Method for tanning by jointly using compound protease soaked with water, titanium salt and zinc salt

A compound protease combined with tanning technology, which is applied in the production field of leather industry, can solve the problems such as difficult to obtain tanning effect, achieve good pH stability and thermal stability, reduce chromium emission, and reduce the effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

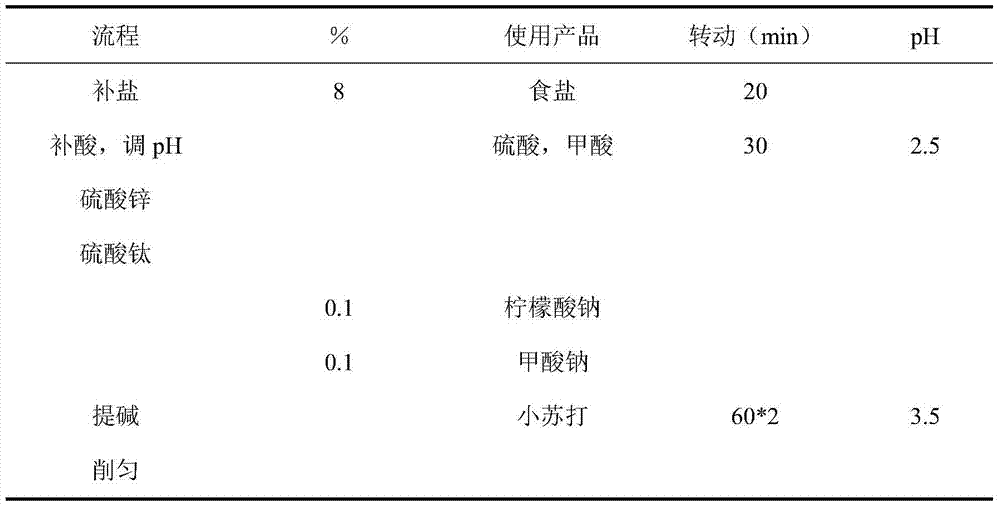

[0027] The used technological process of the present invention is as shown in table 1, and the specific operation steps of each operation of the tanning workshop section of tanning process and materials used are as follows:

[0028] (1) Soaking in water: carried out in a drum, water: 200%; temperature: 25°C; alkaline protease produced by alkalophilic bacillus strain: 0.5wt%; heavy metal-resistant protease powder: 0.1wt%; add water from the drum door, compound Protease powder, cowhide, turn for 60 minutes, stop for 20 minutes, turn for 20 minutes, stop for 50 minutes, first turn for 40 minutes in the first 2 hours, stop for 20 minutes (second time), turn for 20 minutes in the next 2 hours, stop for 40 minutes (second time), and then carry out the follow-up routine Depilation and liming and other processes.

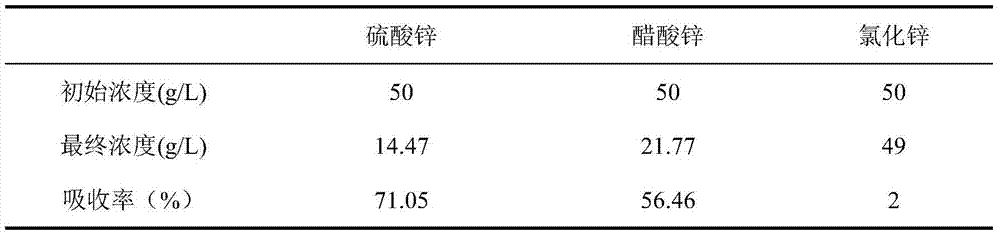

[0029] (2) pickling: carry out in the drum, the liquid ratio is 1, add NaCl8wt%, the acid used to adjust the pH is sulfuric acid and formic acid, the volume ratio of the tw...

Embodiment 2

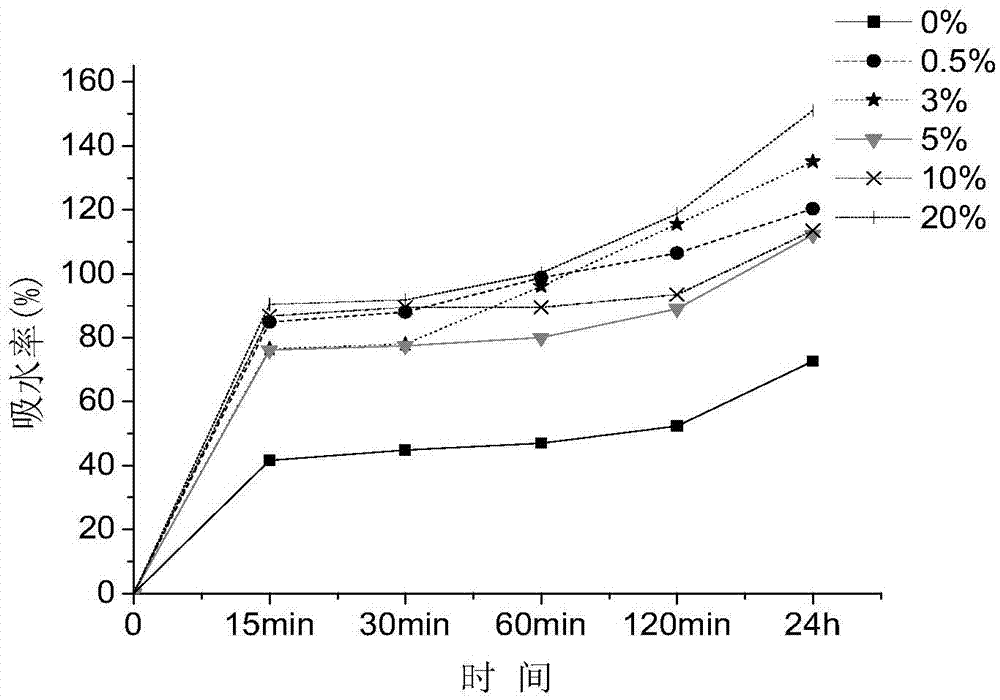

[0033] Observing the Effect of Alkaline Protease Powder on Water Soaking of Leather

[0034] As shown in Table 4, take the corresponding quality of alkaline protease powder and place it in a Kuber dish, add deionized water to keep the liquid level at the scale of 0mL, then put skin samples into different Kuber dishes, lift Lift the spherical end of the Kuber dish to completely reflux the liquid to the cylindrical end, so that the skin sample is completely immersed in the liquid, and then use plastic wrap to seal the cylindrical end to prevent moisture from evaporating. Then at 15min, 30min, 60min, 120min and 24h, lift the cylindrical end to make the liquid flow into the spherical end completely, read the scale and calculate the water absorption rate after 1min, the result is as follows figure 1 shown. It can be seen that protease powder significantly improves the water absorption rate of hides during immersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com