Chrome-free Tanning Technology of Sheep Leather and Sheep Wetwhite and Sheep Leather

A processing technology, chrome-free tanning technology, applied in leather/skin/leather/hide chemical treatment equipment, small raw hide/large raw hide/leather skin/fur chemical treatment, small raw hide/large raw hide/leather/fur treatment, etc. It can solve the problems of unfavorable environmental protection, depletion, and large pollution of chrome tanning, and achieve the effects of excellent air permeability, good storage resistance, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

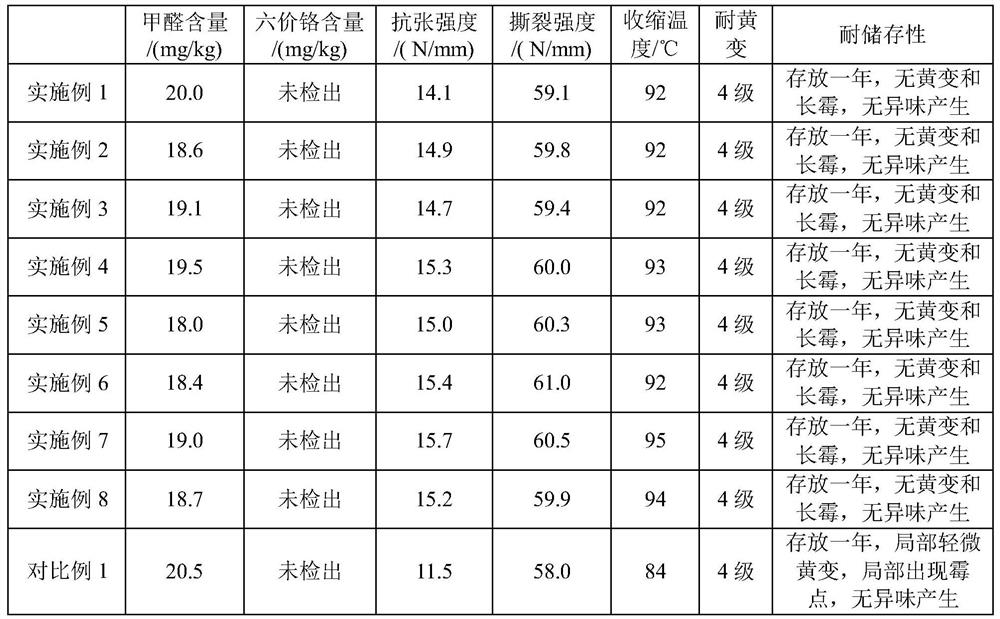

Examples

Embodiment 1

[0038] A processing technology for chrome-free tanning of sheep leather, which comprises the following processing steps:

[0039] 1. Salt throwing of raw skins: Put the raw skins into the tumbler to rotate, and turn out the salt in the raw skins;

[0040] 2. Soak in water

[0041] 2.1. Pre-soaking water: Select the six raw skins with a total weight of 21kg and put them into the drum; add 200% water at 20°C to the drum, add 0.4% anionic surfactant, 0.1% fungicide and 0.4% soda ash, turn for 5 hours, drum out, and remove the flesh from the fur;

[0042] 2.2. Main immersion: Put the skins after fleshing into an empty drum, add 200% of water at 20°C, add 0.5% of anionic surfactant, 0.2% of fungicide and 0.6% of inorganic alkali, turn for 22 hours, and take out the drum. For horses, control water for 3 hours;

[0043] 3. Alkali depilation: add sodium sulfide and water to prepare lye with two concentrations of 180g / L and 30g / L, add calcium hydroxide respectively, and adjust the c...

Embodiment 2

[0054] A processing technology for chrome-free tanning of sheep leather, which comprises the following processing steps:

[0055] 1. Salt throwing of raw skins: Put the raw skins into the tumbler to rotate, and turn out the salt in the raw skins;

[0056] 2. Soak in water

[0057] 2.1. Pre-soaking water: select the six raw skins with a total weight of 21kg and put them into the drum; add 200% water at 23°C to the drum, add 0.4% anionic surfactant, 0.1% fungicide and 0.4% soda ash, turn for 6 hours, take out the drum, and remove the flesh from the fur;

[0058] 2.2. Main immersion: Put the skins after fleshing into an empty drum, add 200% water at 22°C, add 0.5% anionic surfactant, 0.2% fungicide and 0.6% inorganic alkali, turn for 26 hours, and take out the drum. For horses, control water for 4 hours;

[0059] 3. Alkali depilation: add sodium sulfide and water to prepare lye with two concentrations of 180g / L and 30g / L, add calcium hydroxide respectively, and adjust the conc...

Embodiment 3

[0070] A processing technology for chrome-free tanning of sheep leather, which comprises the following processing steps:

[0071] 1. Salt throwing of raw skins: Put the raw skins into the tumbler to rotate, and turn out the salt in the raw skins;

[0072] 2. Soak in water

[0073] 2.1. Pre-soaking water: Select the six raw skins after the above-mentioned salt drop, with a total weight of 21kg, and put them into the drum; add 200% of 25°C water to the drum, add 0.4% anionic surfactant, 0.1% fungicide and 0.4% soda ash, turn for 7 hours, drum out, and remove the flesh from the fur;

[0074] 2.2. Main immersion: Put the skins after fleshing into an empty drum, add 200% of water at 25°C, add 0.5% anionic surfactant, 0.2% bactericide and 0.6% inorganic alkali, turn for 30 hours, and take out the drum. For horses, control water for 5 hours;

[0075] 3. Alkali depilation: add sodium sulfide and water to prepare lye with two concentrations of 180g / L and 30g / L, add calcium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com