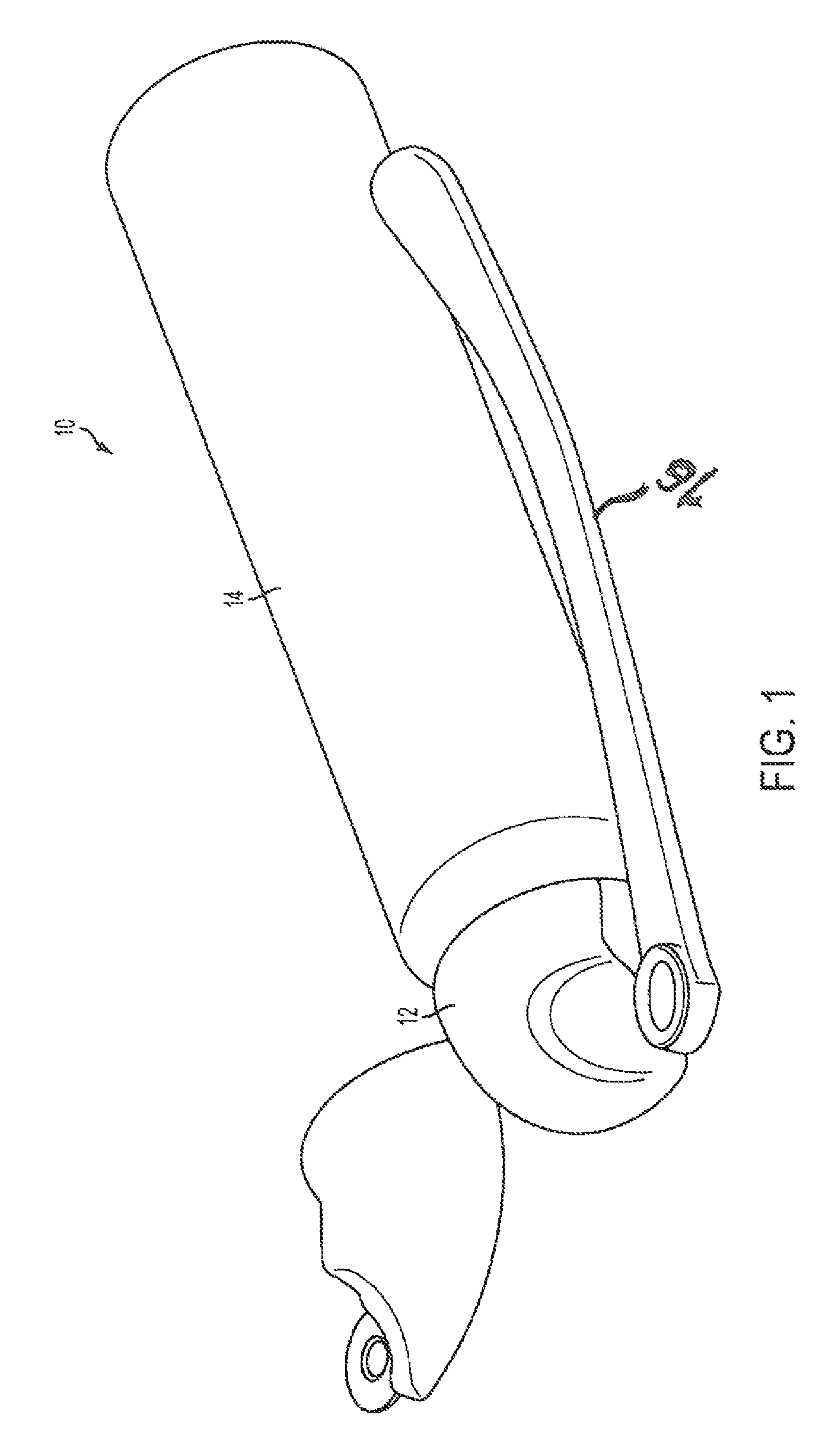

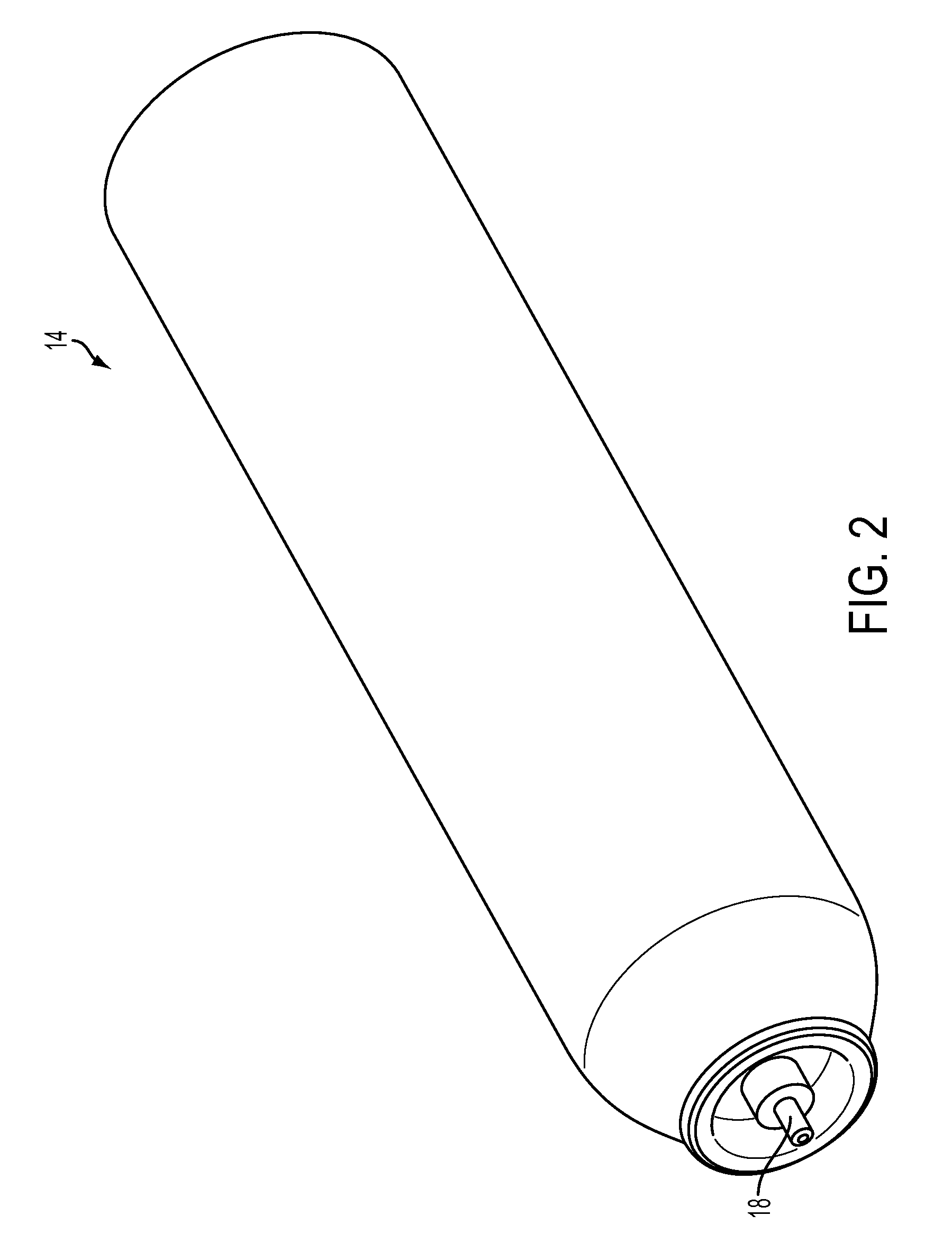

Spray Tanning Delivery Device

An apparatus for delivering liquid utilizing a wand with a nozzle, a toggle switch, and a supply canister for delivering self-tanning and sun-tanning solutions to a human body is disclosed. Projections on the wand facilitate a direct connection to a supply canister containing the chosen liquid to be delivered without the necessity of an exposed external tube suspended between the wand and the supply canister. The wand may be detached and reattached to the supply canister for storage or use.

