A kind of leather production process

A production process and leather technology, applied in leather softening, leather drying, leather manufacturing, etc., can solve the problems of excessive heavy metal chromium content in leather wastewater, affecting water quality and environment, and decreasing mechanical properties, and achieve good tanning effect, brightness and color. Uniform, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

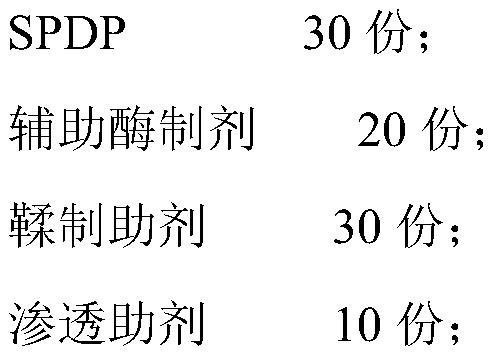

Embodiment 1

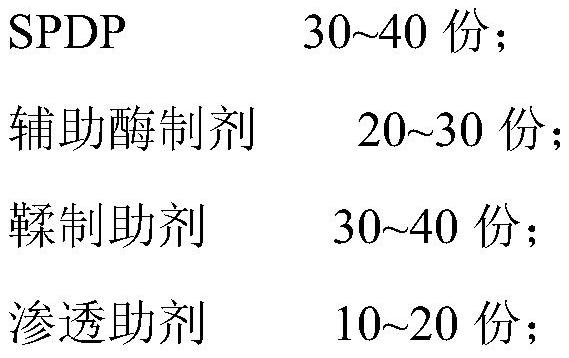

[0035] Embodiment 1: a kind of leather production process, comprises the following steps that raw hide is carried out successively:

[0036] (1) Soaking in water: First, put the raw hide in the No. 1 drum for processing, and add water to the drum according to the ratio of liquid ratio 0.8g / mL. The above liquid ratio is the ratio of the weight of the raw hide to the volume of water, and control the water temperature. 26°C, PH=8, soak for 21 hours.

[0037] (2) Degreasing: (2.1) Put the soaked leather in the meat remover to remove the flesh; (2.2) Place the peeled leather in the No. 2 drum for liming, the solution used for liming here is vulcanization Sodium, caustic soda, and slaked lime are prepared into a solution, the pH of the liming solution is controlled at 12, the temperature is 26°C, and soaked for 21 hours; (2.3) The leather after liming is delimed in the No. 2 drum, where the deliming The solution used is composed of clear water and 0.1% alcohol accounting for the vo...

Embodiment 2~3

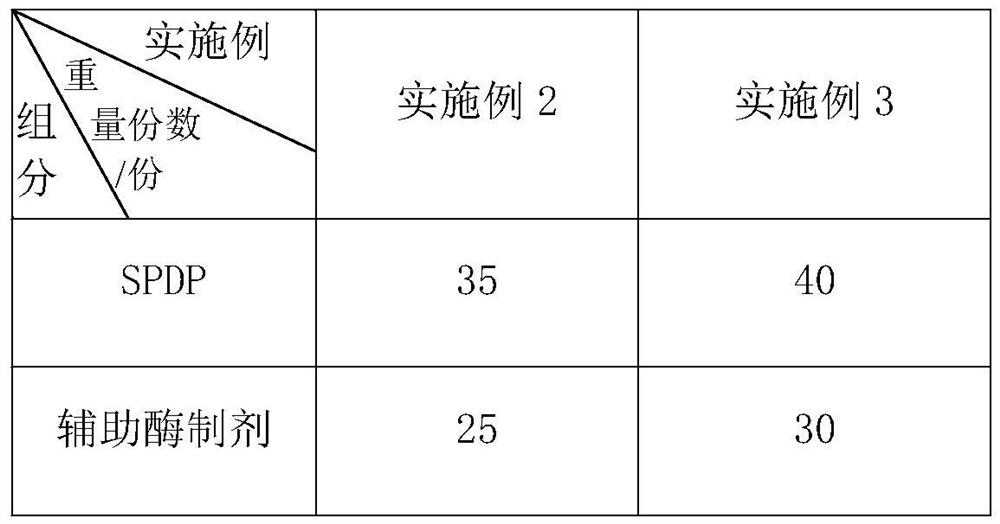

[0045] Embodiments 2-3: A leather production process, the difference from Embodiment 1 is that the components of the tanning agent in the tanning process (4) and their corresponding parts by weight are shown in Table 1.

[0046] Each component of the tanning agent and parts by weight thereof in Table 1 Examples 2 to 3

[0047]

[0048]

Embodiment 4

[0049] Embodiment 4: A leather production process, the difference from Embodiment 1 is that in the tanning process (4), the pH in the No. 3 drum is controlled to be 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com