Nano tanning agent based on structural memory effect, preparation method and applications thereof

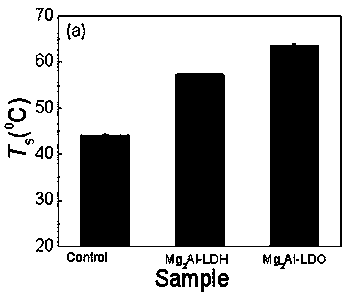

A structure-memory and nano-technology, applied in the field of leather tanning agents, can solve the environmental hazards of chromium-containing wastes, waste water pollution and other problems, and achieve the effects of enhancing adsorption performance, improving uniform dispersion, and increasing shrinkage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

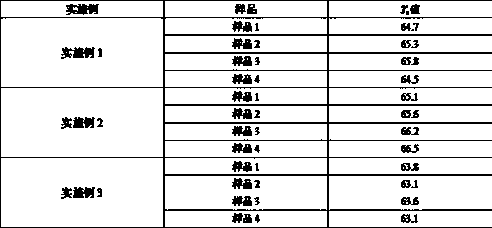

Embodiment 1

[0021] (1) Preparation of nano-tanning agent: according to the molar ratio of magnesium and aluminum elements of 2:1, magnesium nitrate and aluminum nitrate were respectively weighed and dissolved in 50 ml of water to prepare metal salt solution A, and sodium carbonate was dissolved in 100 ml of water to prepare 0.875 mol / L sodium carbonate solution B; then add solution A dropwise into solution B, adjust the pH value to 12 with 2 mol / L sodium hydroxide solution at the same time, nucleate and crystallize at a temperature of 75°C for 10 hours, centrifuge, freeze-dry, Afterwards, the obtained product was calcined at 450° C. for 4 hours to obtain a nano-tanning agent.

[0022] (2) Tanning: at room temperature, add water and softened skin with a mass ratio of 1:1 into the drum, add 8% sodium chloride with tare weight, and turn for 30 minutes; add nano-tanning agent with 3% tare weight , adjust the pH value of the bath solution to 3.0 with 2% formic acid solution, and then rotate f...

Embodiment 2

[0024] (1) Preparation of nano-tanning agent: according to the molar ratio of magnesium and aluminum elements of 2:1, magnesium nitrate and aluminum nitrate were respectively weighed and dissolved in 50 ml of water to prepare metal salt solution A, and sodium carbonate was dissolved in 100 ml of water to prepare 0.875 mol / L sodium carbonate solution B; then add solution A dropwise into solution B, adjust the pH value to 12 with 2 mol / L sodium hydroxide solution at the same time, nucleate and crystallize at a temperature of 75°C for 10 hours, centrifuge, freeze-dry, Afterwards, the obtained product was calcined at 450° C. for 4 hours to obtain a nano-tanning agent.

[0025] (2) Tanning: at room temperature, add water and softened skin with a mass ratio of 1:1 into the drum, add 8% sodium chloride with tare weight, and turn for 30 minutes; add nano-tanning agent with 3% tare weight , adjust the pH value of the bath solution to 3.0 with 2% formic acid solution, and then rotate f...

Embodiment 3

[0027] (1) Preparation of nano-tanning agent: according to the molar ratio of magnesium and aluminum elements of 2:1, magnesium nitrate and aluminum nitrate were respectively weighed and dissolved in 50 ml of water to prepare metal salt solution A, and sodium carbonate was dissolved in 100 ml of water to prepare 0.875 mol / L sodium carbonate solution B; then add solution A dropwise into solution B, adjust the pH value to 12 with 2 mol / L sodium hydroxide solution at the same time, nucleate and crystallize at a temperature of 75°C for 10 hours, centrifuge, freeze-dry, Afterwards, the obtained product was calcined at 450° C. for 4 hours to obtain a nano-tanning agent.

[0028] (2) Tanning: at room temperature, add water and softened skin with a mass ratio of 1:1 into the drum, add 8% sodium chloride with tare weight, and turn for 30 minutes; add nano-tanning agent with 5% tare weight , adjust the pH value of the bath solution to 3.0 with 2% formic acid solution, and then rotate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com