Owner:CALIFORNIA BLUE

A kind of nano tanning agent based on structural memory effect and its preparation method and application

ActiveCN111004877BUnique structure memory effectLarge specific surface areaTanning treatmentTanning tanningFreeze-drying

The invention discloses a nano tanning agent based on structural memory effect and its preparation method and application, which improves the specific surface area of the tanning agent and enhances the adsorption performance. The technical solution of the present invention is: a preparation method of a nano-tanning agent based on the structural memory effect, respectively weighing magnesium nitrate and aluminum nitrate and dissolving them in water to prepare metal salt solution A, and dissolving sodium carbonate in water to prepare sodium carbonate solution B; Then add solution A dropwise into solution B, and at the same time adjust the pH value to 10~12 with sodium hydroxide solution, nucleate and crystallize at 75°C for 10 hours, centrifuge, freeze-dry, and then put the obtained product at 350°C~450°C Calcined at ℃ for 2~4h to get nano tanning agent. The nano tanning agent prepared by the invention has a unique structure memory effect. During the tanning process, the external environment is adjusted to form an organic / inorganic nano hybrid material by adjusting the external environment to increase the shrinkage temperature of crust leather.

Owner:SHAANXI UNIV OF SCI & TECH

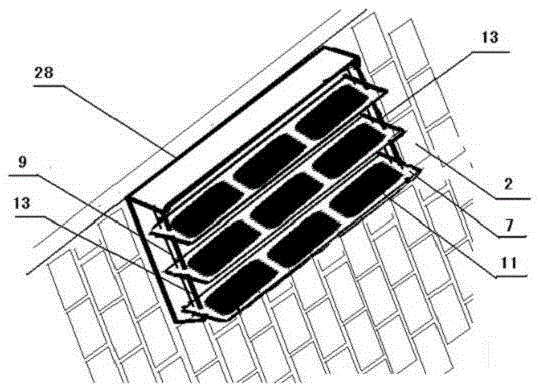

Method for collecting and utilizing building window/veranda solar energy

InactiveCN105262415ASolve the use problemLow running costPhotovoltaic supportsPhotovoltaic energy generationTanning tanningResource utilization

The invention relates to a method for collecting and utilizing the building window / veranda solar energy. According to the technical scheme of the invention, cuboid-like frames are fixed outside the outer wall of a building and one frame is set for each family as a unit. Each frame is covered onto the lighting surface to be utilized by one family. A track parallel to a facade wall is fixedly arranged on the frames. On the track parallel to the facade wall, movable bunched blades are fixedly connected with the track via movable intermediate members. The blades are integrated with solar power members. The bunched blades are controlled to expand and form an array, so that a lighting body approximately parallel to the fa ade wall is formed. The lighting body is used for photovoltaic power generation. Based on the above method, the solar radiation on the sunny slope of the window / veranda of a building can be utilized, so that the resource that cannot be utilized in other ways can be utilized. Therefore, the temporal air-gap resource utilization problem can be ingeniously solved. Meanwhile, the family operation cost of each family is saved. Moreover, the normal life and the sun tanning of the owner of the building are not disturbed at all.

Owner:张国柱

Environment-friendly raw skin preservative and preparation method thereof

ActiveCN102399915BReduce pollutionLow costPre-tanning chemical treatmentLeather impregnationPolymer scienceTanning tanning

The invention discloses an environment-friendly raw skin preservative and a preparation method thereof. The preservative comprises the following component raw materials in percentage by weight: 42-61% of sodium chloride, 16-27% of polyvinyl alcohol, 16-27% of polyethylene glycol, 0.5-5% of polypropylene glycol, 0.5-5% of polytetrahydrofuran ether glycol and 0.5-2% of polyacrylamide, and the sum of weight percentages is 100%, wherein the molecular weight of polyvinyl alcohol is 25000-35000, the molecular weight of polyethylene glycol is 1000-10000, the molecular weight of polypropylene glycol is 400-2000, and the molecular weight of polytetrahydrofuran ether glycol is 600-2000. The preservative provided by the invention has small usage amount, is safe and nontoxic and can be biologically degraded, the total dissolved solids (TDS) and chloride pollution in tanning waste water can be greatly lowered, and no negative effect is produced on following tanning process.

Owner:SICHUAN UNIV

Spray device

Owner:BOYNE CANDICE ALICE

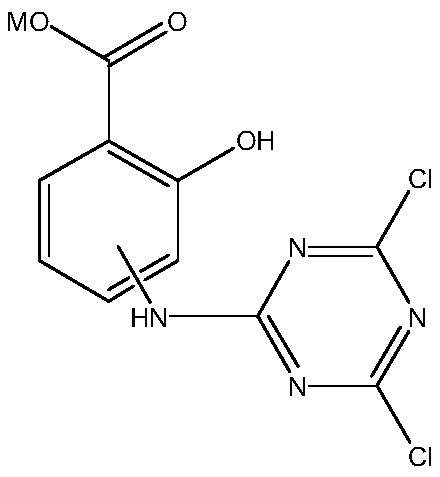

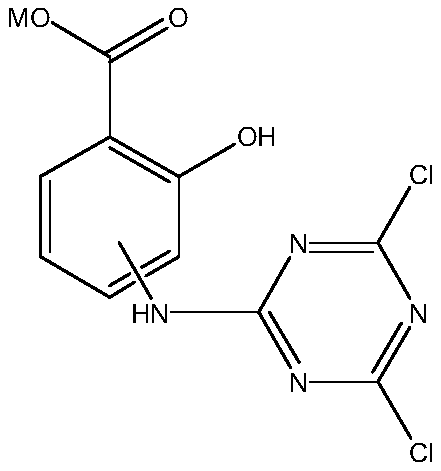

Chromium-free leather tanning method

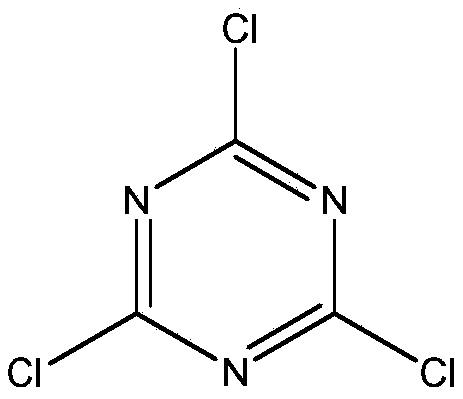

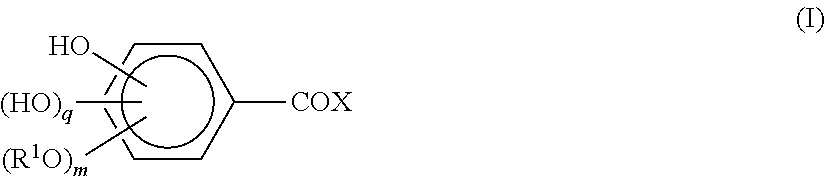

ActiveCN111118234AImprove tanning effectIncrease shrinkage temperatureTanning treatmentPre-tanning chemical treatmentTanning tanningAluminum sulphate

The invention discloses a chrome-free leather tanning method. The chrome-free leather tanning method comprises three steps of deacidification, organic chlorine tanning agent tanning and aluminum tanning. The method comprises the following steps: deacidifying pickled skin; adding an organic chlorine tanning agent to carry out first tanning treatment on leather, wherein the structural formula of theorganic chlorine tanning agent is that the substituent group 4,6-dichloro-1,3,5-triazine-2-amine group is located at the ortho position, meta position or para position of salicylate hydroxyl, and M is H, Na or K; after tanning with the organic chlorine tanning agent, adding an aluminum tanning agent to further tanning leather, wherein aluminum sulfate is selected on the aluminum tanning agent. Inthe tanning process of the invention, no chromium-containing substance is used, chromium pollution is not generated, and the whole tanning process is more green and environment-friendly; at the sametime, the chrome-free leather tanning method has good tanning effect on the leather, and the shrinkage temperature reaches above 95 DEG C or above.

Owner:WENZHOU UNIVERSITY

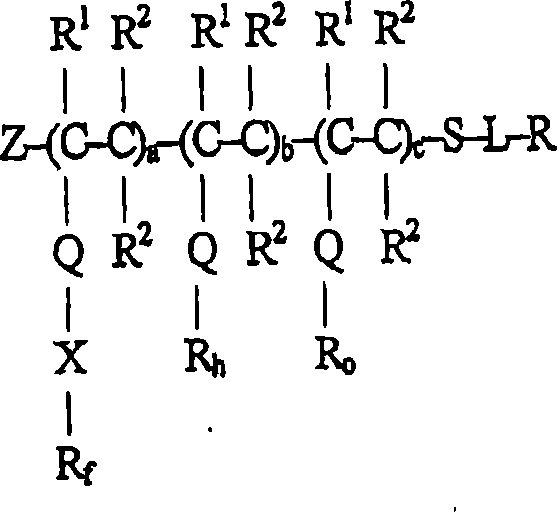

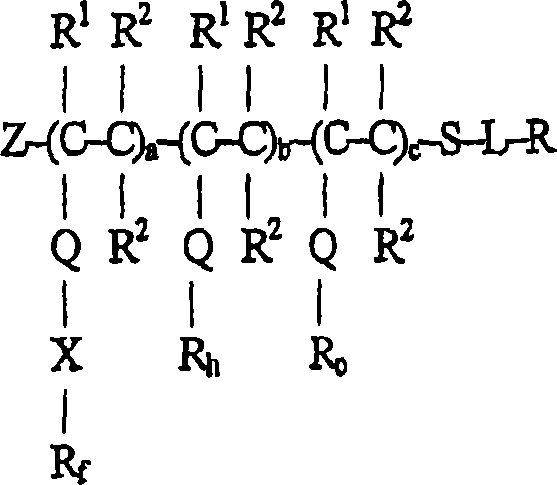

Washable leather with oil- and water-repellency

Washable leather having durable oil repellency, durable soil removal and durable water repellency, and a method of making the same, comprising exposing the leather to a composition comprising at least one fluorinated amino group during a tanning process are disclosed Ethyl formate; at least one fluorinated ester; mixtures thereof; or a mixture of at least one fluorinated ethyl citrate carbamate with at least one fluorinated ethyl carbamate, at least one fluorinated ester, or a fluorinated amino Mixture of ethyl formate and fluorinated esters.

Owner:EI DU PONT DE NEMOURS & CO +1

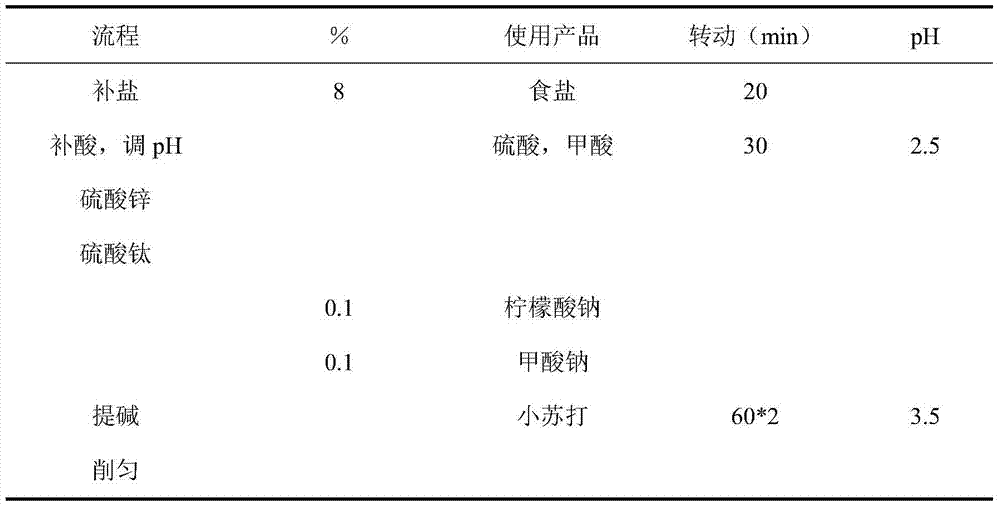

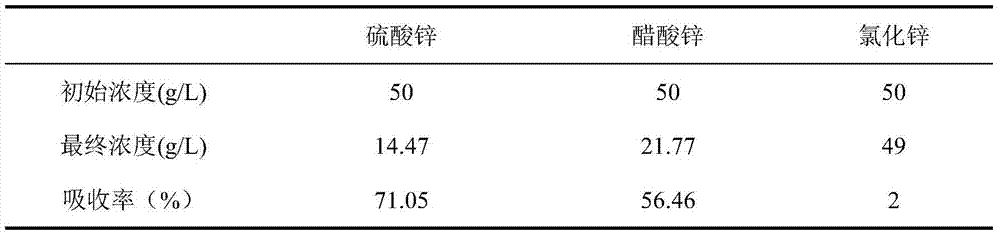

Method for tanning by jointly using compound protease soaked with water, titanium salt and zinc salt

ActiveCN105441602AReduce processing difficultyMeet environmental protection requirementsTanning treatmentPre-tanning chemical treatmentChromium freeAlkaline protease

The invention relates to a method for tanning leather by jointly using alkaline protease, titanium salt and zinc salt. When the alkaline protease serves as a soaking auxiliary agent, NaCl is adjusted in a soaking process. Compared with a simple soaking method, the method can effectively shorten the time by 8-10 hours, and wet-white leather tanned by titanium and zinc can meet requirements on splitting temperature. The technology in the invention meets requirements of environmental protection, by alkaline protease powder, collagen is filled with water fully in a soaking procedure, soaking time is shortened, and reduction of the discharge amount of chromium in wastewater in a tanning process is facilitated by development of a titanium and zinc combined technology. In addition, by a chromium-free tanning process, treatment difficulty of waste chromium shavings generated in a production process can also be reduced.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for improving absorptivity of chrome tanning agent in tanning process through microwave irradiation pretreatment

InactiveCN111334623AImprove absorption rateReduce dosageProcess control/regulationTanning treatmentTanning tanningEngineering

The invention provides a method for improving the absorptivity of a chrome tanning agent in the tanning process through microwave irradiation pretreatment. The method is characterized by comprising the following steps: dissolving a chrome tanning agent in water to prepare chrome tanning liquid with certain concentration; raising the temperature to 30 to 50 DEG C by utilizing microwave irradiationunder a stirring condition; stirring and carrying out heat preservation treatment for 30 to 150 minutes at the temperature; then adding the treated chrome tanning liquid into a rotating drum and adding a certain amount of neutral salt; after the drum is rotated until the neutral salt is completely dissolved, a proper amount of pickled bare leather can be put into the drum to be subjected to chrometanning according to a conventional method, the weight of the bare leather is 100-200% of the weight of tanning liquid, and parameters such as tanning agent dosage, liquid ratio, temperature, time and pH value in the chrome tanning process are the same as those of conventional chrome tanning. By adopting the method provided by the invention, the chromium absorption rate in the tanning process canbe remarkably improved, and the chromium content in the wastewater is reduced. Materials used in the method are chemical raw materials commonly used in the tanning industry, the influence of the technical scheme on existing chrome tanning operation is small, and the practicability is high.

Owner:SICHUAN UNIV

A kind of leather production process

ActiveCN111139321BMany sites of actionIncrease shrinkage temperatureTanning treatmentPre-tanning chemical treatmentTanning tanningDioxyethylene Ether

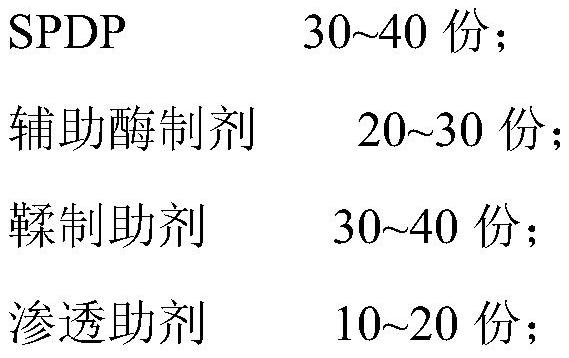

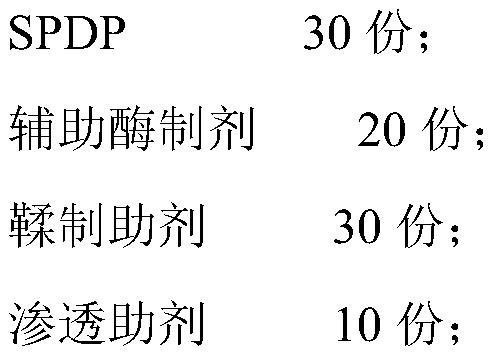

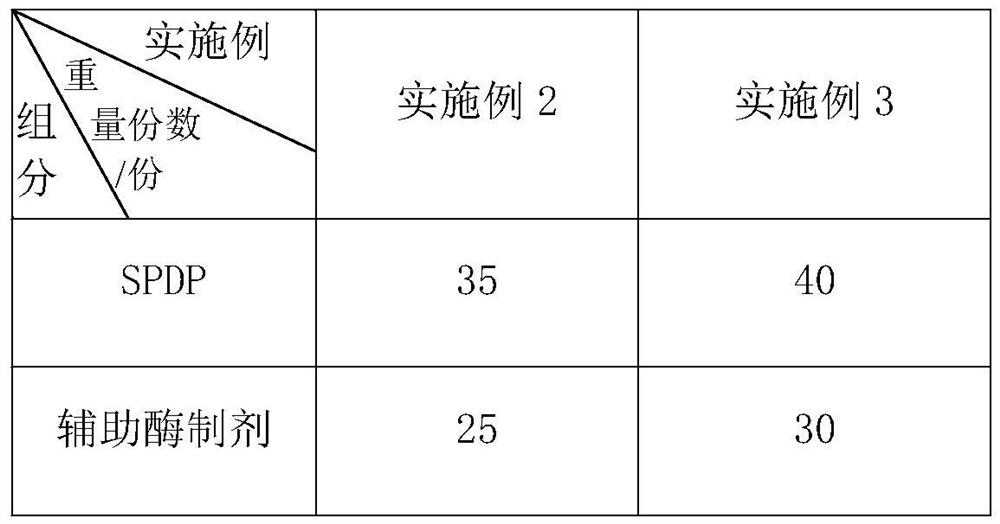

The invention discloses a leather production process and relates to the field of leather. The key points of the technology are: including the sequential immersion, degreasing, softening, tanning, processing and further processing of the raw hide; the tanning agent used in the tanning process includes the following components in parts by weight: 30~40 parts of SPDP; 20~30 parts of auxiliary enzyme preparation 30-40 parts of tanning aids; 10-20 parts of penetration aids; auxiliary enzyme preparations are selected from any one of protease and lipase; tanning aids are selected from any one of amino acids and casein; The agent is any one of fatty alcohol polyoxyethylene ether or alkali-resistant penetration agent OEP-70; SPDP, auxiliary enzyme preparation, tanning auxiliary agent and penetration auxiliary agent are mixed to obtain leather tanning agent, which has the effect of reducing water quality and environmental impact , Avoid the advantages of tannin extract dyeing, hard leather embryo, and long-term storage of mechanical properties.

Owner:漳州信德皮革有限公司

Photoprotector and/or photoimmunoprotector compositions of the skin and their uses

ActiveUS20120039828A1Prevent and minimise damaging effectPrevent and minimise reactionCosmetic preparationsOrganic active ingredientsBenzoic acidTanning tanning

The composition comprises of a component A selected from a hydroxylated derivative of benzoic acid or of cinamic acid, their esters, amides or salts, a glycoside of a hexose, and their mixtures; and a component B selected from quinic acid, shikimic acid, their alkaline metal or alkaline earth salts, their methyl esters, and mixtures of the same. This composition is suitable for protecting the skin against ultraviolet radiation coming from the sun or artificial sources, such as those used in phototherapy units and in sun tanning rooms. For application in the field of dermatology and nutrition, and, in particular, in the photoprotection of the skin and mucosa, photo-ageing and photocarcinogenesis, including protection of the immune system associated with the skin.

Owner:IND FARM CANTABRIA

baby sunbathing device

ActiveCN110843898BSimple structureReasonable designCarriage/perambulator accessoriesTanning tanningScrew thread

The invention relates to a baby sunbathing device, which comprises a baby bed body, a storage base and a screw rod. The storage base is provided with a storage cavity inside, and the four corners of the lower end of the storage base are all equipped with universal wheels. To open and close the opening and closing door of the storage chamber, the screw rod is vertically arranged and located in the middle of the side of the storage base on the opposite side of the door. The lower end of the screw rod is fixed on the storage base through a bearing seat. A seat cushion is installed on the upper side of the storage base, and a handle is installed on the upper end of the screw rod. , the upper part of the screw rod is equipped with a nut seat matched with its thread, a sleeve is arranged in the middle of one side of the crib body, the sleeve is set on the nut seat, a supporting flange is arranged on the outer periphery of the lower end of the nut seat, and the lower side of the sleeve is against the upper side of the supporting flange , the device is simple in structure, reasonable in design, easy to operate and use, and the storage base can be used for nurses to sit and rest, and can also store items. The crib is provided with shaped pillows to correct the shape of the baby's head.

Owner:XIAMEN UNIV TAN KAH KEE COLLEGE

A method for preparing high-strength hydrogel based on the principle of leather tanning

The invention discloses a method for preparing high-strength hydrogel based on the principle of tanning and tanning. The method is based on a polyvinyl alcohol-polyacrylic acid (PVA-PAA)-based hydrogel precursor, using a tanning method for tanning and assisting The mechanical action of the drum effectively combines the PVA-PAA hydrogel with the metal ion complex, further improving the structural stability of the three-dimensional network of the PVA-PAA-based hydrogel, thereby greatly enhancing the mechanical strength of the gel system. The invention proposes for the first time that the leather tanning method is applied to the field of hydrogel synthesis, and opens up a new method for the synthesis of simple and feasible high-strength hydrogel structural materials.

Owner:SHAANXI UNIV OF SCI & TECH

Method for tanning sheep boot-shoe leather using non-chromium metal composite tanning agent

InactiveCN101372718AImprove matchGood factory industrial production baseTanning treatmentSludgePollution

The invention relates to a method of tanning sheep boot leather with non-chrome metal compound tanning agent, comprising steps of pre-tanning of organic aldehyde and tanning. LTA-100 metal (chrome-free) compound tanning agent, chrome-free tanning partner D5, tanning assisting agent GM-15 and the like are adopted during the process of tanning. The invention is characterized in that: the shrinkage temperature of leather in industrialized production can be above 90 DEG C; chrome pollution and phosphorus pollution are not produced, and formaldehyde is not released; whiling dyeing, the leathers have rich colors so that the leathers are better for white and light leathers rather than the chrome tanning leathers; the tannery sludge can be directly burned without causing potential danger of hexavalent chrome; due to the good compatibility with the existing tanning technology, a special adjustment to the after-tanning technology and materials is not necessary. The invention can be used for substituting the traditional technique of leather tanning by chrome powder, meanwhile removing pollution to human and environment by chromium salts during the process and in the wastes of leather products, thus creating a new way to produce chrome-free tanning leather for tanneries.

Owner:WENZHOU UNIVERSITY

A pass-through metal salt tanning method based on ultrasonic and microwave assistance

InactiveCN107488760BTanning speed increasedAdjust process parametersTanning treatmentUltrasound - actionTanning tanning

The invention provides an ultrasonic wave and microwave assisted pass-type metal salt tanning method. The method comprises the following four steps: (1) regulating the pH value of pickled pelt firstly to be at least 3.5, extruding by adopting a roller type extruding machine, and regulating the distance between the extrusion rollers to be 40%-60% of the initial thickness of the pickled pelt; (2) enabling the grain side of the pickled pelt after extrusion to face downwards to pass through a metal salt tanning solution containing sodium chloride, tanning under the action of 40 KHz ultrasonic waves for at least 1 min, extruding the crust leather by adopting the roller type extruding machine, and further regulating the distance between the extrusion rollers to be 40%-60% of the initial thickness of the pelt; (3) repeating the operations in the step (2) for 1-3 times, and no longer extruding by adopting the roller type extruding machine after the last time tanning; and (4) performing heat preservation on the crust leather after the completion of operations in the step (3) in a microwave field for at least 2 min at the heat preservation temperature of 30-60 DEG C. The ultrasonic wave and microwave assisted pass-type metal salt tanning method is applicable to tanning adopting various metal salts, the tanning time is short, and the physical and chemical property of the obtained leather have no obvious difference compared with that obtained by adopting the conventional method; besides, the tanning solution in the method is recyclable, and waste water containing a tanning agent is not discharged during the tanning process.

Owner:SICHUAN UNIV

A salt-free, pickling-free, low-chromium combined tanning method for top-layer cowhide shoe upper leather

InactiveCN103509888BPromote absorptionReduce the content of chromium trioxideTanning treatmentChromium trioxideTanning tanning

The invention belongs to a salt-free, pickling-free, low-chromium combined tanning method for top-layer cowhide upper leather. In the conventional chrome tanning process, the content of chromium trioxide in the waste liquid after tanning with 7% chrome powder is 2000-3000mg / L, which will cause harm to the environment and human health. At the same time, the shortage of chromium resources will also lead to tanning costs. increase. In the present invention, the amphoteric polymer-based nano-composite chrome-less tanning auxiliaries and 3%-5% chrome powder are applied to the tanning process of the top-layer cowhide shoe upper leather. The content of chromium oxide is 0.21g / L, which is 80.5% lower than that tanned with 7% conventional chrome powder; the tensile strength of crust leather is 38.5% higher than that of 7% conventional chrome powder tanned, and the tear strength is increased by 50.1%. The invention can effectively reduce the content of chromium trioxide in waste water, reduce the dosage of chrome tanning agent, avoid the use of salt and acid in the tanning process, and reduce the pollution of chrome tanning waste liquid.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com